Thread spraying structure

A technology of spinning and spinneret, which is applied in the field of spinning, and can solve the problems of increasing safety accidents, being unable to be carried away by other filaments, and broken filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

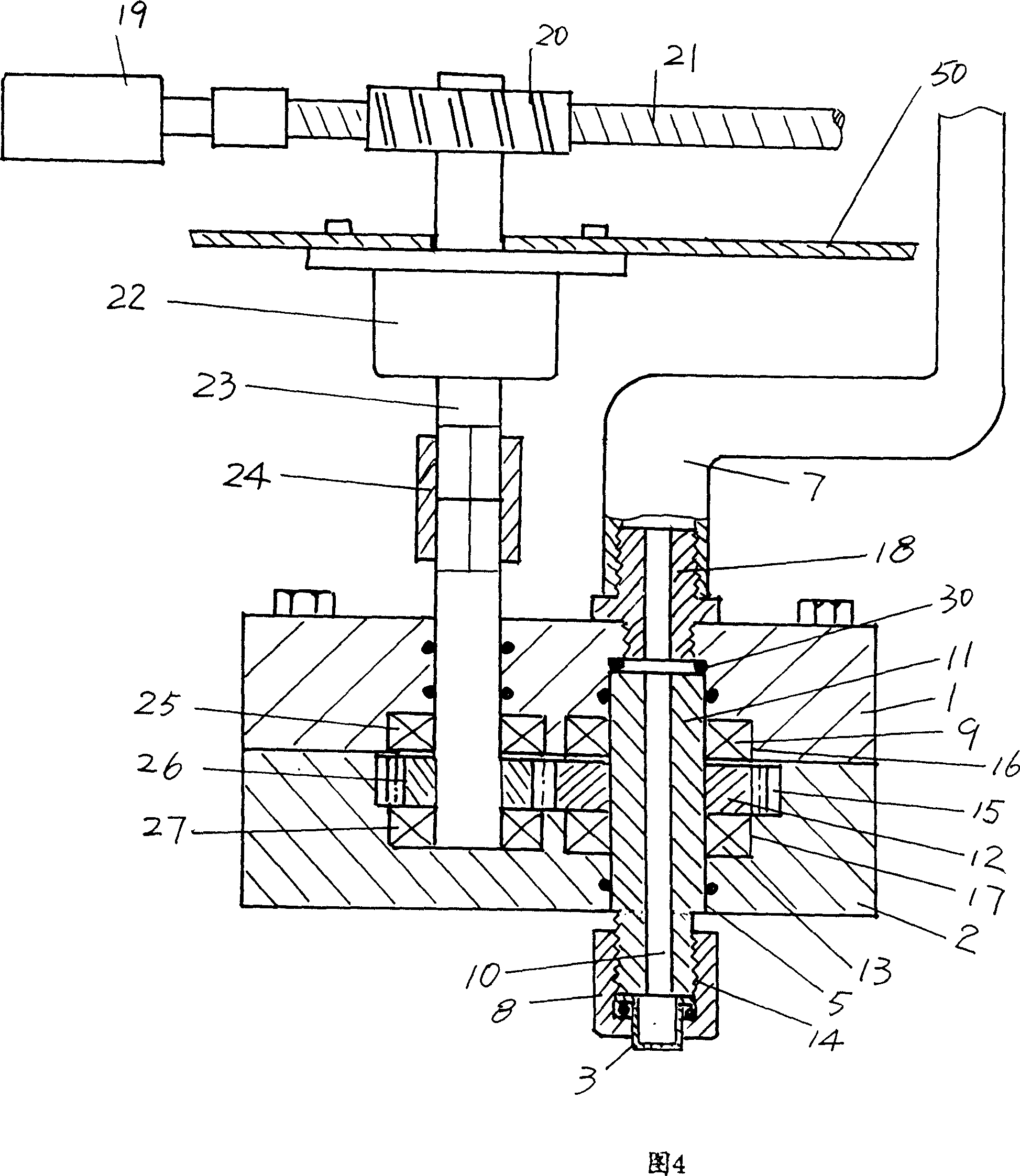

[0037] The examples described below are convenient for understanding the spinning mechanism of the present invention but do not limit the content of the present invention.

[0038] In Fig. 4, this figure is the form that the applicant exemplifies and is suitable for a single spinneret 3, because the spinneret mechanism only includes a spinneret 3, so the rotating device also only has one set, and the sprayer of this structure The wire mechanism does not need to adopt the separator plate 28 shown in Fig. 5 and Fig. 6 that the applicant will mention below. In addition, for the spinning mechanism that only has a single spinneret cap 3, those skilled in the art can fully understand It is suitable for processing viscose fiber.

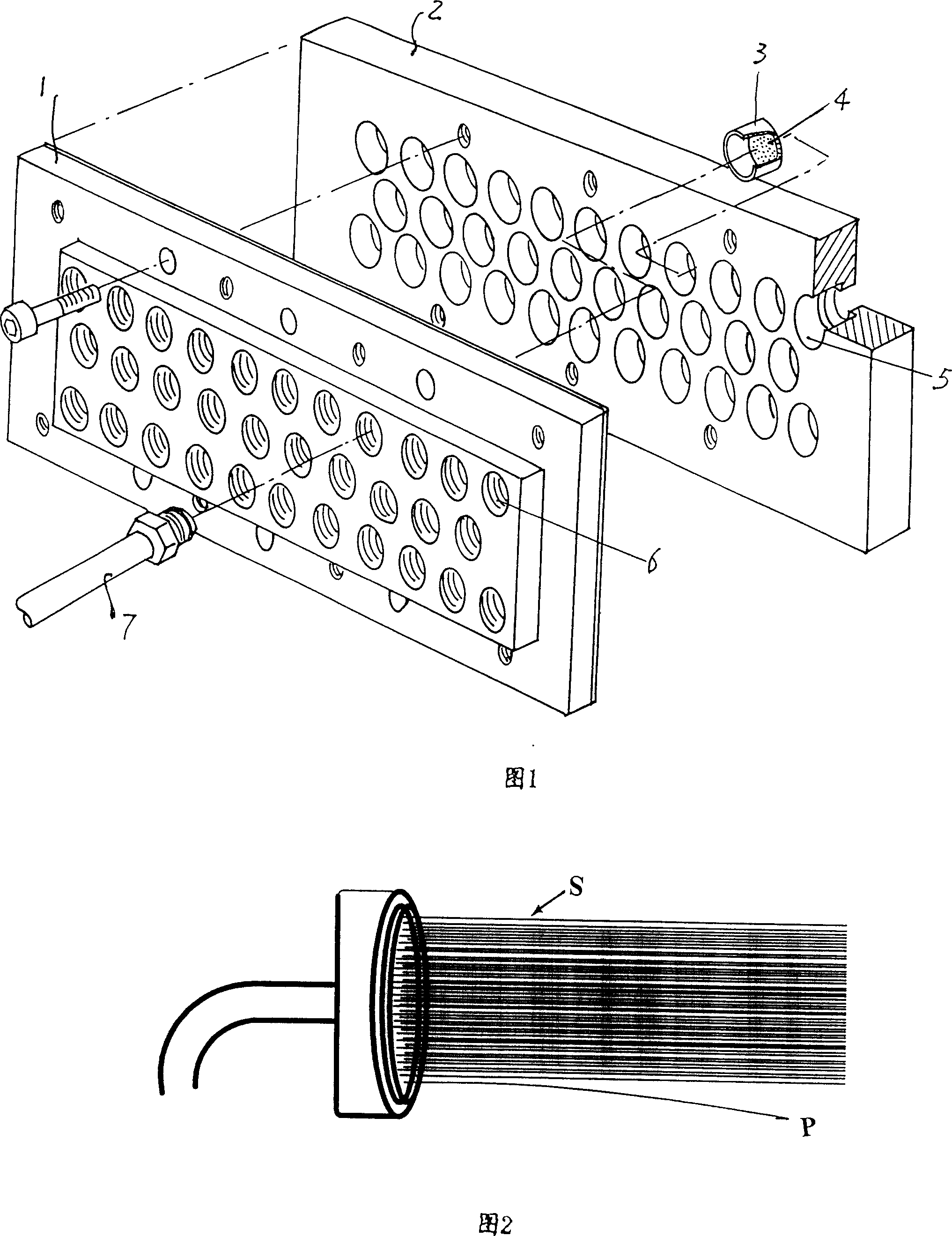

[0039] The spinneret holder 1 and the spinneret 2 are shown as rectangular, and the circular shape is also applicable. The spinneret 2 and the spinneret seat 1 are fixed face to face by bolts. On the spinneret 2, there is a spinneret seat chamber 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com