Dust suppression belt conveyer

A belt conveyor, belt technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of high maintenance cost, dust cover can not play a dustproof role, complex maintenance process, etc., to achieve the adjustment process. Simple, suppressing dust scattering, and increasing profitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can fully understand the purpose, features and effects of the present invention.

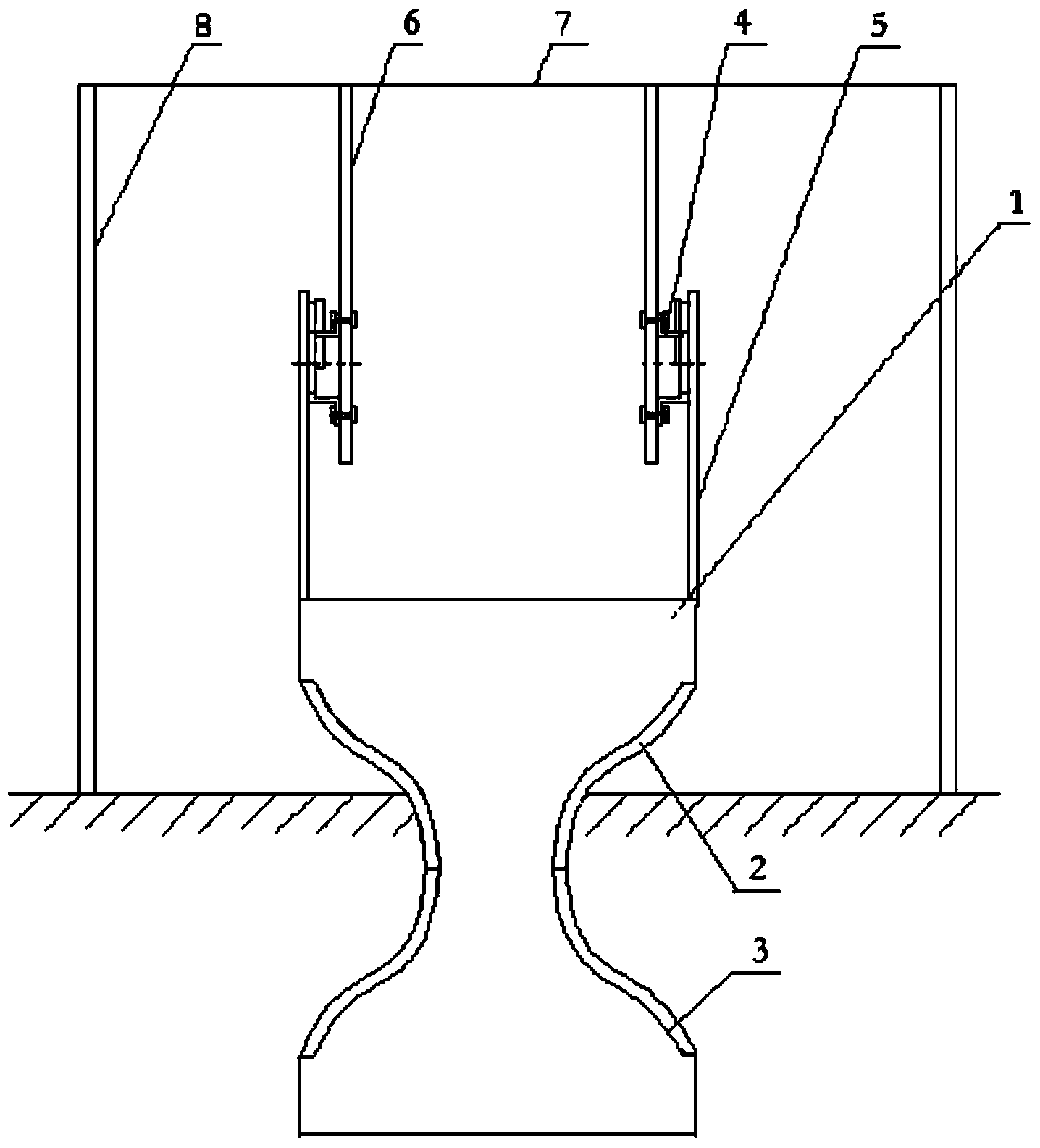

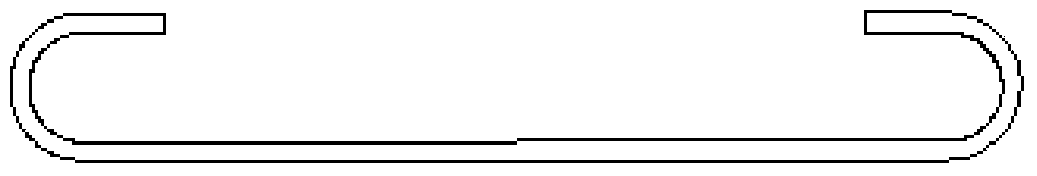

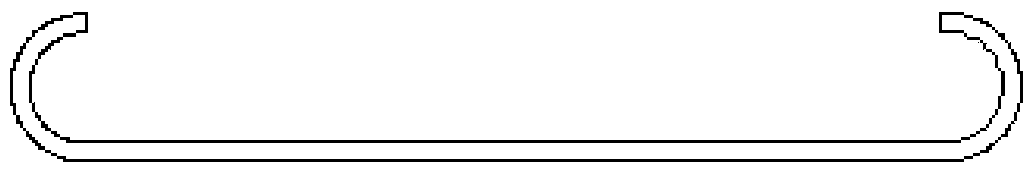

[0026] The belt conveyor provided in a preferred embodiment of the present invention comprises belt 1 and dust cover, as figure 1 As shown, the opener 2 and the closer 3 are arranged at the blanking end of the belt conveyor, the opener 2 is arranged above the closer 3, and the belt 1 passes through the blanking end sequentially from top to bottom Opener 2 and closer 3. When the belt conveyor transports materials, the load-bearing belt of the belt 1 and the dust suppression plate are in the same plane; The dust boards are not in the same plane; when the belt 1 passes through the opener 3, both sides of the belt 1 are laid flat, and the load-bearing belt of the belt is in the same plane as the dust suppre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com