Composite aqueous ink

A water-based, ink-based technology, applied in inks, household appliances, applications, etc., can solve the problems of being easily affected by factors such as oxidation, temperature, light, humidity, etc. Appropriate color, good wear resistance and other properties, the effect of stitch water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

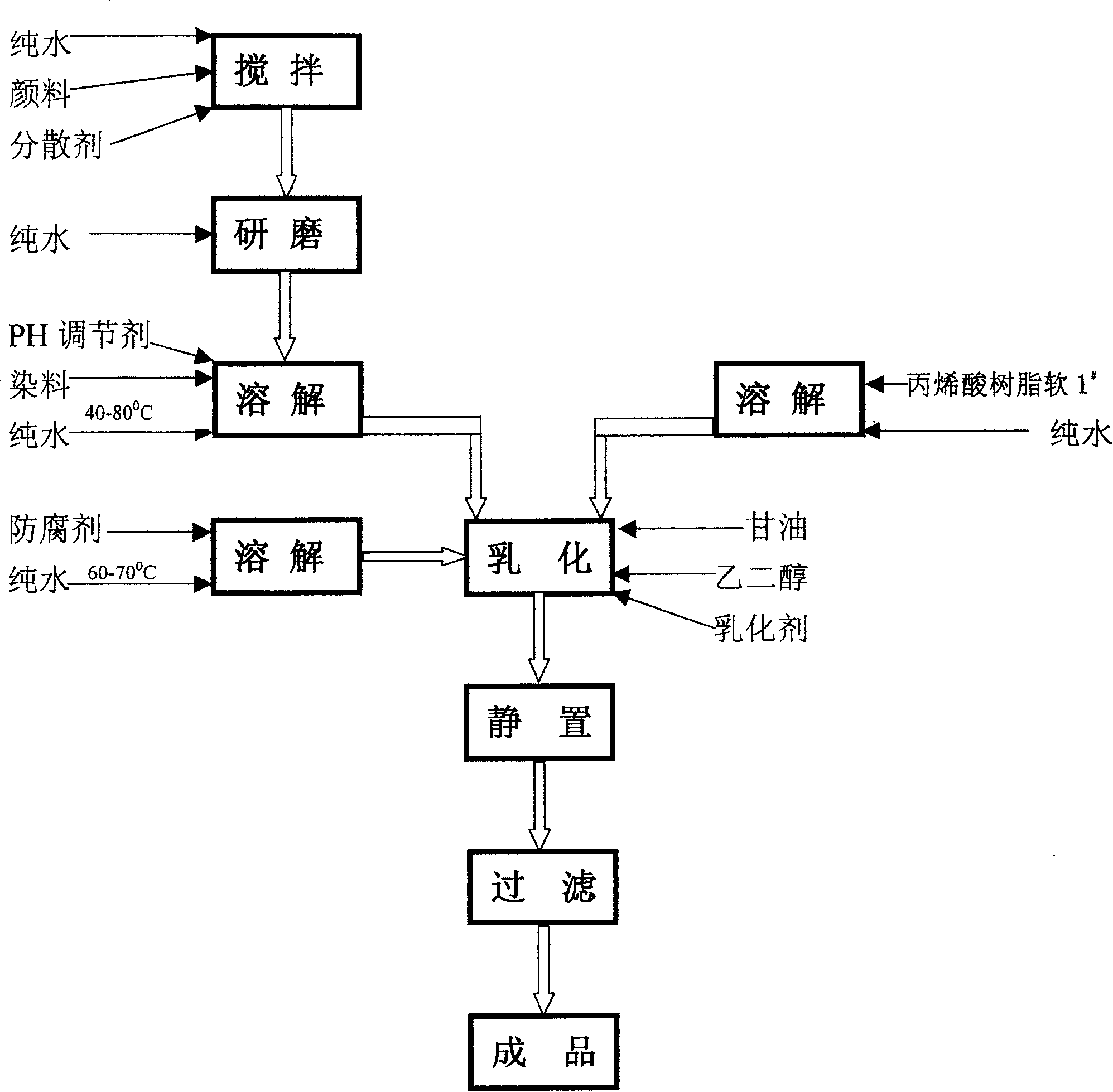

[0021] Refer to the process flow chart to prepare 100kg compound water-based ink:

[0022] (1) Put 3.5kg of high-pigment carbon black into 4.4kg of pure water, then add 0.3kg of NNO, stir well to dissolve it, add pure water to grind until the fineness is below 10μm, and the amount of pure water added is 5.5kg ;

[0023] (2) Dissolve the ground solution, 5kg of direct sunfast tan G-200 and 7kg of triethanolamine in 45kg of hot pure water at a temperature of 40-80°C to obtain solution I for subsequent use;

[0024] (3) Soften 0.5kg of acrylic resin to 1 # Put into 10kg of pure water and dissolve to obtain acrylic resin soft 1 # solution, spare;

[0025] (4) Add 0.3kg of phenol into 5kg of hot pure water at a temperature of 60-70°C to dissolve, then add the above-mentioned acrylic resin soft 1 # Solution, solution I, 10kg glycerin, 6kg ethylene glycol and 0.2kgOP emulsifier carry out emulsification;

[0026] (5) After emulsification, standing and filtering, the finished prod...

Embodiment 2

[0028] Refer to the process flow chart to prepare 100kg compound water-based ink:

[0029] (1) Put 5.5kg of high-pigment carbon black into 8kg of pure water, then add 0.6kg of NNO, stir fully to dissolve it, add pure water to grind until the fineness is below 10 μm, and the amount of pure water added is 9kg;

[0030] (2) Put 4kg of direct sunfast tan G-200, the solution after grinding and 6kg of triethanolamine into 40kg of hot pure water at a temperature of 40-80°C to dissolve to obtain solution I, which is set aside;

[0031] (3) Soften 0.6kg of acrylic resin to 1 # Put into 6kg of pure water and dissolve to obtain acrylic resin soft 1 # solution, spare;

[0032] (4) Add 0.2kg of phenol into 3kg of hot pure water at a temperature of 60-70°C to dissolve, then add the above-mentioned acrylic resin soft 1 # Solution, solution 1, 15kg glycerol, 9kg ethylene glycol and 0.3kg Tween (tween) carry out emulsification;

[0033] (5) After emulsification, standing and filtering, the...

Embodiment 3

[0035] Refer to the process flow chart to prepare 100kg compound water-based ink:

[0036] (1) Put 7kg of high-pigment carbon black into 10kg of pure water, then add 1kg of NNO, stir fully to dissolve it, add pure water to grind until the fineness is below 10 μm, and the amount of pure water added is 9kg;

[0037] (2) Put 3kg of direct sunfast tan G-200, the solution after grinding and 3kg of sodium hydroxide into 30kg of hot pure water at a temperature of 40-80°C to dissolve to obtain solution I, which is set aside;

[0038] (3) Soften 1kg of acrylic resin # Put into 6kg of pure water and dissolve to obtain acrylic resin soft 1 # solution, spare;

[0039] (4) Add 0.2kg of phenol into 2.5kg of hot pure water at a temperature of 60-70°C to dissolve, then add the above-mentioned acrylic resin soft 1 # Solution, solution 1, 20kg glycerin and 13kg ethylene glycol and 0.5kg Span (span) carry out emulsification;

[0040] (5) After emulsification, standing and filtering, the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com