Inductive coupling plasma device

A technology of inductive coupling and plasma, applied in the direction of plasma, circuits, electrical components, etc., can solve the problems of asymmetry of plasma density, uneven wafer etching rate, unstable semiconductor processing quality, etc., and achieve a small difference in speed , Etching rate is uniform, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

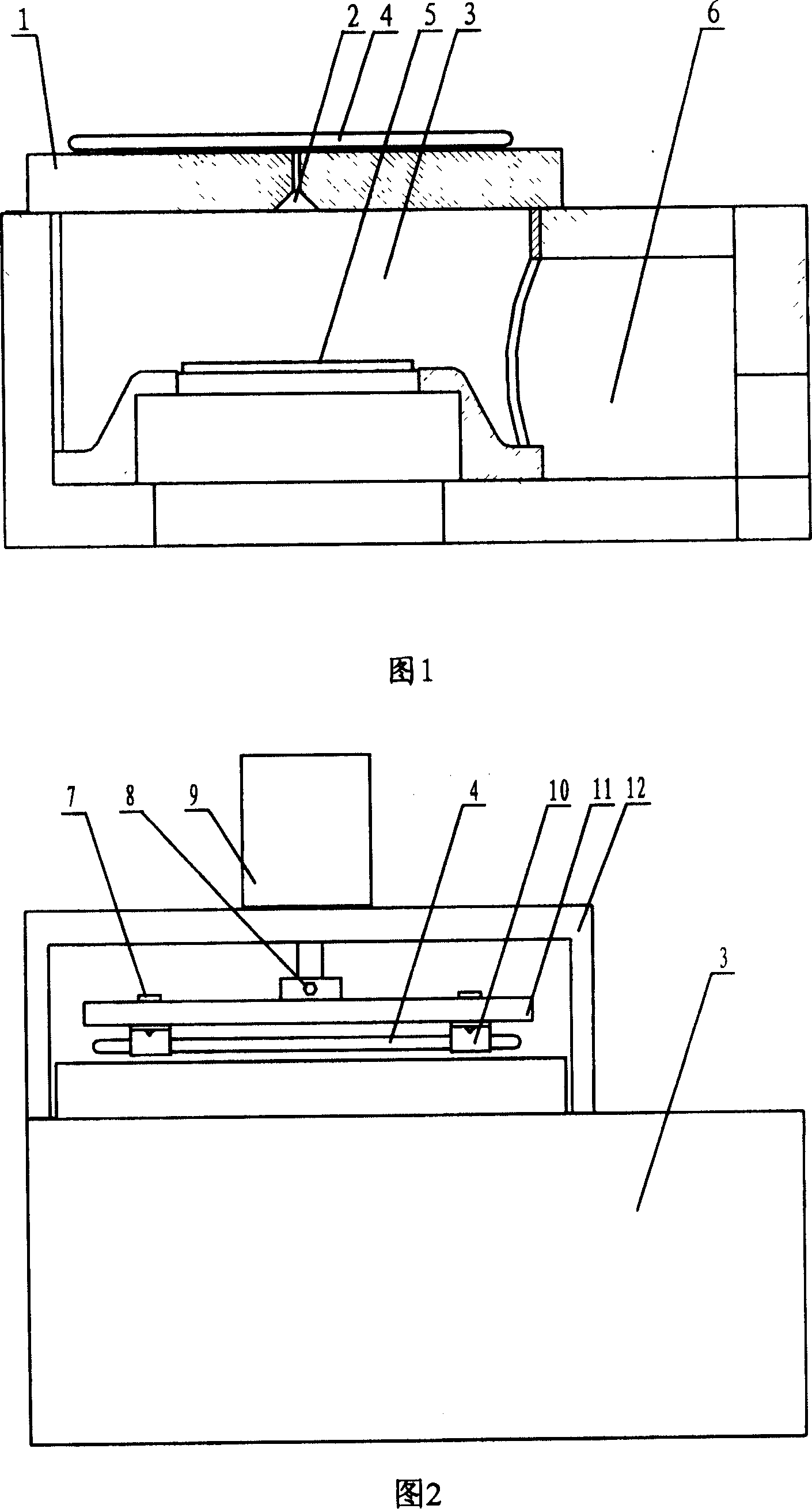

[0011] The specific implementation of the inductively coupled plasma device of the present invention is shown in FIG. 2: it includes an inductively coupled plasma cavity, an inductively coupled coil 4 and a coil rotating device. The inductive coupling coil 4 is located above the outside of the inductively coupled plasma cavity. The inductive coupling coil 4 is installed on the coil rotating device, and the input and output ends of the inductive coupling coil 4 are connected to the power supply through brushes. The rotating device is fixed on the inductively coupled plasma cavity. The coil rotating device includes a motor 9, a fixed plate 11 and a bracket 12. The bracket 12 is fixed on the inductively coupled plasma chamber, the shaft end of the motor 9 is mounted downward on the beam of the bracket 12, the motor 9 axis is connected to the center hole of the fixed plate 11, and the screw 8 is fixed, and the inductive coupling coil 4 passes through the clamp 10 and The fixing screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com