Method for processing kettle-liquid of acrylonitrile quench tower lower portion

A treatment process and a technology for a quenching tower, which is applied in the field of the treatment process of the lower section of the acrylonitrile quenching tower, and can solve the problems of complex composition and many impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

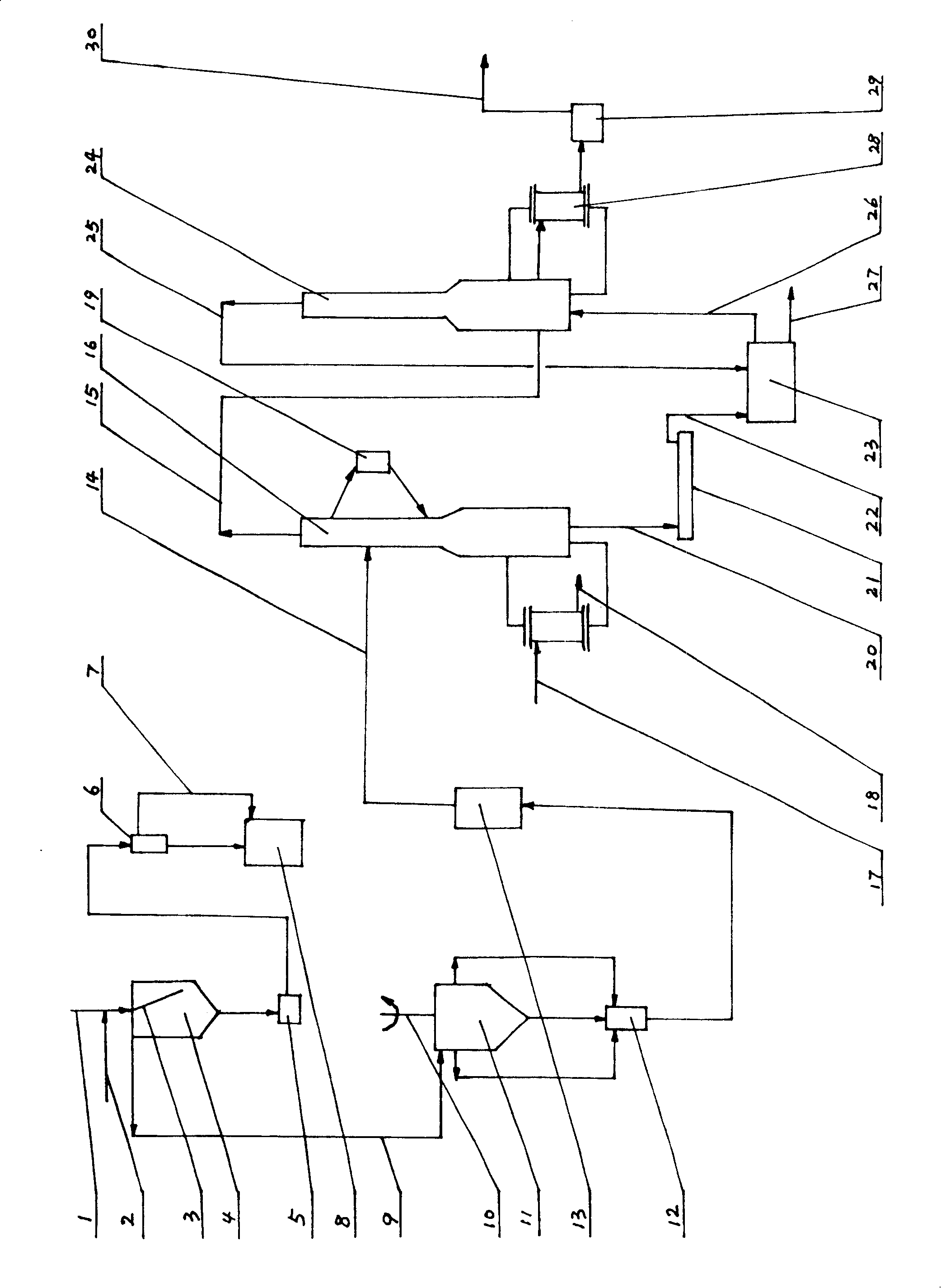

[0007] The tank liquid treatment device in the lower section of the acrylonitrile quenching tower includes: liquid inlet 1, dosing port 2, partition 3, settling tank 4, mud pump 5, settling filter 6, overflow port 7, filtrate tank 8, water outlet 9 , mixer 10, centrifugal filter tank 11, centrifugal filter 12, adsorption tank 13, concentration tower liquid inlet 14, recovery tower reboiler steam inlet 15, concentration tower 16, concentration tower reboiler steam inlet 17, concentrated Tower reboiler condensate outlet 18, organic heavy component collector 19, concentrated ammonium sulfate liquid outlet 20, drying bed 21, ammonium sulfate inlet 22, ethanol washing tank 23, recovery tower 24, ethanol steam outlet 25, ethanol into the tower Port 26, finished ammonium sulfate port 27, recovery tower reboiler 28, vacuum pump 29, vacuum pump outlet 30.

[0008] Firstly, the still liquid in the lower section of the quench tower that has been simply settled for several hours is introd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com