Method for producing a grab handle with magnetism

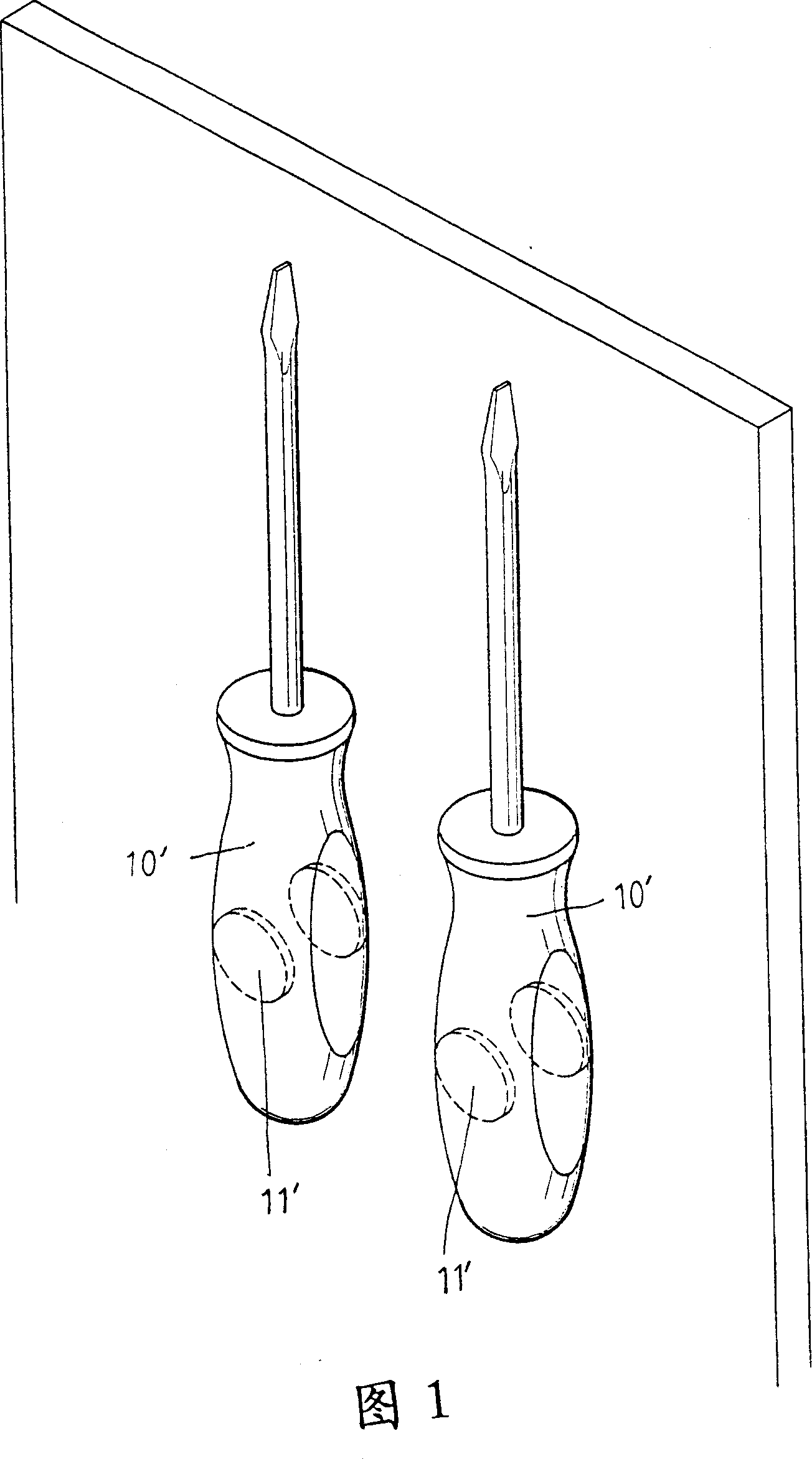

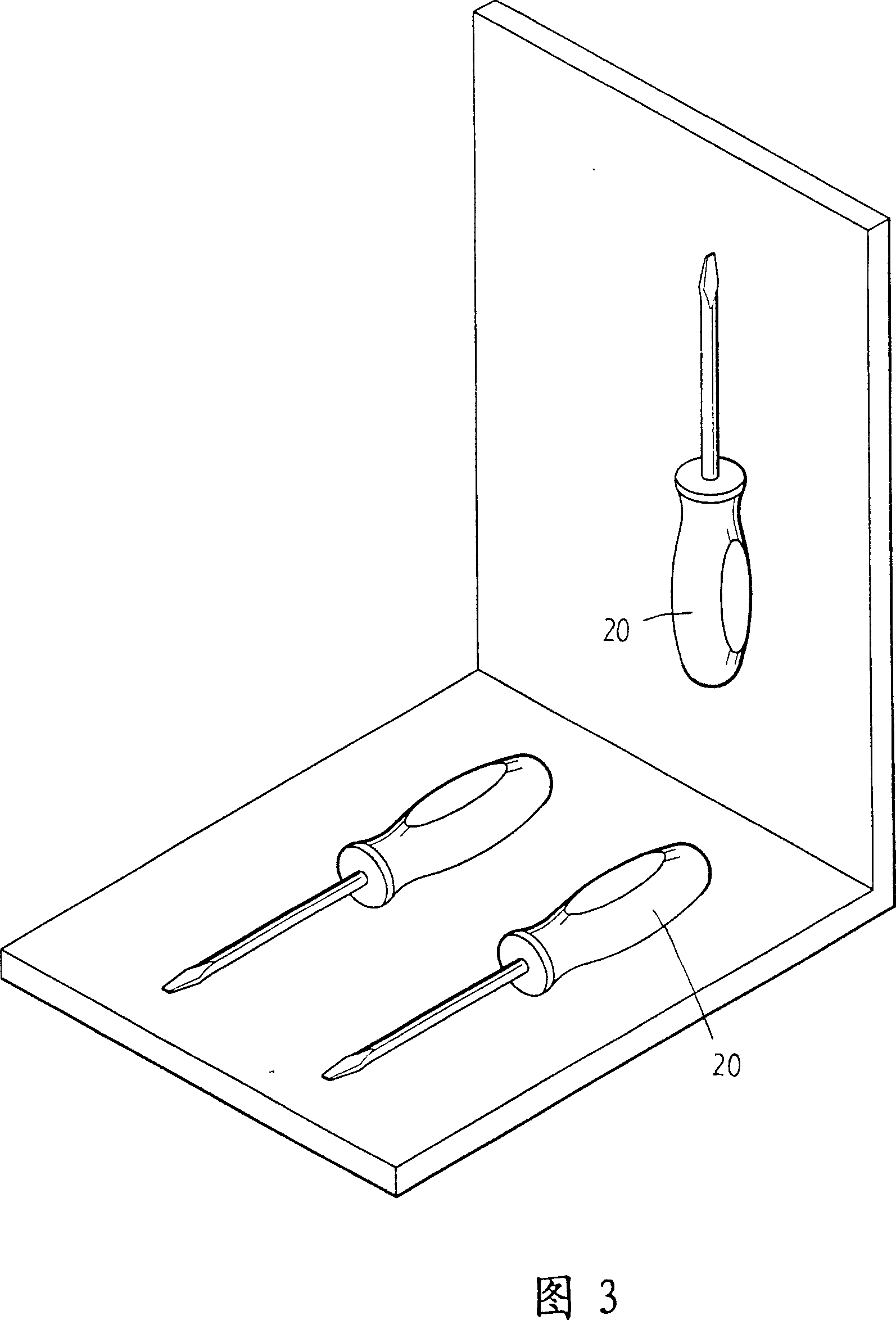

A manufacturing method and handle technology, which can be used in the manufacture of tools, wrenches, screwdrivers, etc., can solve problems such as inability to fully satisfy, easy to lose the function of adsorption, and limited efficacy, and achieve unique structural features and functions, cost-effective, and manufacturing. The effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific manufacturing method, steps, features and effects of the manufacturing method of the magnetic handle according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

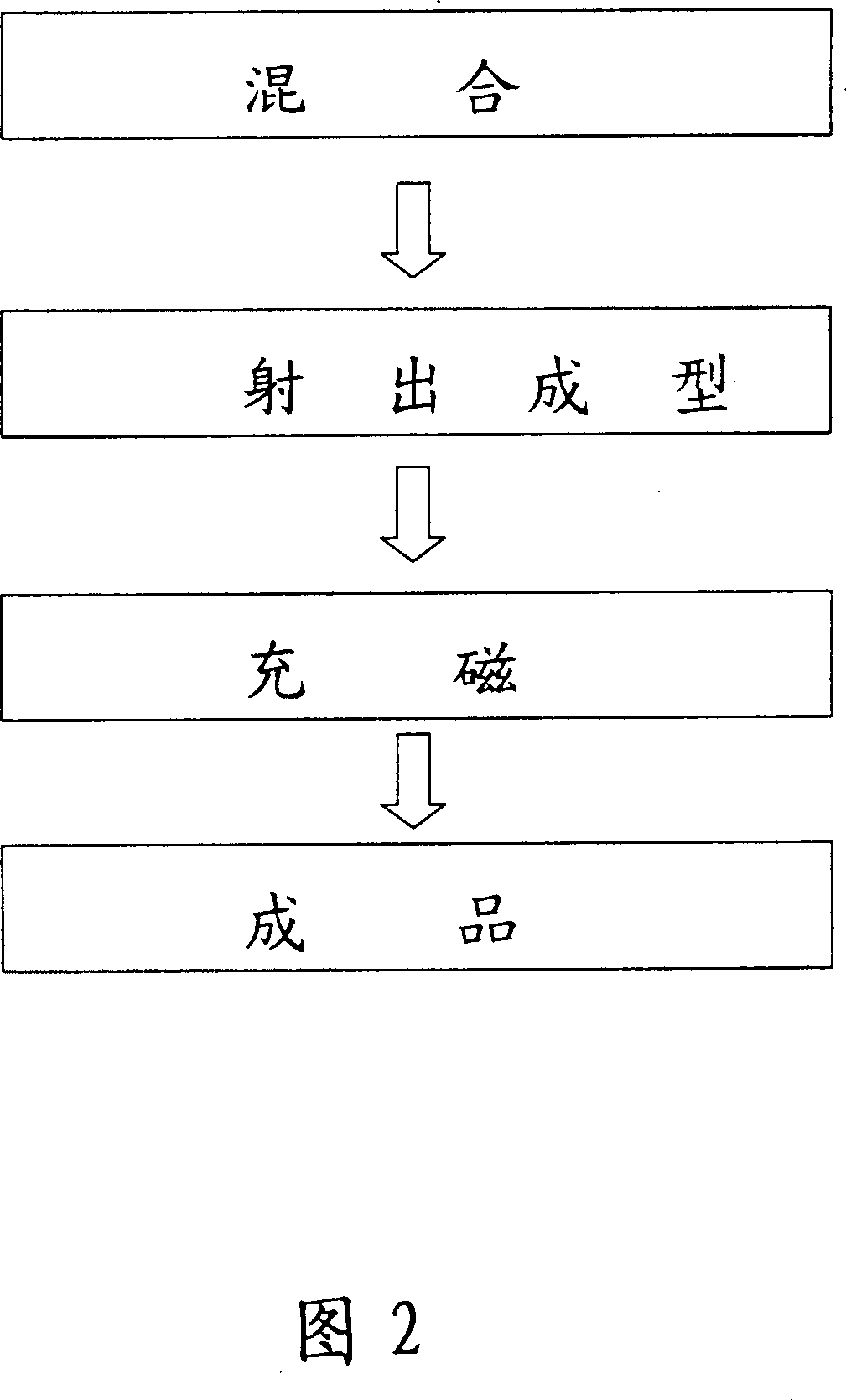

[0033] See also shown in Figure 2, the manufacturing method of the present invention can have magnetic handle, and it mainly comprises the following steps:

[0034] 1. Mixing: When using the plastic injection molding machine to inject the handle semi-finished product, it is necessary to mix the magnetic powder or magnetic block into the plastic molding material;

[0035] 2. Injection molding: Put the mixed magnetic powder or magnetic block material into the plastic injection molding machine, and inject the rough embryo of the handle;

[0036] 3. Magnetization: use the electrode to magnetize the rough embryo of the handle that has been injection molded to form a semi-finished handle;

[0037] 4. Finished product: trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com