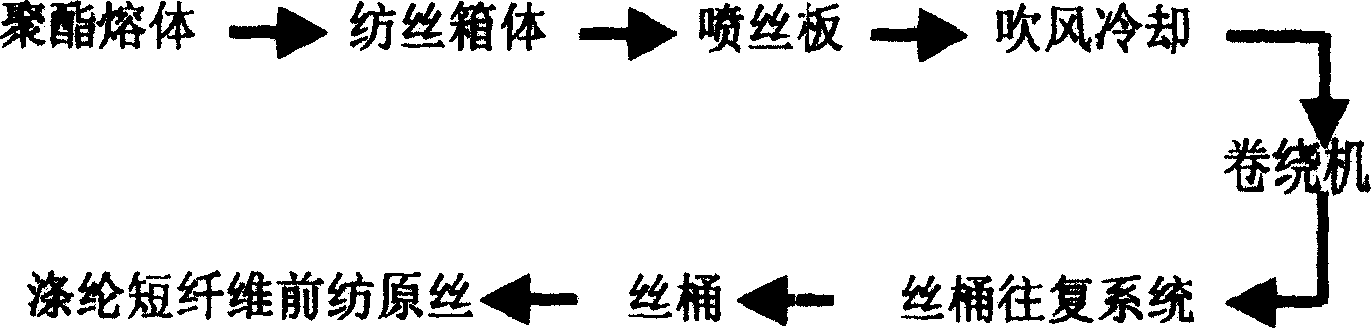

Preparation method of low damping internal circular blow multipore spinning fiber

A low-damping, ring-blown technology, applied in the field of polyester production technology, can solve the problems of high investment cost, short service life, complicated production process of blowing head, etc., and achieve low one-time investment, low production equipment requirements, and simple maintenance process costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In the process of preparing 1.33dtex (spinneret holes: 3780) fibers with intrinsic viscosity of 0.63-0.65 polyester melt as raw material, in addition to other steps in the prior art, the cooling air main air duct of the inner ring blowing process Wind pressure ≤ 2500pa.s, the blower head is wire mesh plus porous metal rectifier, the blowing wind speed is 1~2m / s, the inlet pressure of the blower head rectifier is 1500pa.s, the rectification pressure drop is 1200pa.s, and the wind pressure of the hair dryer is 200~ 300pa.s. The performance of the obtained product is good, and the physical indexes of the obtained silk are shown in Table 1.

Embodiment 2

[0020] In the process of preparing 1.56dtex (spinneret holes: 3780) fibers using polyester melt with an intrinsic viscosity of 0.63-0.65 as raw material, in addition to other steps in the prior art, the cooling air main air duct of the inner ring blowing process Wind pressure ≤ 2500pa.s, the blower head is wire mesh plus porous metal rectifier, the blowing wind speed is 1~2m / s, the inlet pressure of the blower head rectifier is 1600pa.s, the rectification pressure drop is 1200pa.s, and the wind pressure of the hair dryer is 200~ 300pa.s. The performance of the obtained product is good, and the physical indexes of the obtained silk are shown in Table 1.

Embodiment 3

[0022] In the process of preparing 1.56dtex (spinneret holes: 4250) fibers with intrinsic viscosity of 0.63-0.65 polyester melt as raw material, in addition to adopting other steps in the prior art, the cooling air main air duct of the inner ring blowing process Wind pressure ≤ 2500pa.s, the hair dryer is made of wire mesh and porous metal rectifier, the wind speed is 1~2m / s, the inlet pressure of the hair dryer rectifier is 1600pa.s, the rectification pressure drop is 1200pa.s, and the wind pressure of the hair dryer is 300~ 350pa.s. The performance of the obtained product is good, and the physical indexes of the obtained silk are shown in Table 1. Table 1 The comparison of the performance index of the polyester staple fiber pre-spinning precursor made by the present invention and the prior art *

[0023] sample

dtex

uneven linear density

rate cv%

Cn.dtex

cv%

elonga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com