Application of natural silica material in making transparent rock and transparent rock mass

A silica and natural technology, applied in the field of civil engineering visualization model test, can solve the problems of material property differences and achieve stable properties, good optical properties, and high similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

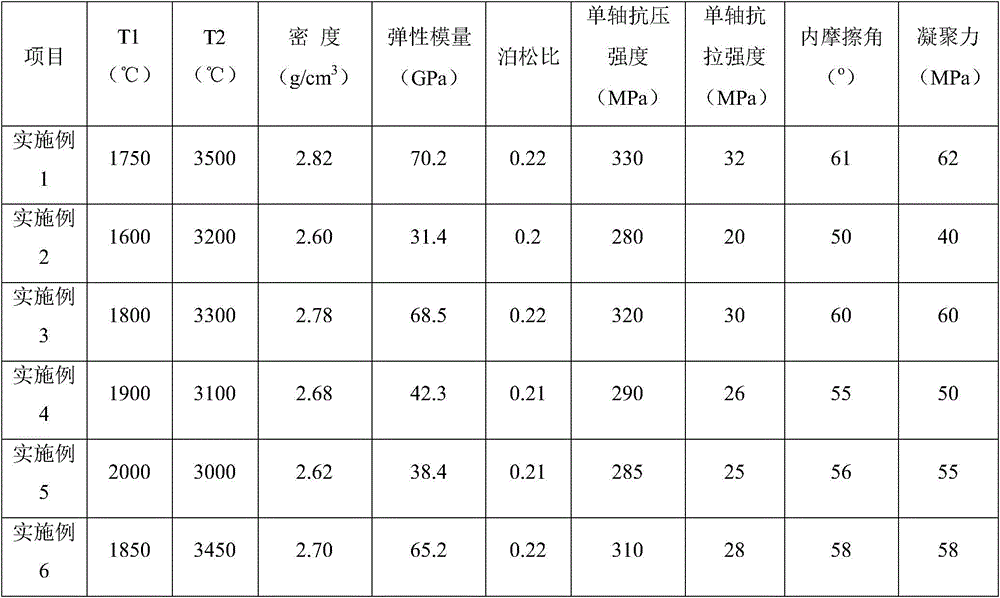

Examples

Embodiment 1

[0042] Example 1 Preparation of transparent rock.

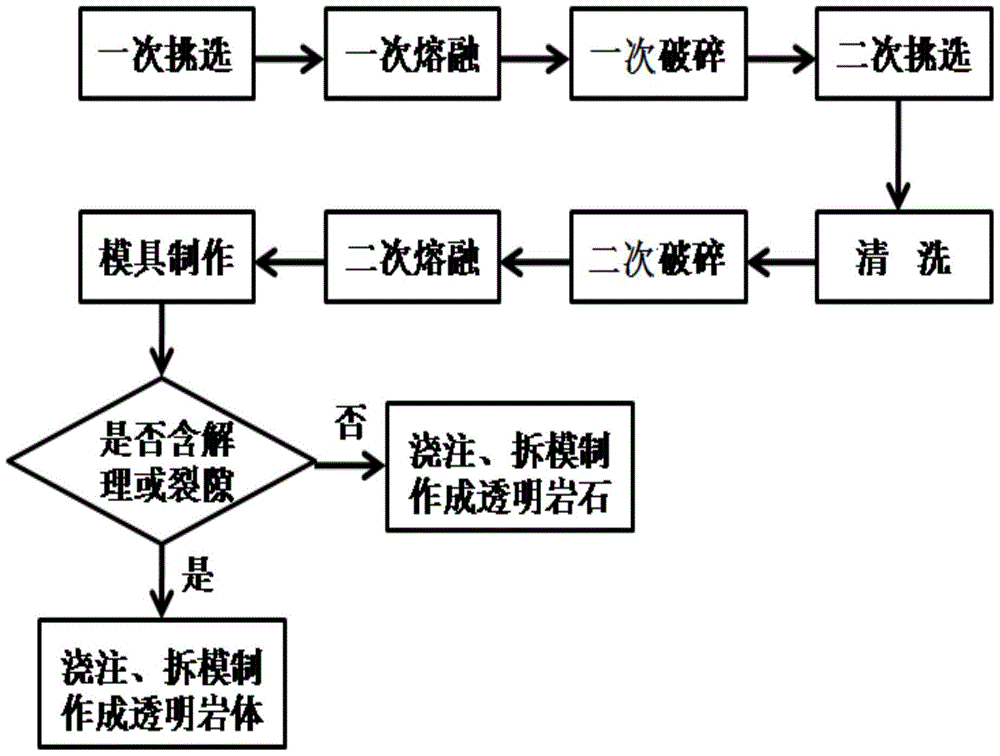

[0043] A kind of method that utilizes natural silica raw material to make transparent rock that the present invention proposes comprises the following steps:

[0044] (1) Material selection: Take the natural silica material block, clean the surface stains of the natural silica material, and remove the natural silica material block with high impurity content according to visual inspection. The particle size of the natural silica material varies, and appropriate manual crushing can be carried out Filling and removing parts with high impurities;

[0045] (2) Primary melting: Primary melting is realized in the first boiler. The first boiler of this embodiment is a cylinder with a height of 2m, an inner diameter of 2m, and a height of 2m, with a volume of about 6.3m 3 , in the middle of the first boiler, an activated carbon rod capable of absorbing impurities is arranged, and activated alumina is arranged around to absorb impuri...

Embodiment 7

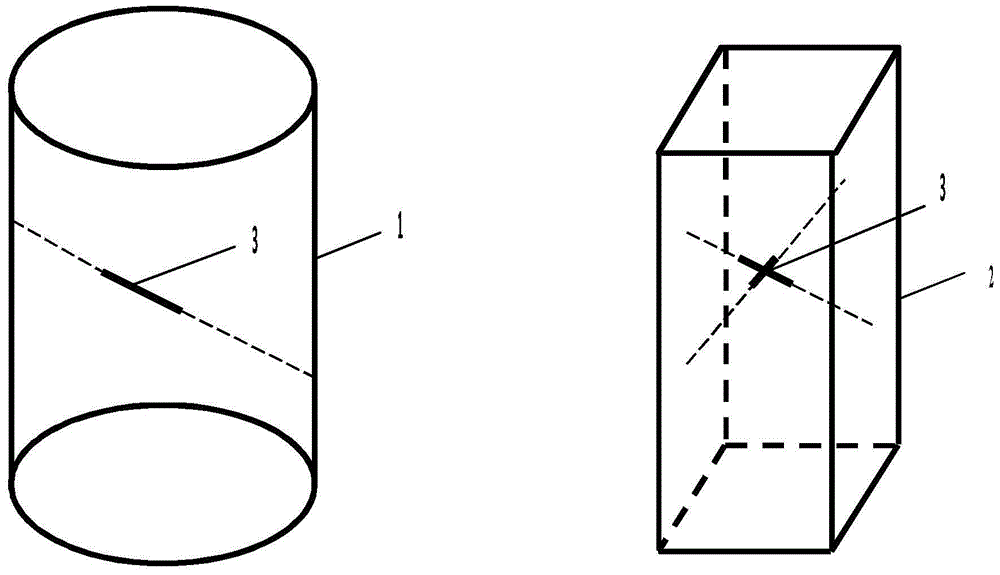

[0059] Example 7 Preparation of transparent rock mass.

[0060] The preparation steps are the same as in Example 1, the difference is that in step (8) mold making, the ceramic cloth is arranged inside the mold according to the design position, the ceramic cloth is 25mm long, 10mm wide, and 1mm thick, and the angle between the long side direction of the ceramic cloth and the horizontal is 45° distribution.

Embodiment 8

[0061] Example 8 Preparation of transparent rock mass.

[0062] The preparation steps are the same as in Example 1. The difference is that in step (8) mold making, colored and flaky quartz are arranged inside the mold according to the design position. The quartz is 20mm long, 12mm wide, and 2mm thick. Colored, flaky quartz The distribution angle with the horizontal is 35°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com