Biological method for simultaneously removing SO2íóNOXíóheavy metal and granule from gas

A technology for heavy metals and particulate matter, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of simultaneous removal and high cost of pollutant treatment, and achieve the effect of improving the denitrification rate and realizing comprehensive treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

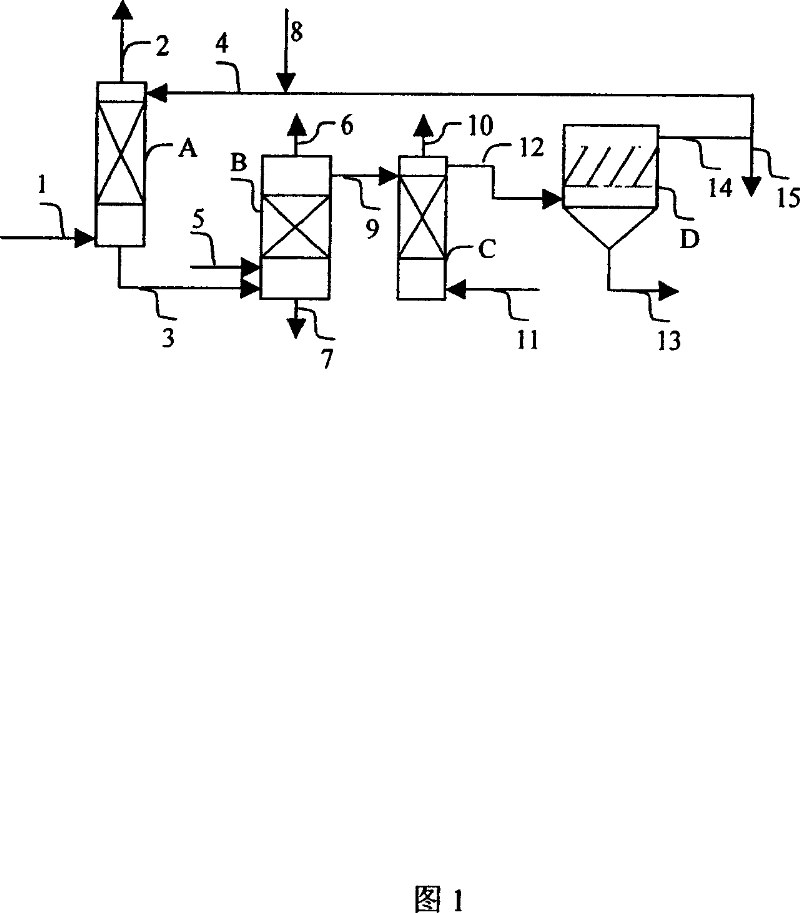

Image

Examples

Embodiment 1

[0038] 1) Set the temperature to 120°C, containing SO 2 (5000mg / m 3 ), NO x (500mg / m 3 ), Hg (20mg / m 3 ), dust (10000mg / m 3 ) of flue gas at 10m 3 The rate of / h is passed into the packed column, containing 10 9 cells / ml nitrifying bacteria, 10 8 cells / ml The biological absorption solution of sulfur oxidizing bacteria is sprayed from the top of the tower at a rate of 50l / h, and the gas discharged from the top of the tower contains SO 2 3 , NO x 3 , Hg3 , Dust3 ;

[0039] 2) The absorption liquid is passed into an anaerobic reactor containing sulfate-reducing bacteria and denitrifying bacteria. After 30 hours of treatment, the S in the liquid 4+ +S 6+ Concentration3+ +N 5+ Concentration <40mg / L, Hg concentration <0.1mg / L;

[0040] 3) The effluent from the anaerobic reactor enters the aerobic reactor, and after 2 hours of treatment, the effluent S 2- Less than 2mg / L, the content of elemental sulfur in solid particles in water is about 80%.

Embodiment 2

[0042] 1) Set the temperature at 20°C, containing SO 2 (1000mg / m 3 ), NO x (500mg / m 3 ), Zn (50mg / m 3 ) simulated exhaust gas at 10m 3 The rate of / h is passed into the packed column, containing 10 10 cells / ml nitrifying bacteria, 10 6 cells / ml The biological absorption solution of sulfur oxidizing bacteria is sprayed from the top of the tower at a rate of 5l / h, and the gas discharged from the top of the tower contains SO 2 3 , NO x 3 , Zn3 ;

[0043] 2) The absorption liquid is passed into an anaerobic reactor containing sulfate-reducing bacteria and denitrifying bacteria. After 5 hours of treatment, the S in the liquid 4+ +S 6+ Concentration3+ +N 5+ Concentration < 20mg / L, Zn concentration < 0.05mg / L;

[0044] 3) The effluent from the anaerobic reactor enters the aerobic reactor, and after 0.4h treatment, the effluent S 2- Less than 2mg / L, the content of elemental sulfur in solid particles in water is about 70%.

Embodiment 3

[0046] 1) Set the temperature to 150°C, containing SO 2 (3000mg / m 3 ), NO x (1000mg / m 3 ), Hg (50mg / m 3 ), dust (5000mg / m 3 ) simulated exhaust gas at 10m 3 The rate of / h is passed into the packed column, containing 10 11 cells / ml nitrifying bacteria, 10 7 cells / ml The biological absorption solution of sulfur oxidizing bacteria is sprayed from the top of the tower at a rate of 20l / h, and the gas discharged from the top of the tower contains SO 2 3 , NO x 3 , Hg3 , Dust3 ;

[0047] 2) The absorption liquid is passed into an anaerobic reactor containing sulfate-reducing bacteria and denitrifying bacteria. After 20 hours of treatment, the S in the liquid 4+ +S 6+ Concentration3+ +N 5+ Concentration <50mg / L, Hg concentration <0.05mg / L;

[0048] 3) The effluent from the anaerobic reactor enters the aerobic reactor, and after 1.0 hours of treatment, the effluent S 2- Less than 3mg / L, the content of elemental sulfur in solid particles in water is about 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com