Dust collection device for building site

A technology of dust removal device and construction site, which is applied in construction, building structure, construction material processing and other directions, can solve the problems of inability to handle dust, insufficient control range, waste of water, etc., to solve the problem of dust, high use value, Easy to maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

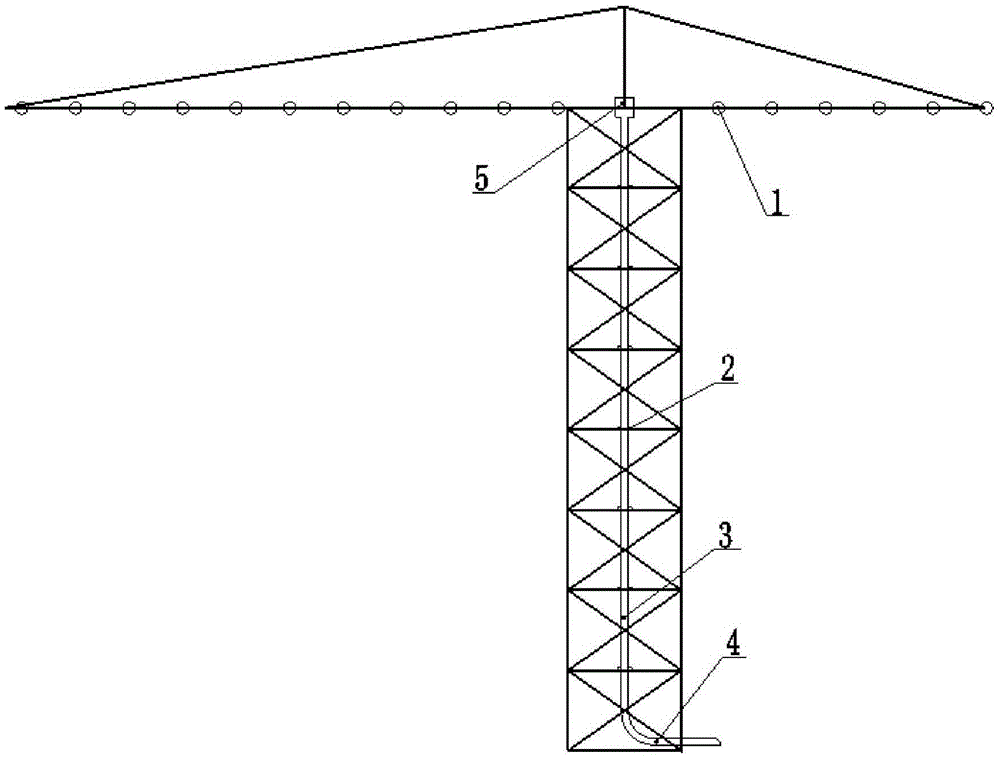

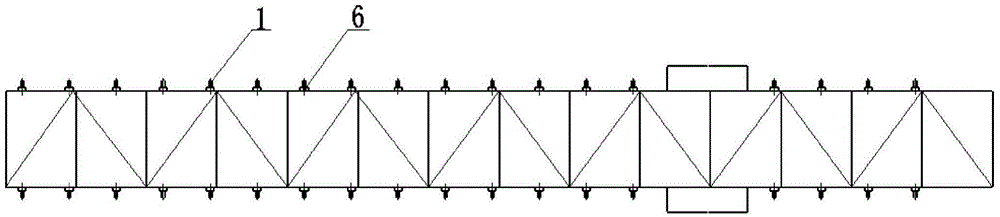

[0017] The main contents of the system include nozzle 1, clamp 2, pressure-resistant water delivery hose 3, steel pipe 4, rotary joint 5, nozzle support 6, ball valve 7, pressure gauge 8, multi-stage centrifugal water pump 9, motor 10, water filter Device 11, water tank 12, elbow 13, copper sleeve 14, O-ring 15, straight pipe 16, lock nut 17 and limit screw 18, the device uses the tower crane on the construction site to fix the pipeline on On the standard section of the tower crane, the pipeline is connected to the spray boom at the center of the slewing support of the tower crane through the rotary joint 5. The spray boom is fixed on the tower crane arm frame, and a certain number of nozzles 1 are evenly distributed on the spray boom. 6 is fixedly installed on the spray rod, and the nozzle 1 is fixed on the nozzle support 6, so that the water of the multi-stage centrifugal water pump 9 can be sent to tens or even hundreds of meters in the air, and through the rotation of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com