Circulation type permanent magnetic stirrer

A permanent magnet agitator, circulating technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve the problems of small stirring range, short service life, uneven stirring, etc., and achieve simple and reliable transmission and long service life. , good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

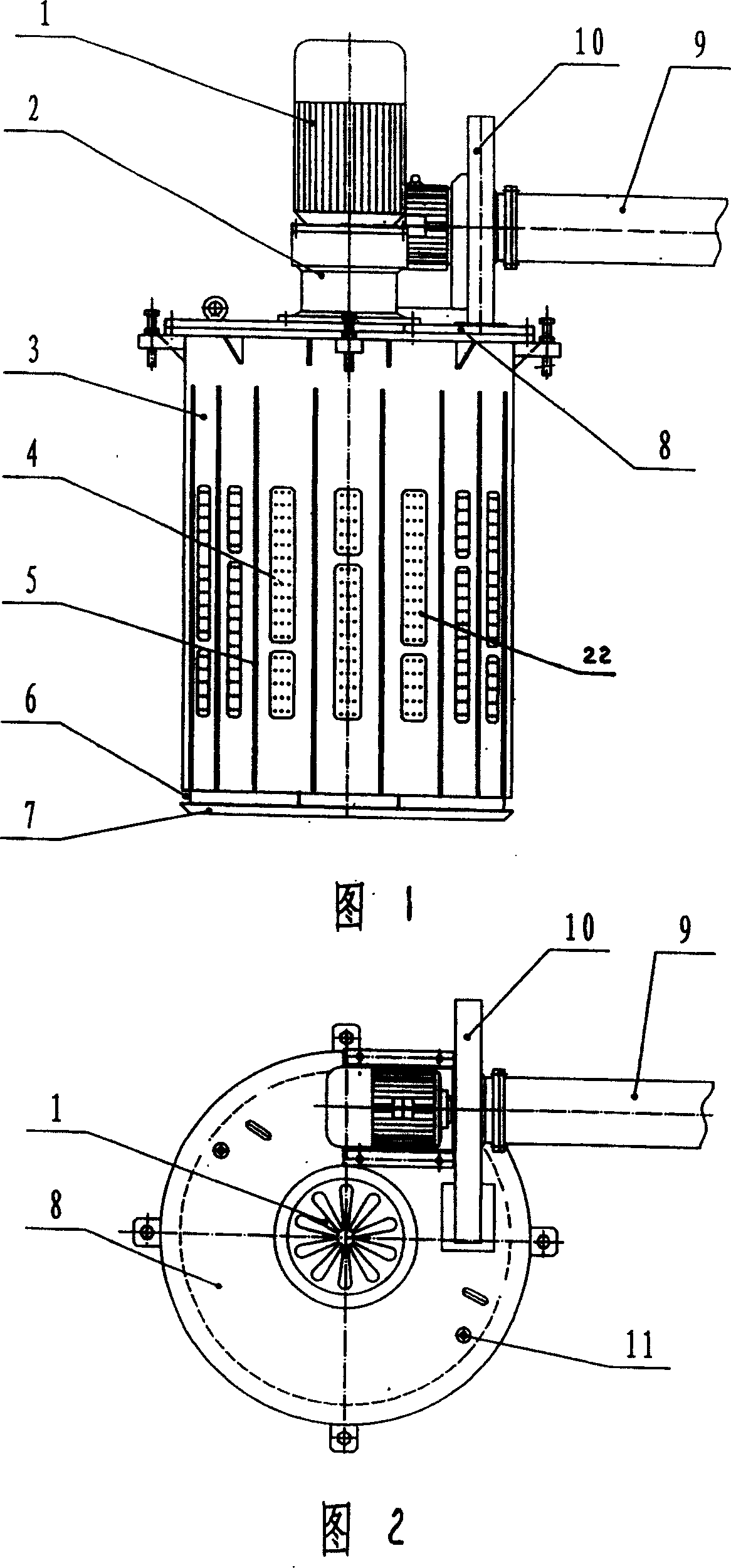

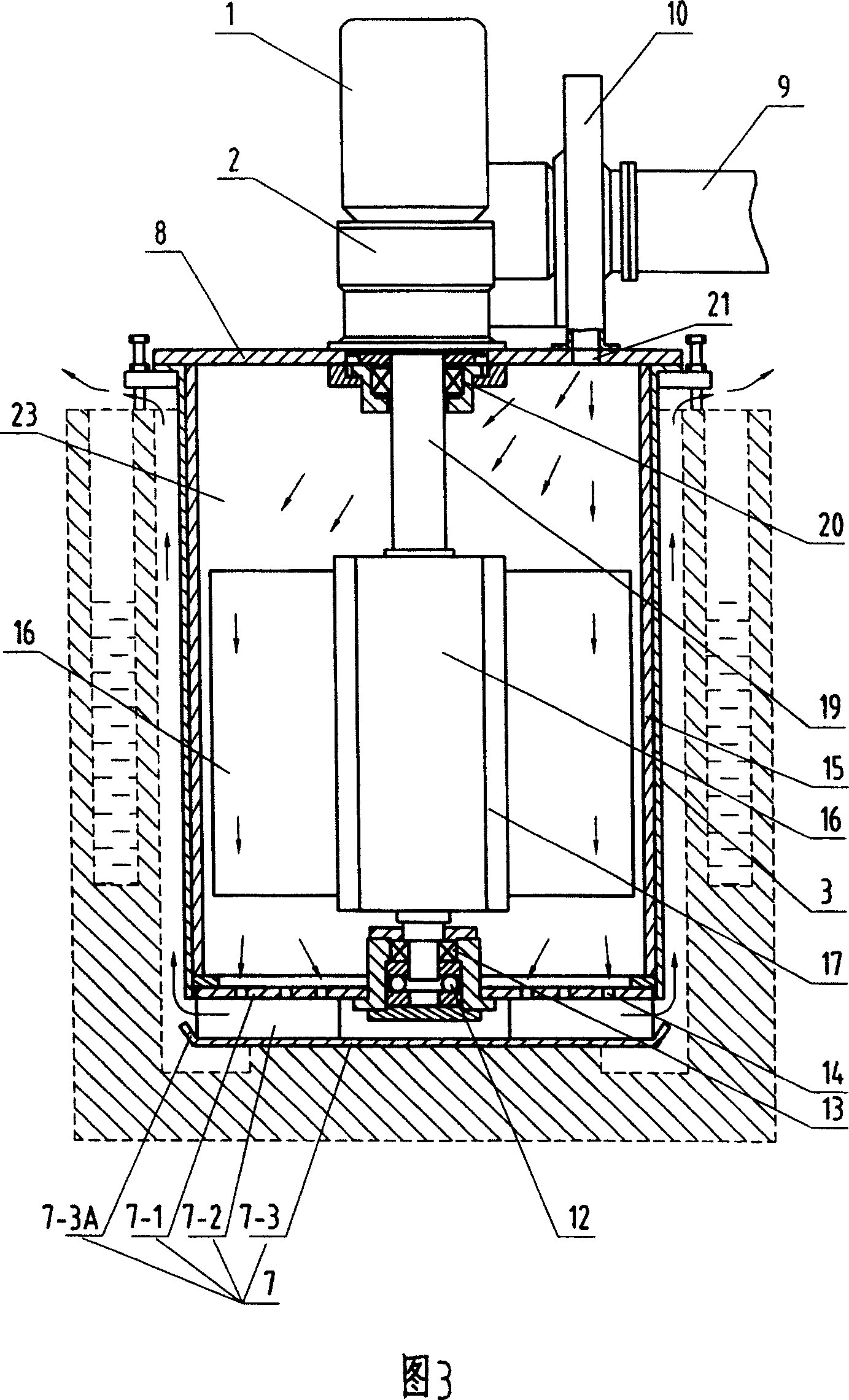

[0028] With reference to accompanying drawing, the circulating permanent magnetic stirrer described in the embodiment comprises chassis 7, the outer cover 3 that is made with non-magnetic material and is affixed with chassis 7, is coated with nonmetallic heat insulating layer 15 on the inner wall of outer cover 3 , the upper end of the outer cover 3 is fixedly connected with the upper end cover 8, and the inner cavity surrounded by the chassis 7, the outer cover 3 and the upper end cover 8 is the sensor cavity 23, which is installed on the chassis through the thrust ball bearing 12 and the cylindrical roller bearing 13. The rotating shaft 19 on the 7 and perpendicular to the chassis 7 protrudes through the inductor cavity 23 and the spherical roller bearing 20 on the upper end cover 8, and the motor 1 and the reducer 2 are directly shaft-coupled on the extending end of the rotating shaft 19, and the rotating shaft 19 is a solid shaft. On the upper end cover 8, a thermocouple 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com