Section steel rolling mill guide

A rolling mill and section steel technology, applied in the field of rolling mill wire and bar guide, can solve the problems of high replacement cost, section steel warping and roll wrapping, adverse effects of rolling mill, etc., and achieve the effect of avoiding wire bar wrapping and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

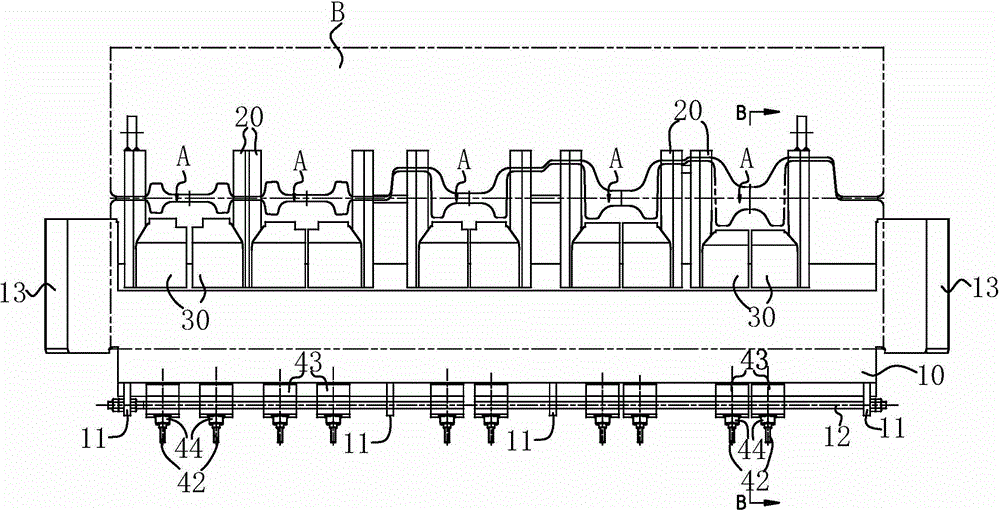

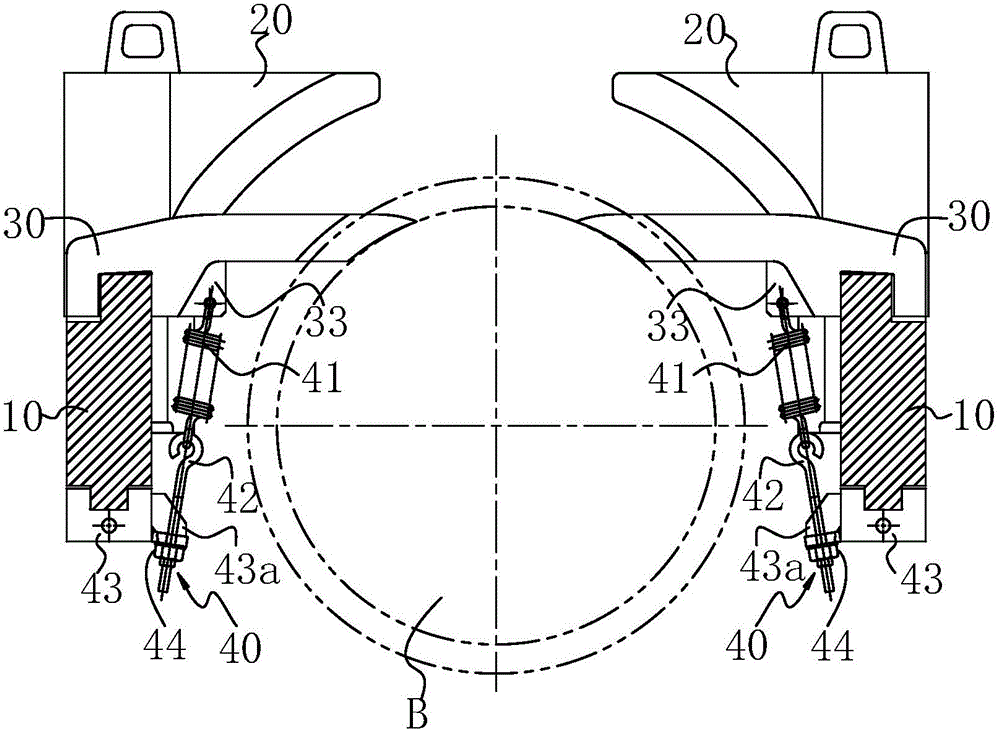

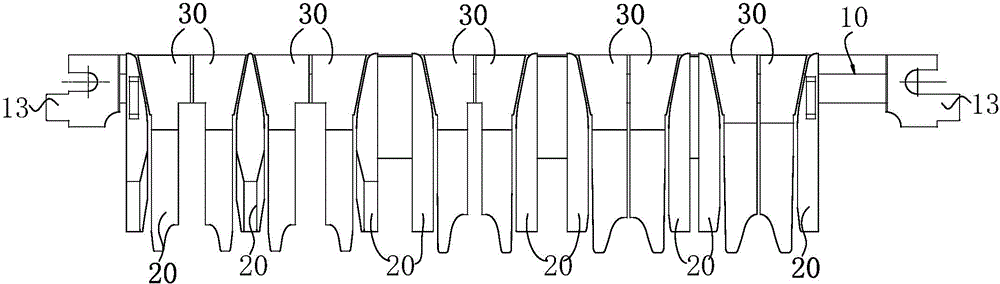

[0016] combine Figure 1 to Figure 8 , the present invention is further explained in detail:

[0017] A section steel rolling mill guide, including a guide beam 10 for connecting with a rolling mill frame, on which a side plate 20 is arranged, and the side plate 20 and the guide beam 10 form a detachable fit and are arranged at intervals A guard plate 30 is arranged between the side plates 20, and the guard plate 30 forms a detachable fit with the guide beam 10. The height of the guard plate 30 is set adjacent to the bottom of the material chamber A. A guard plate 30 is arranged between them, and the side adjacent to the roll B of the guard plate 30 is placed on the bottom of the cavity A of the material chamber. One side of the roller is built on the bottom of the material chamber A, and the billet after rolling is transported to other stations for billet processing along the guard plate 30, so as to avoid the phenomenon that the billet to be processed is wrapped around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com