Processing method of wooden shutter vanes

A processing method and louver technology, which is applied in the processing field of wood products, can solve the problems of three-dimensional decorative paper waste, hazards, and increased cost of processing blades, and achieve the effects of avoiding unreasonable waste, improving the working environment, and eliminating paint fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

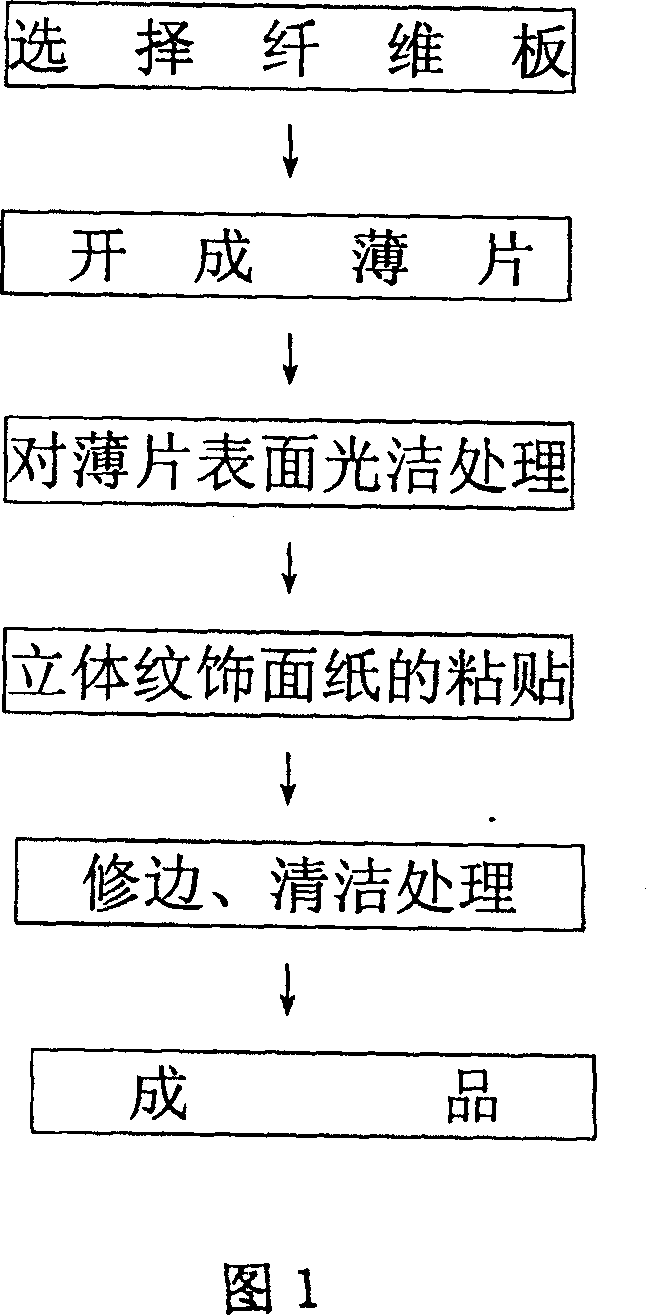

[0022] Obtain the wooden venetian blind blade product shown in Figure 2 through the process steps shown in Figure 1 .

[0023] a) Purchase medium-density boards with a length of 2400mm, a width of 1200mm, and a thickness of 3mm or high-density boards with a thickness of 2.5mm from commercial channels, and cut them into lengths of 1200mm, Sheet 1 with a width of 50 mm, so that 48 sheets with a thickness of 3 mm or 48 sheets with a thickness of 2.5 mm can be obtained;

[0024] b) Perform a smooth treatment on all surfaces of the sheet 1, specifically, sand the front, back, left and right sides of the sheet 1 or polish with corresponding equipment, and remove the dust remaining on all surfaces of the sheet 1. Sand the surface or polish it with corresponding equipment, and remove the dust remaining on all surfaces of the sheet 1;

[0025] c) The waterproof and wear-resistant layer 3 obtained by coating the surface with unsaturated resin or spraying aluminum oxide particles on the...

Embodiment 2

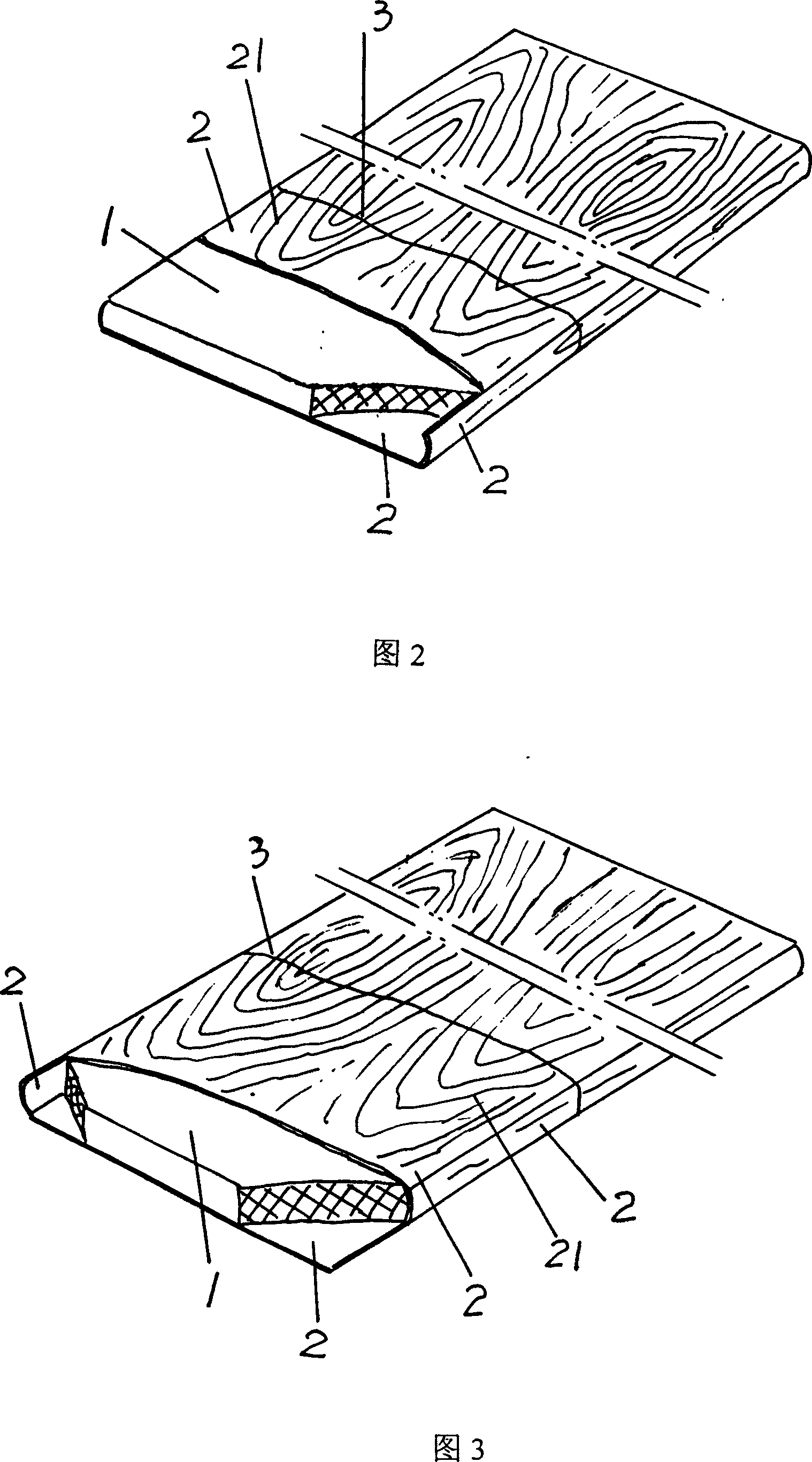

[0028] Obtain the wooden venetian blind blade product shown in FIG. 3 through the process steps shown in FIG. 1 .

[0029] Only change the thickness of the medium and high-density boards in step a) to 6mm and 5mm respectively and change step c) encapsulation and pasting to change the three-dimensional grain decorative paper 2 with wood texture 21 from the lower surface of the sheet 1 to the sheet 1 The front side further extends to the upper surface of the sheet 1 and then extends to the rear side of the sheet 1 to form a wooden wooden board as shown in Figure 3 that is integrally encapsulated with three-dimensional pattern decorative paper 2 on four sides, that is, the upper and lower surfaces and the front and rear sides. Venetian blind blade finished product, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com