LCD micromotion exposure and development device

A technology of micro-motion and micro-motion stage, which is applied in the field of digital imaging, can solve the problems of low LCOS yield rate, difficulty in industrialization, and insufficient stability of technology, so as to ensure high stability and repeatability, reduce complexity and Price, high color vibrancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

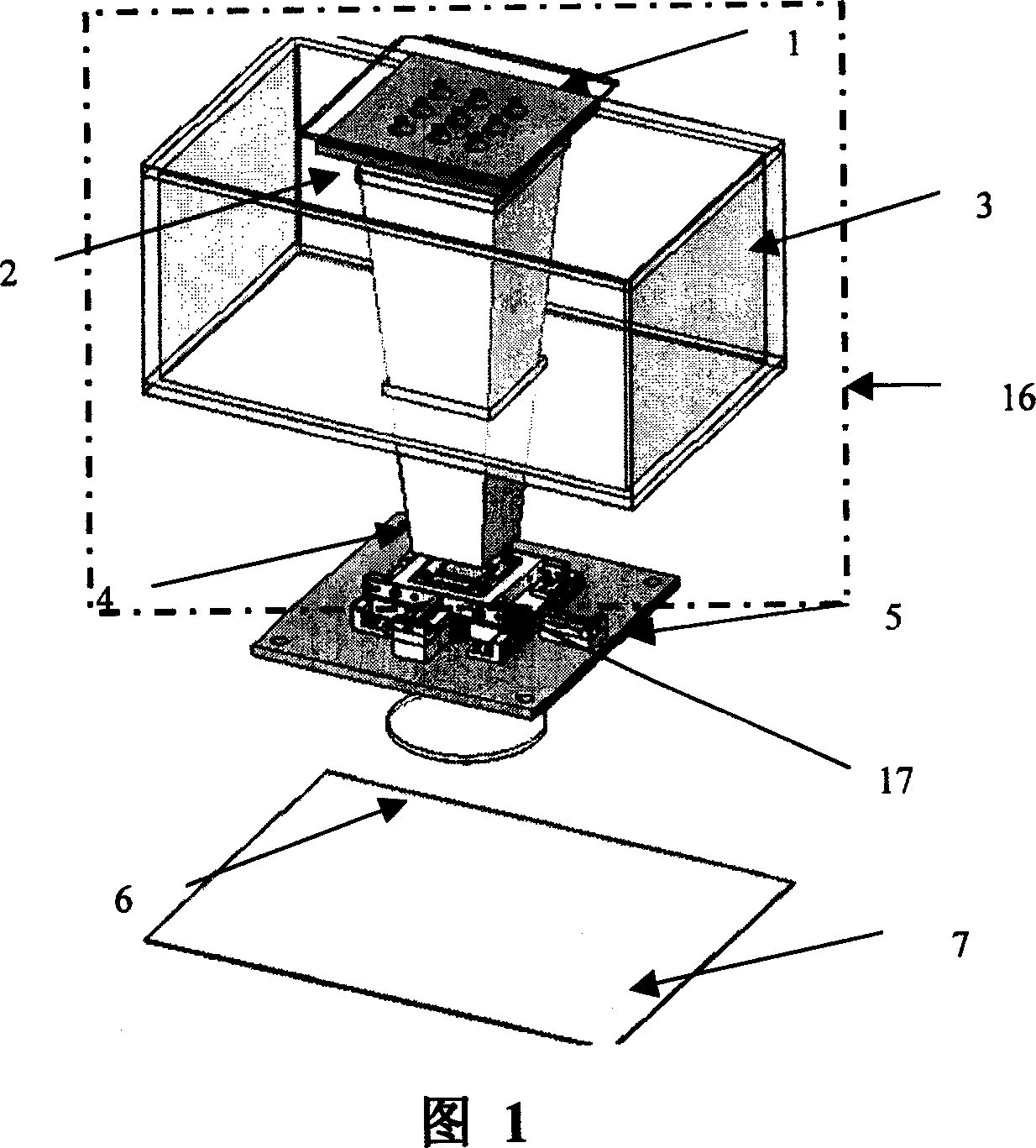

[0021] FIG. 1 is a schematic diagram of the structural composition of an embodiment of the micro-movement exposure device of the present invention. Within the scope of the dotted line in the figure is the multi-light source LED lighting system 16 of the present invention, which is composed of LED substrate 1, collimation frame 2, light mixing tube 4, and frosted glass 17 arranged on the same optical axis in sequence, and is fixed on the LED substrate 1. A group of red, green and blue three-color light-emitting diodes, a group of collimating mirrors are fixed on the collimation frame 2, and the outer surface of the light mixing tube 3 is embedded in the outer surface of the light mixing tube 4, which is used to fix the light mixing tube 3 and ensure the above part of the coaxial relationship. A collimation frame 2 is set close to the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com