Single-tooth claw pricking type sundries removing device

A single-tooth, debris technology, applied in the field of single-tooth claw-type debris removal device, can solve the problems of reducing the output of coal mills, removing soft debris in difficult fuel, affecting civilized production, etc., to protect the motor reducer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of the single-tooth claw-type impurity removal device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

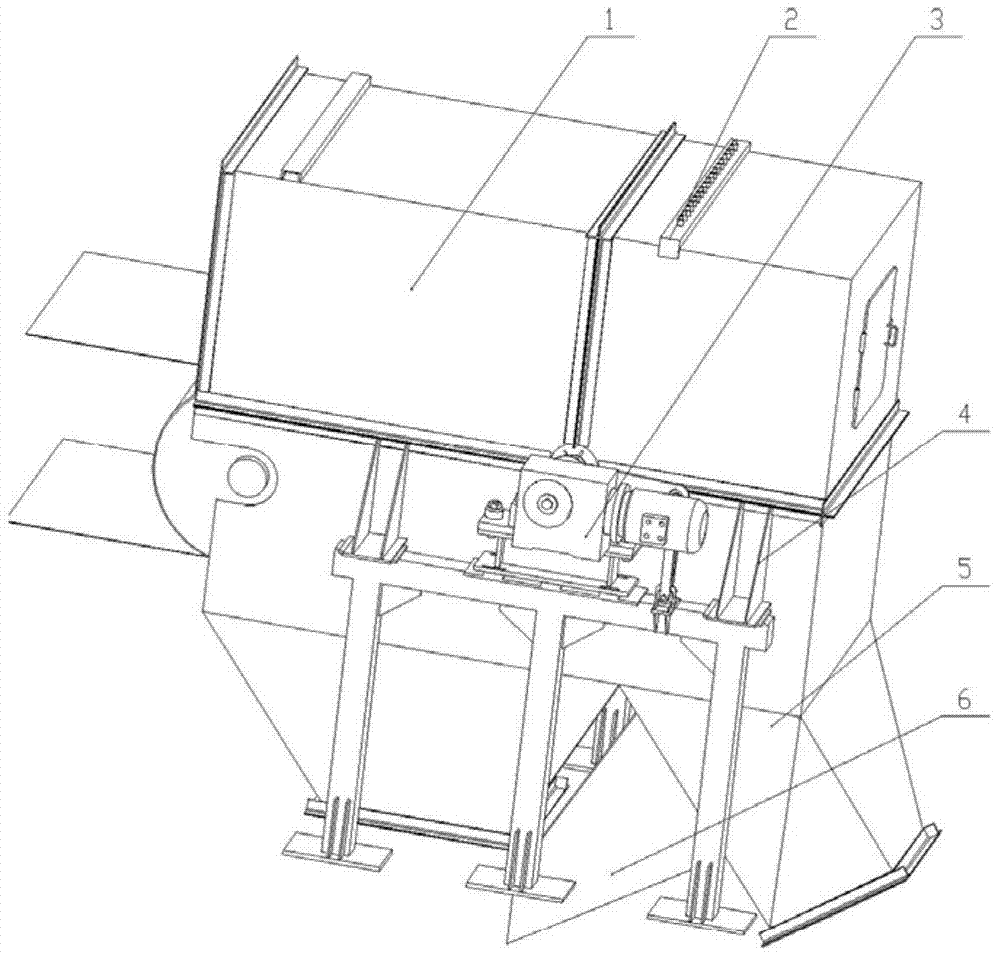

[0022] see figure 1 , figure 2 As shown, the single-tooth claw-type impurity removal device of the preferred embodiment of the present invention mainly includes: single-tooth claw-type impurity removal device, which is mainly composed of a box assembly 1, a comb assembly 2, a drive, Supporting device assembly 3 holder body 4, debris collection bucket 5, material recovery bucket 6, plow coal body 7, single-tooth claw separation body 8, material baffle plate 9, elastic vibration recovery grate 10, two outriggers 11. Wherein, the two supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com