Transfer printing method

A transfer film and adhesive technology, which is applied in the direction of transferring ink from the original, can solve the problems of whether the processed object is completely cooled in the space, the processing quality is difficult to guarantee, and the viscosity is damaged, etc., so as to achieve beautiful and clear product patterns , shorten the constant temperature drying, and solve the effect of deformation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

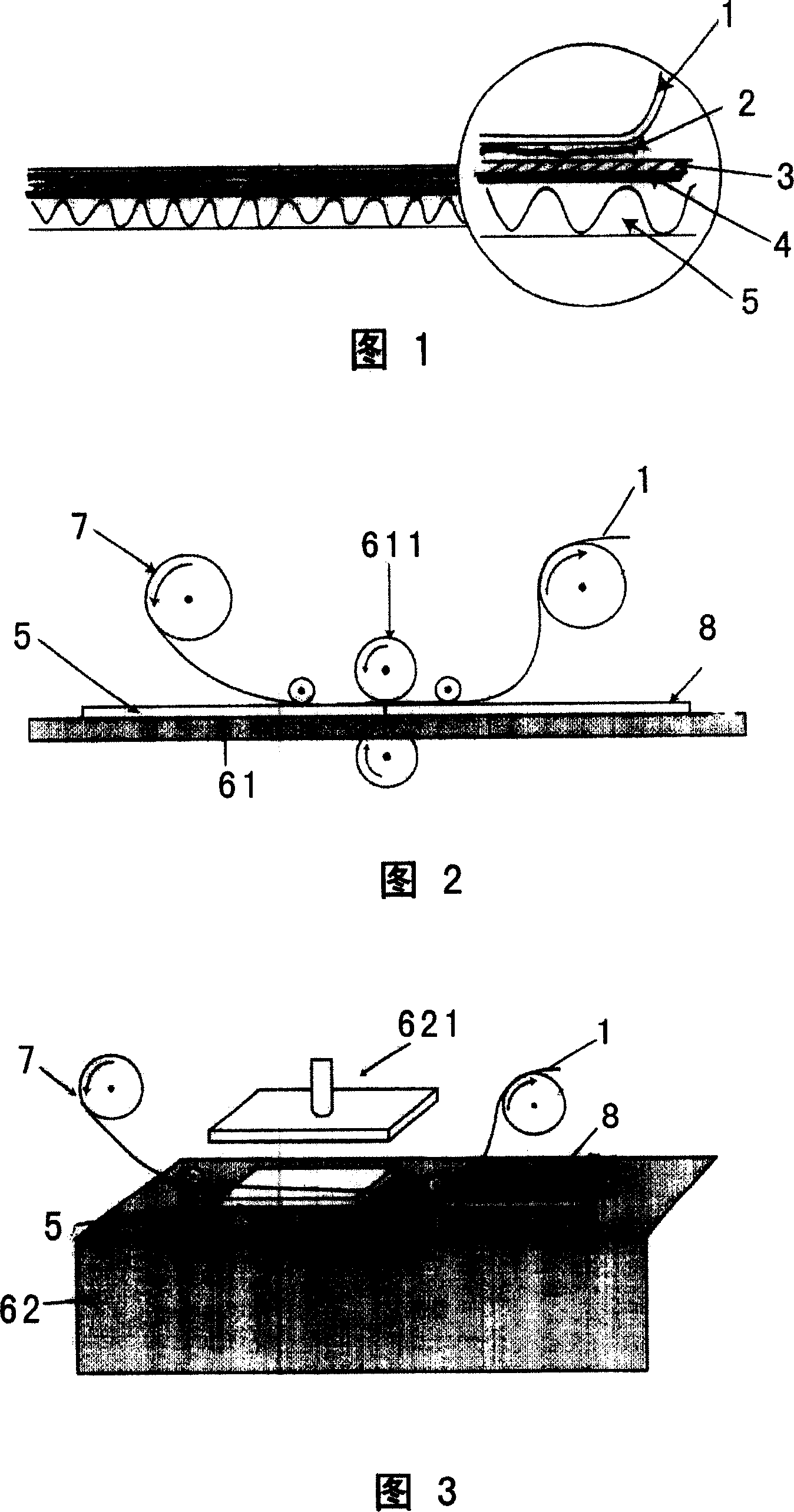

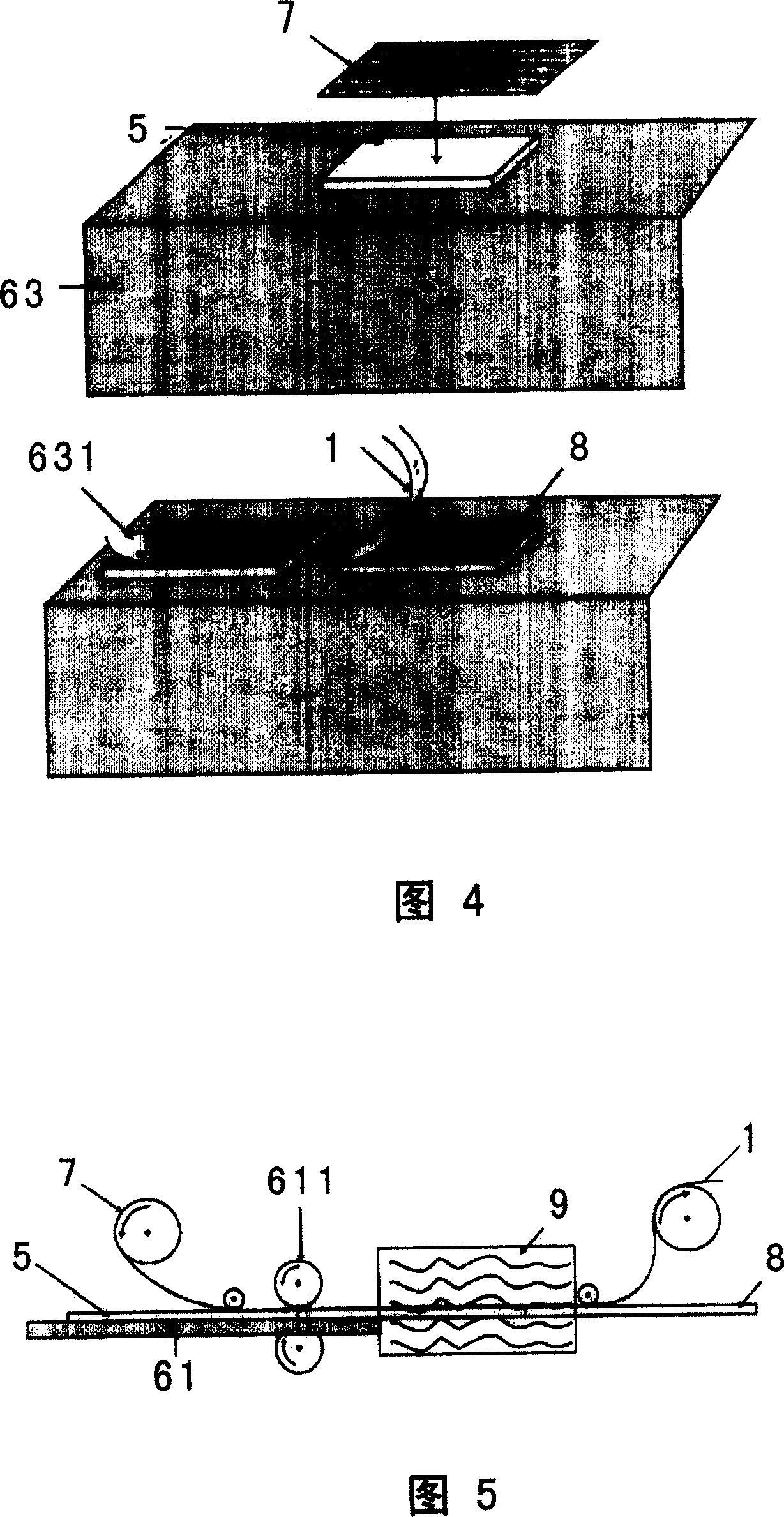

[0027] Roller type room temperature transfer printing: as shown in Figure 2, apply a layer of universal glue on the surface of product 5 by roller glue coating at a temperature of 10-40°C, semi-dry for later use, until the universal glue volatilizes to 40%-60%, touch it by hand Non-sticky shall prevail. Glue can also be applied by spraying glue, manually brushing glue, etc. Use ordinary transfer film to place the processed

[0028] A good product surface is sent to the roller type transfer machine 61, and is rolled with a pressure roller 611, so that the transfer film 7 and the product are pressed at the same time, and the pressure reaches 50----100 kg, and they are firmly combined under the action of pressure. The pressure standard adjusts the wheel base and pressure of the pressure wheel according to the material and thickness of the product. Because there is a release agent on the transfer film, the plastic film 1 can be easily removed at the same time or a few seconds af...

Embodiment 2

[0030] Flat-bed pressure transfer printing at room temperature: as shown in Figure 3, use a glue machine to coat a layer of universal glue on the surface of the workpiece 5 at a temperature of 10-40°C. The same as the first embodiment, just send the processed product into the flat-bed pressure transfer printing Machine 62, utilizes plate 621 to apply certain pressure to product, and pressure reaches about 50-100 kilograms, and regulates pressure depending on its product size material etc. After the product is pressed for a few seconds, it can be completely attached to the processed object, and the transfer film 1 can be torn off to obtain the finished product 8 .

Embodiment 3

[0032] Push-and-squeeze transfer printing: as shown in Figure 4, at a temperature of 10-40°C, coat a layer of universal glue on the surface of the workpiece 5 for semi-drying. The coated universal glue volatilizes to 40%-60%. The hand is not sticky to the touch; place the half-dried processed product on the workbench 63 and cover the transfer film 7; on the surface of the product covered with the transfer film, push it hard with the hand 631 evenly, and the pressure reaches 5 ---10 kg; tear off the transfer film 1 when the product is completely and evenly pressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com