Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Non-destructive creativity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

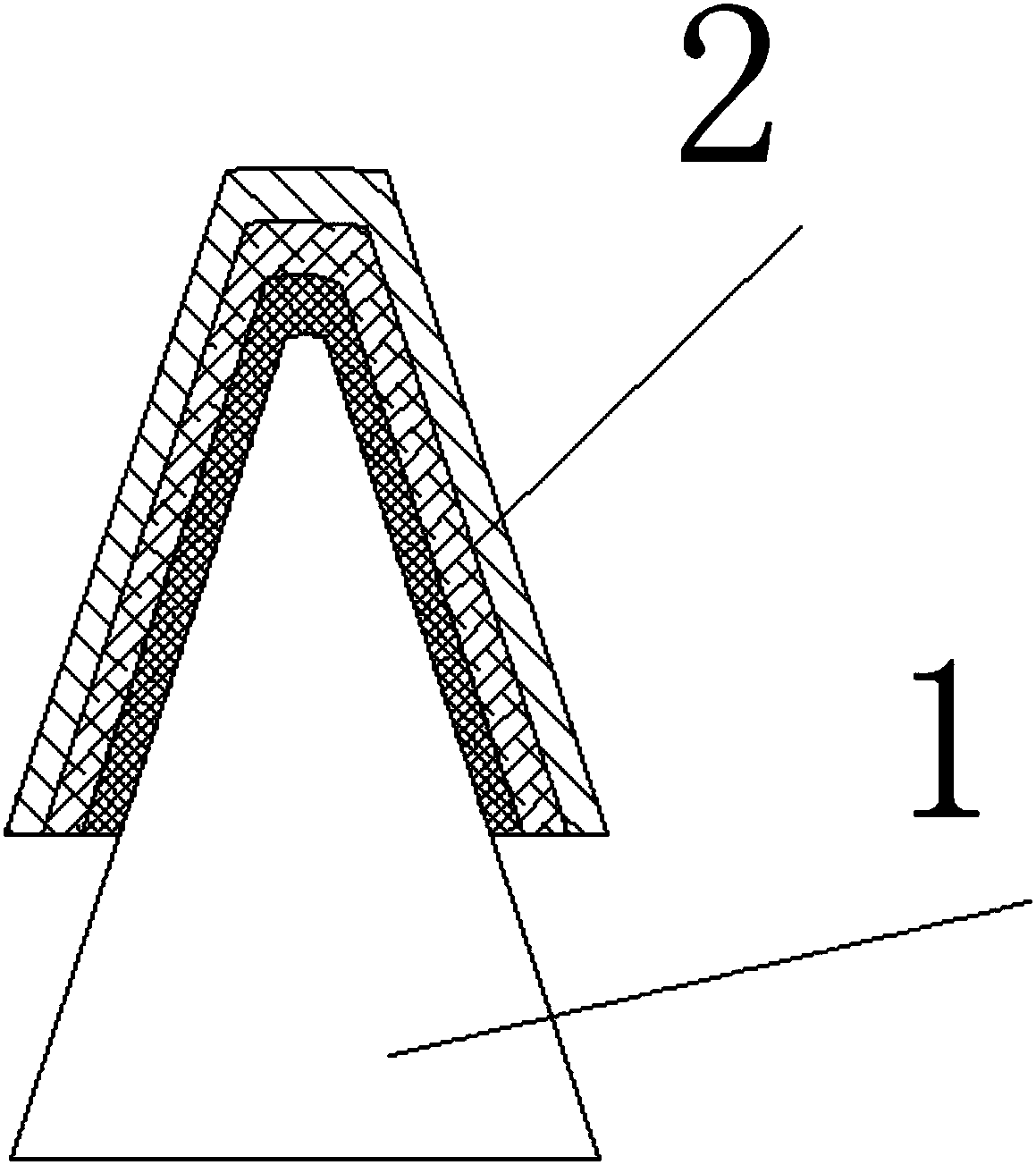

Method for making sharp composite particles for improving fracture healing

InactiveCN107822744ANon-destructive creativityBone implantJoint implantsAbsorbent materialFracture line

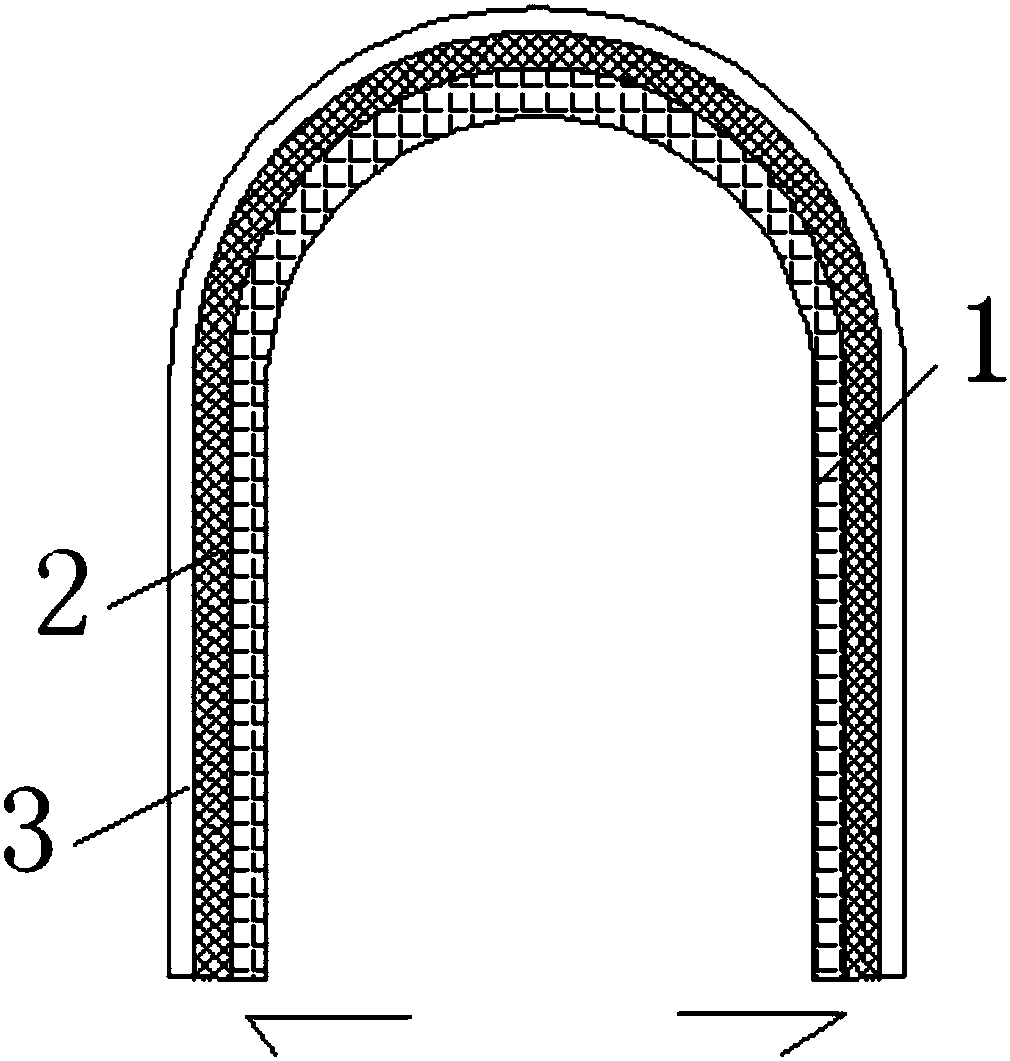

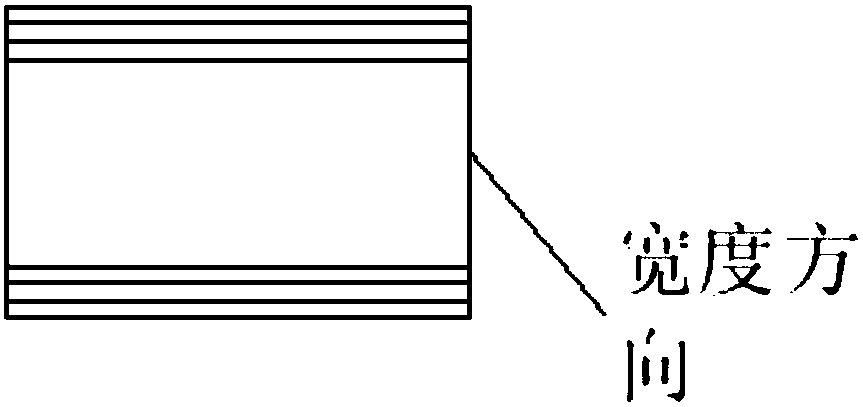

The invention provides a method for making pointed composite particles for improving fracture healing, which includes the following steps: 1) making a model whose apex section is "U"-shaped and consistent with the fracture line section; 2) making wet elastic layer, drug layer, the elastic layer is a dense degradable or non-degradable biofilm, the material of the drug layer is a degradable or non-degradable, absorbable or non-absorbable or porous material that is biocompatible with human bone, and the drug The inside of the layer is also encapsulated with drugs that can promote bone healing; 3) Cover the wet elastic layer on the top corner of the model, wrap the top corner of the model and extend to both sides of the top corner of the model, and then apply the wet drug layer Cover the elastic layer to form a biological microstructure film; 4) Cut the biological microstructure film in the width direction as required; 5) After the composite particles are air-dried and the shape is fixed, peel the prepared composite particles from the top corner of the model .

Owner:锡山区东港晓鸣电子产品经营部

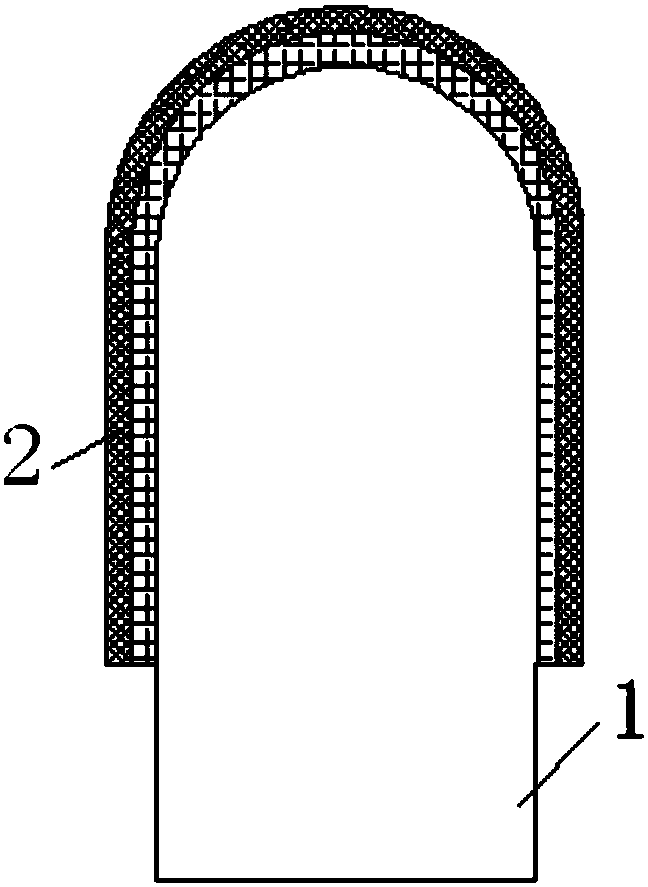

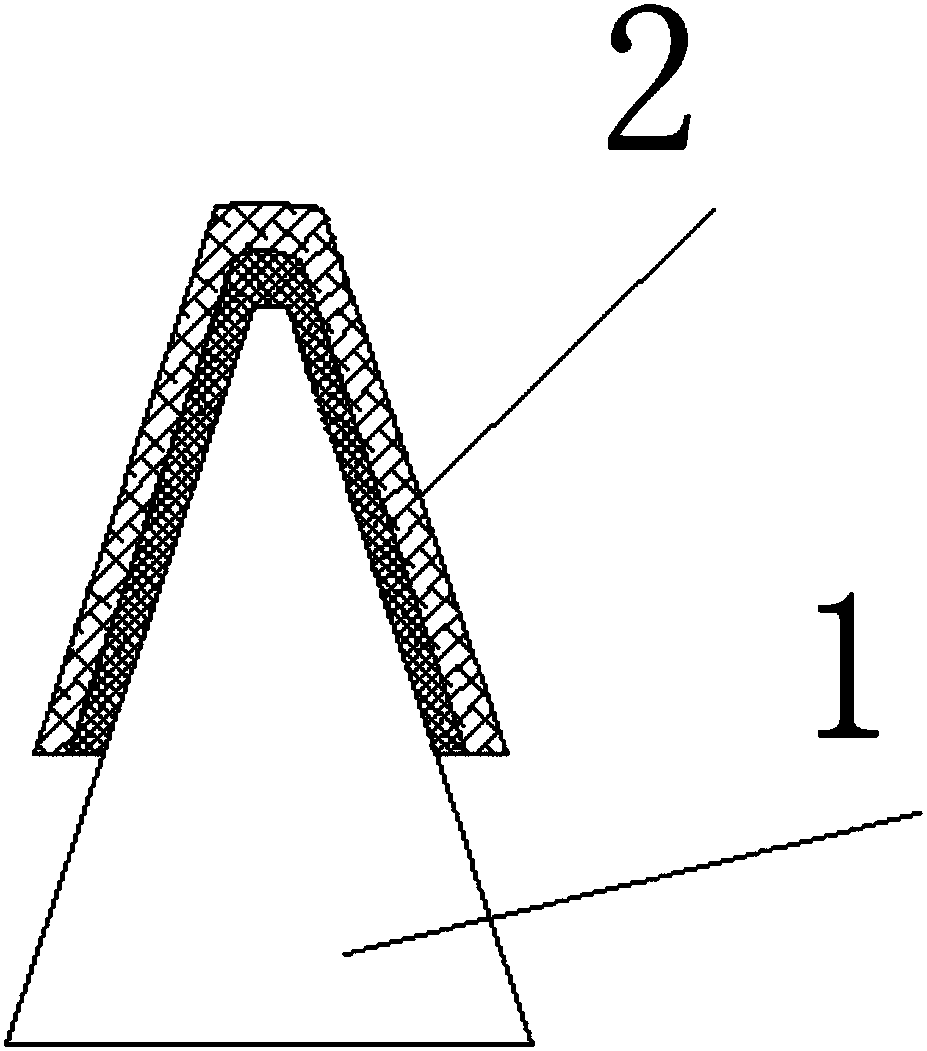

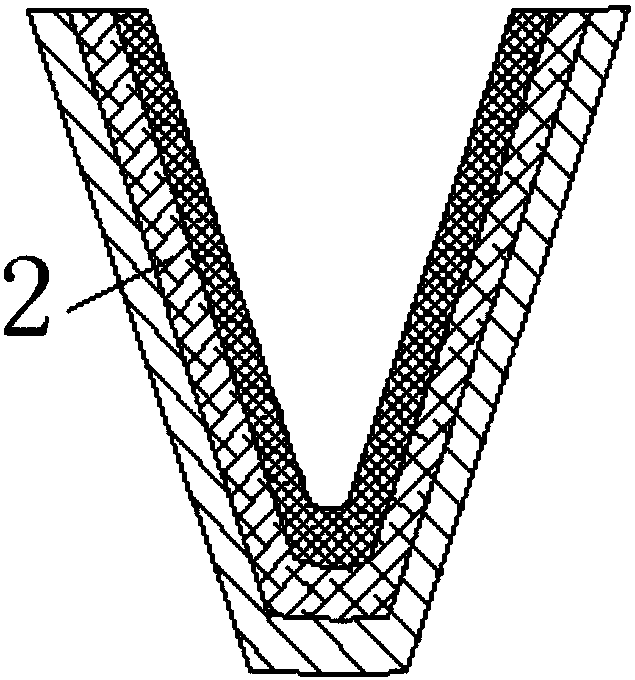

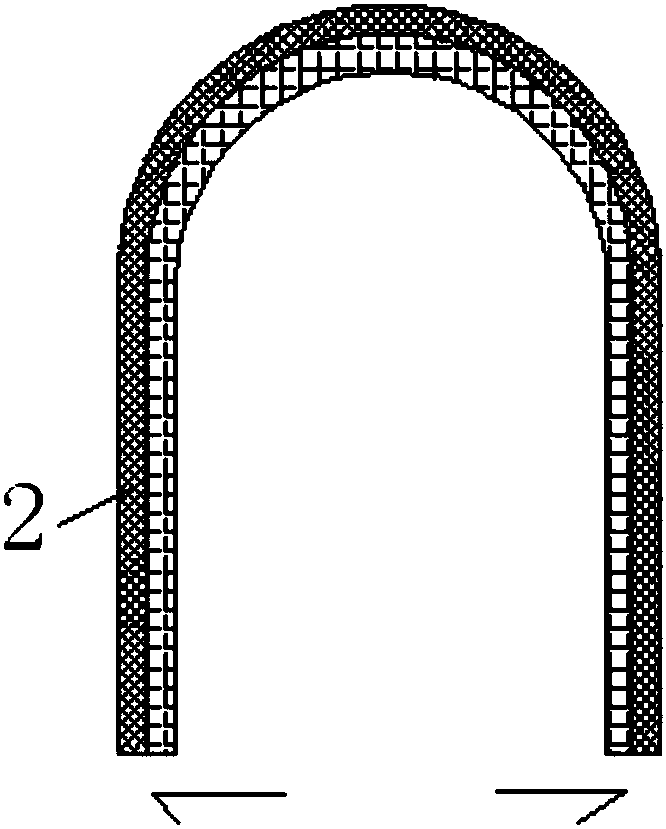

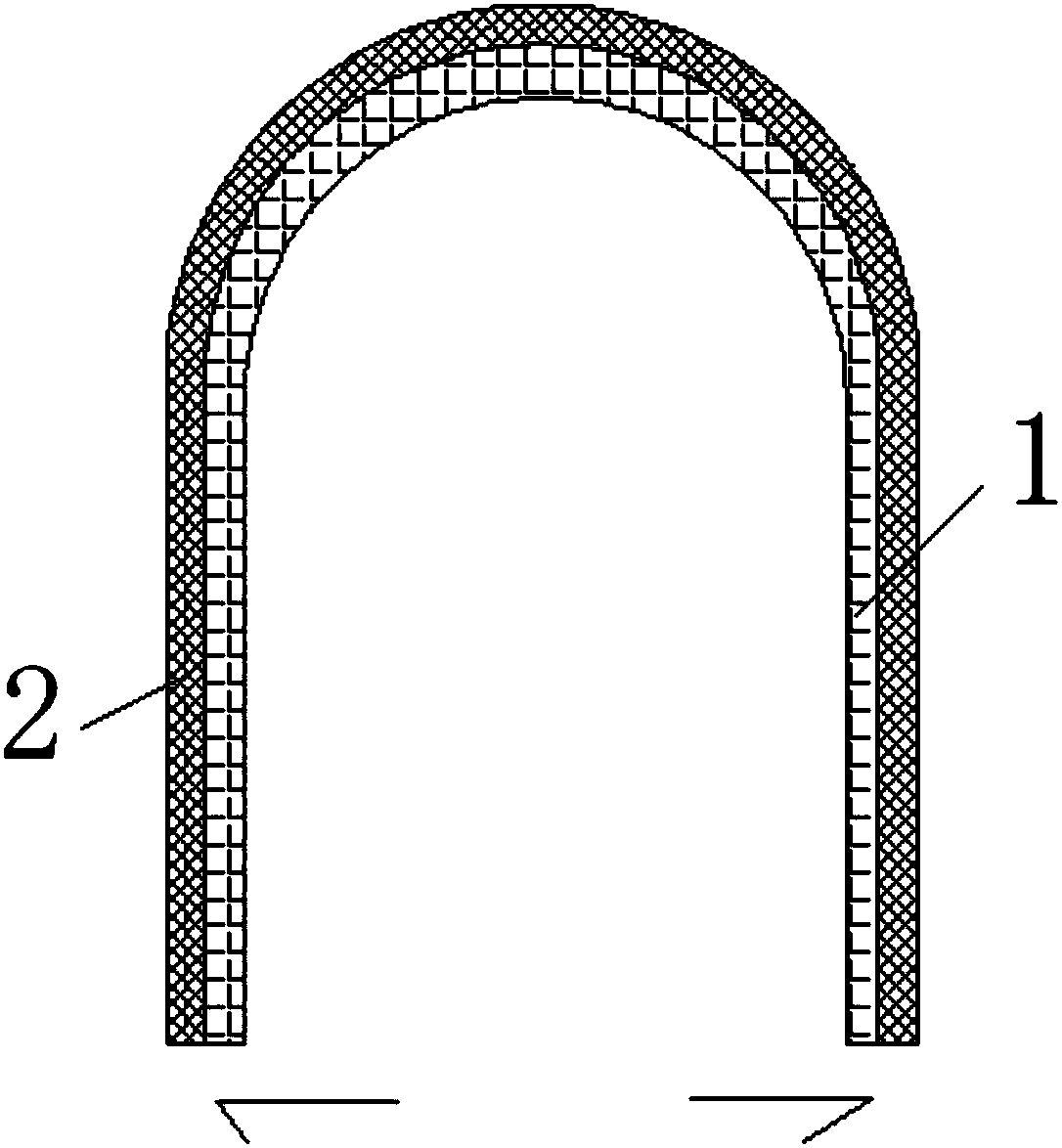

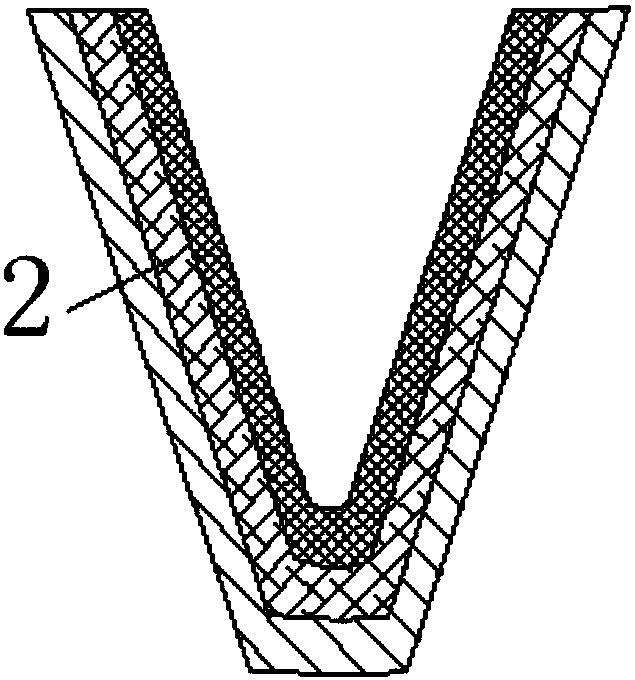

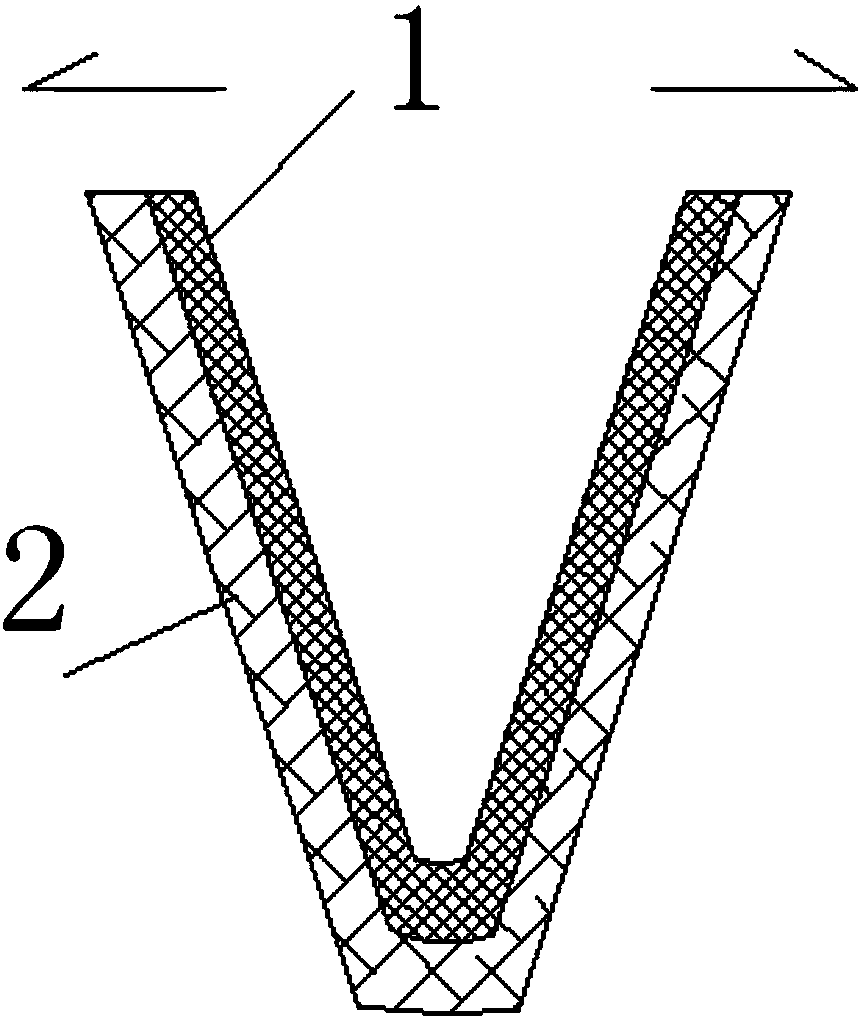

Sharp type biological film capable of improving fracture healing

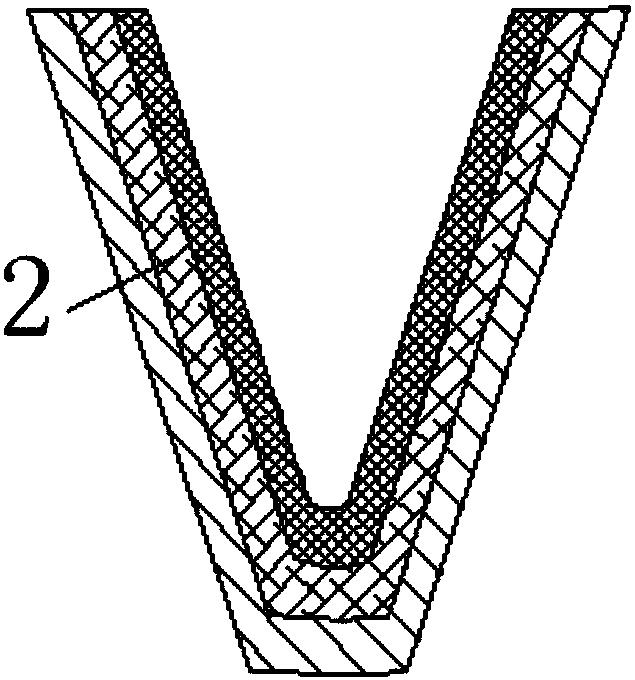

InactiveCN107625561ANon-destructive creativitySurgeryMedical devicesMicro structureBiocompatibility Testing

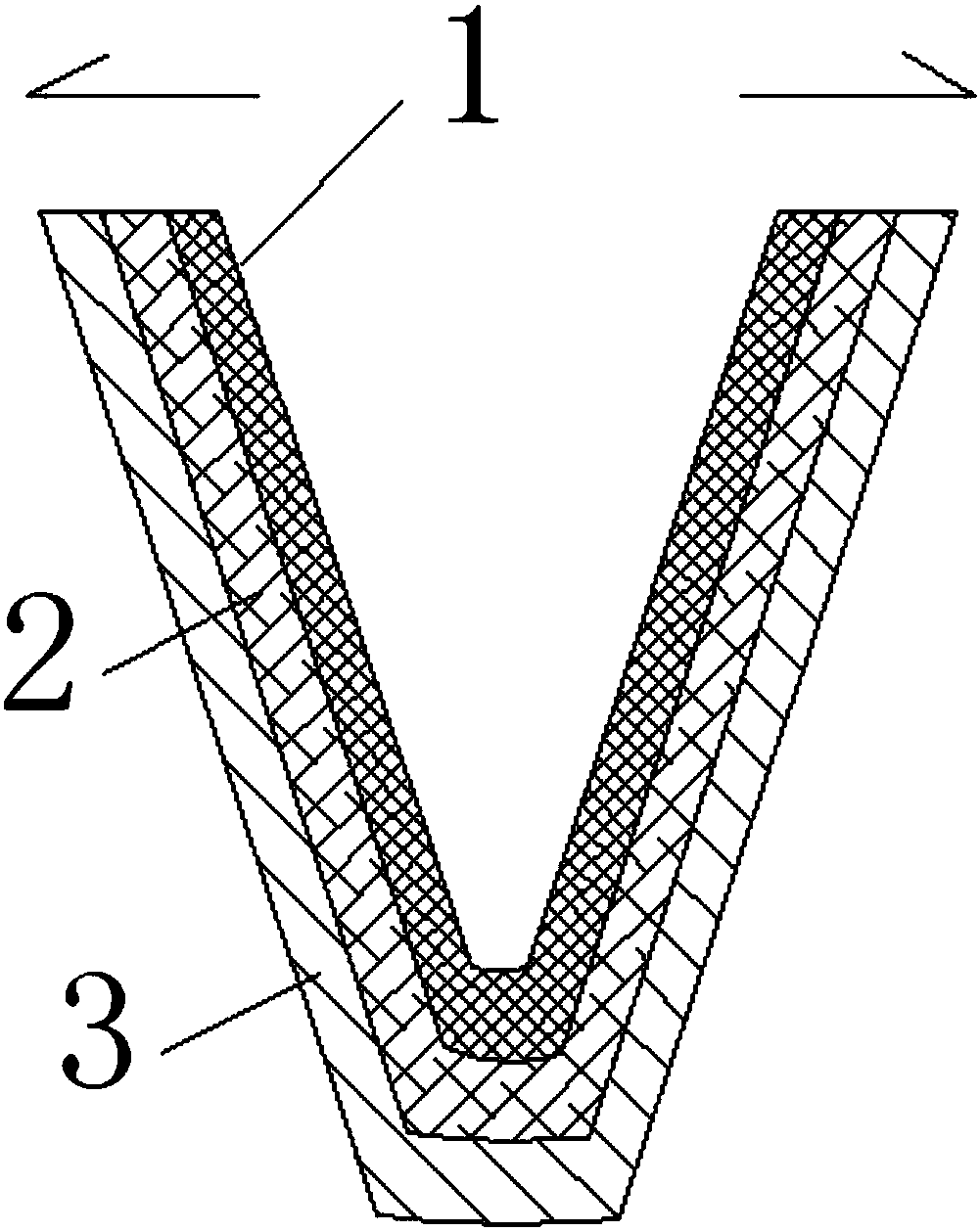

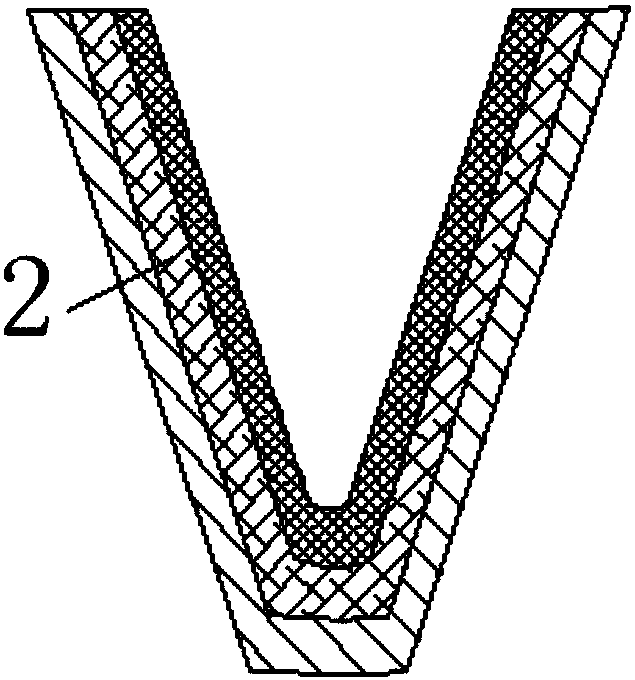

The invention provides a sharp type biological film capable of improving fracture healing. The sharp type biological film comprises an elastic layer and a medicine layer from inside to outside, wherein the elastic layer is a dense and degradable or absorbable biological film; the medicine layer is a porous loose material which has good biocompatibility with bones of human bodies, is degradable ornon-degradable and is absorbable or non-absorbable; a medicine which has a promotion effect on the fracture healing is also packaged in the medicine layer; a biological micro-structure film is of a long-strip-shaped folding structure and the section of the biological micro-structure film is V-shaped; an elastic layer is arranged in the biological micro-structure film and the medicine layer is arranged outside the biological micro-structure film; the ratio of the width to the depth of the V-shaped section is 0.5 to 1.5 and the width of the V-shaped section is a gap between surfaces of fracturedbones which are spliced together after a fracture surgery.

Owner:锡山区东港全宝机械经营部

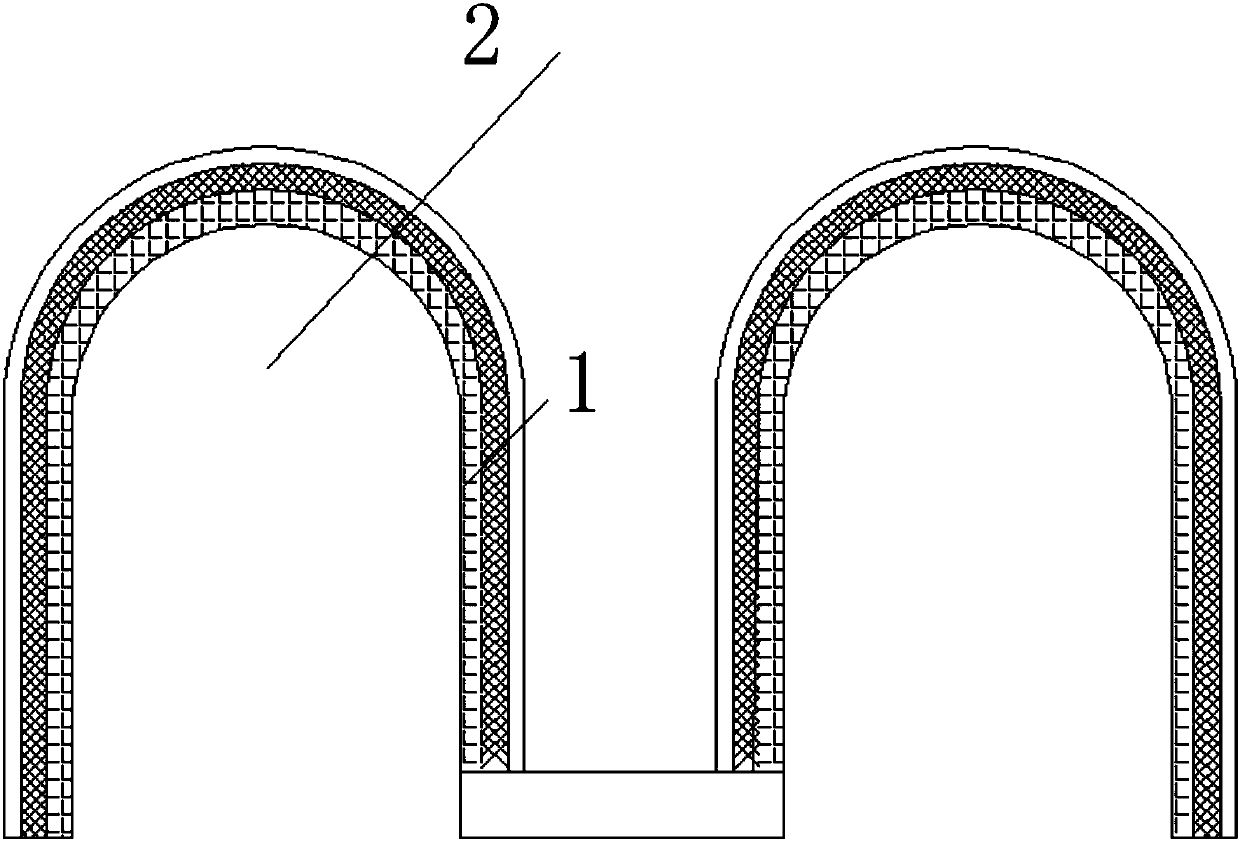

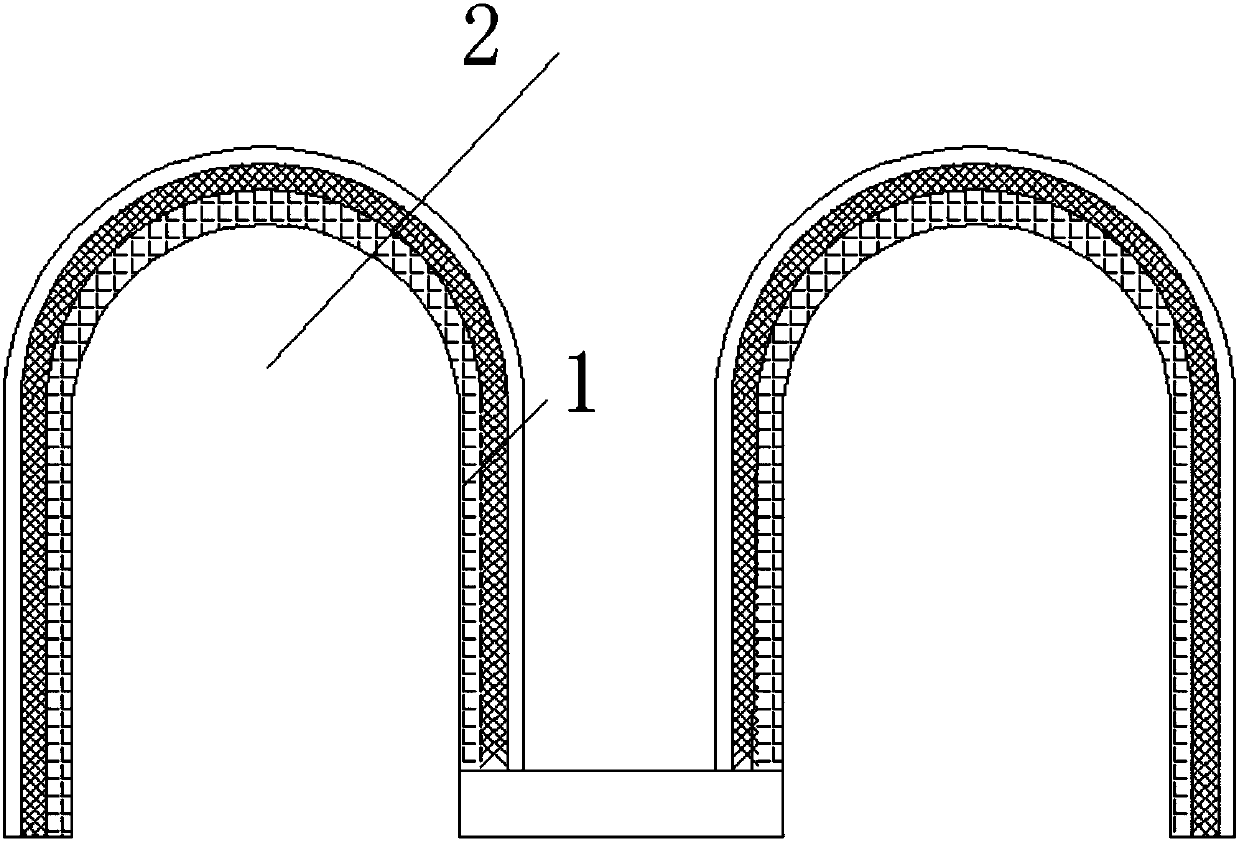

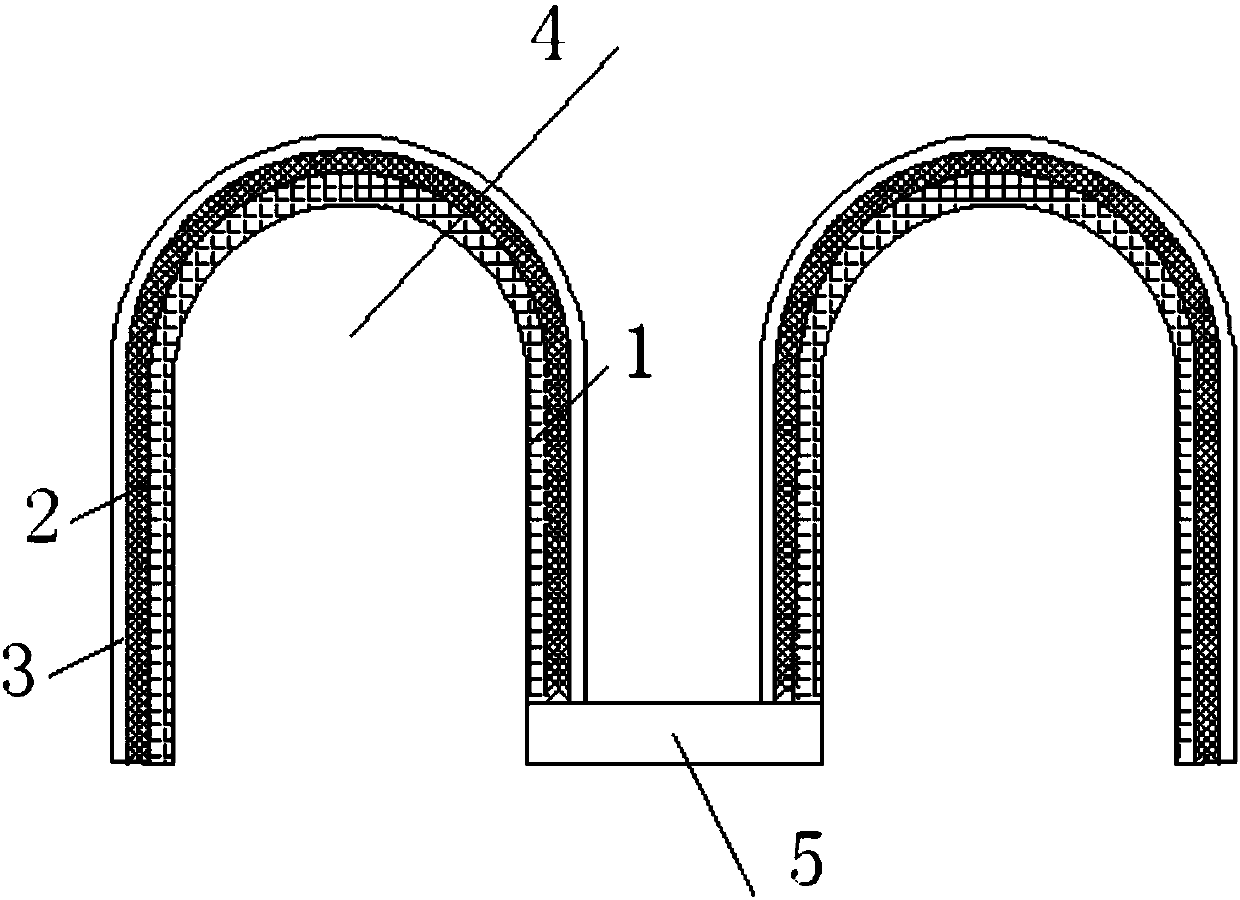

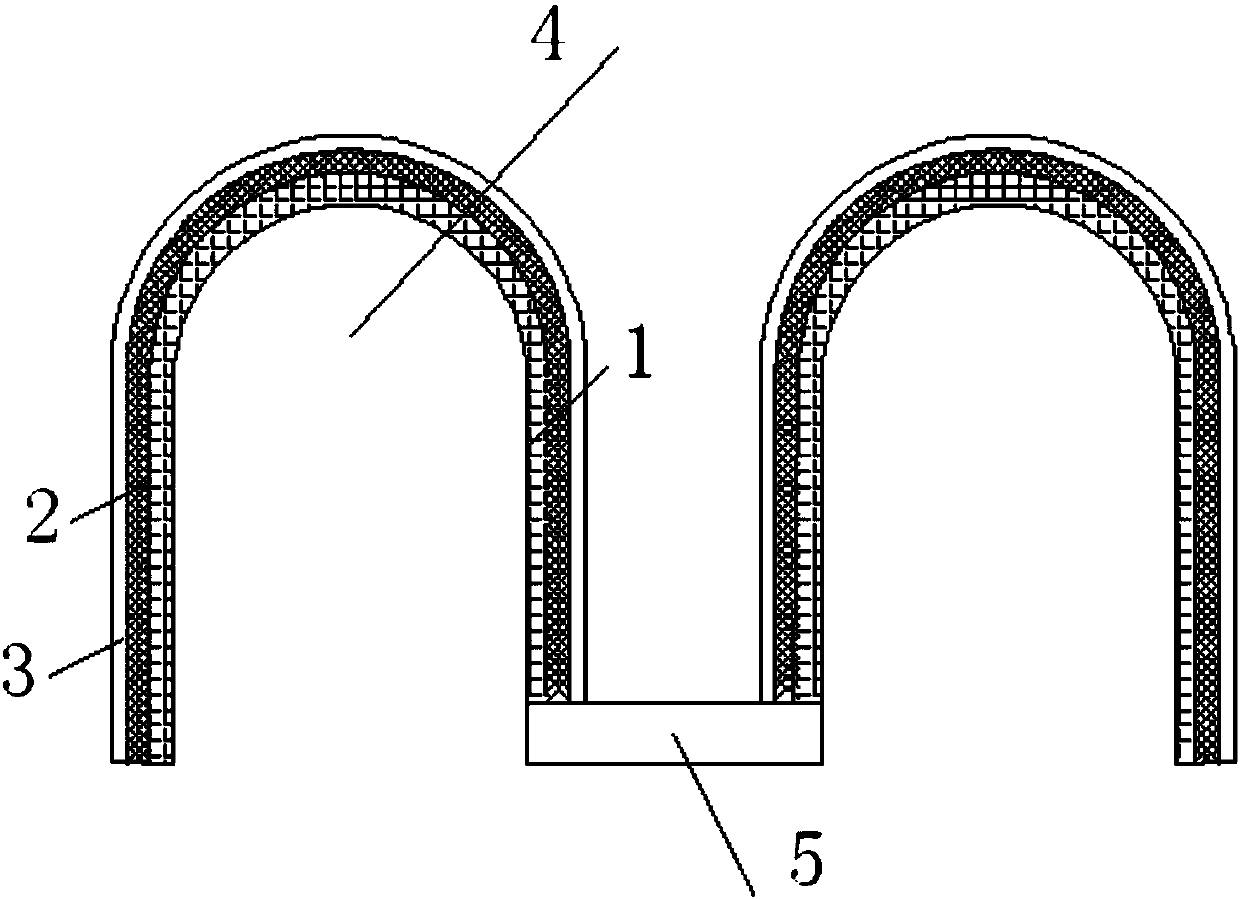

Manufacturing method of circular biofilm model array

The invention provides a manufacturing method of a circular biofilm model array. The method comprises that follow steps: 1) models which have U-shaped vertex cross sections and are matched with the fracture line cross section are manufactured in advance, the U-shaped models get close to each other to form the array, and bottoms of the adjacent U-shaped models are at an interval of 3-5 mm; 2) a wetelastic layer and medicine layer are manufactured respectively, wherein the elastic layer is a dense degradable or non-degradable biofilm, the medicine layer is made of a porous loose material whichis good in biocompatibility with human bone and is degradable or non-degradable and absorbent or non-absorbent, and a medicine with a bone healing promoting effect is also encapsulated in the medicinelayer; 3) the model array is covered with the wet elastic layer, the wet elastic layer wraps vertexes of the models in the array and extends to the periphery of the model array, the wet medicine layer then covers the elastic layer in the same range, and the biological microstructure film is formed; 4) after the biological microstructure film is air-dried and fixed in shape, the biofilm is cut offalong the edge of the corresponding U-shaped model, and the manufactured single biological microstructure film is stripped from the corresponding model.

Owner:锡山区东港玉英家电经营部

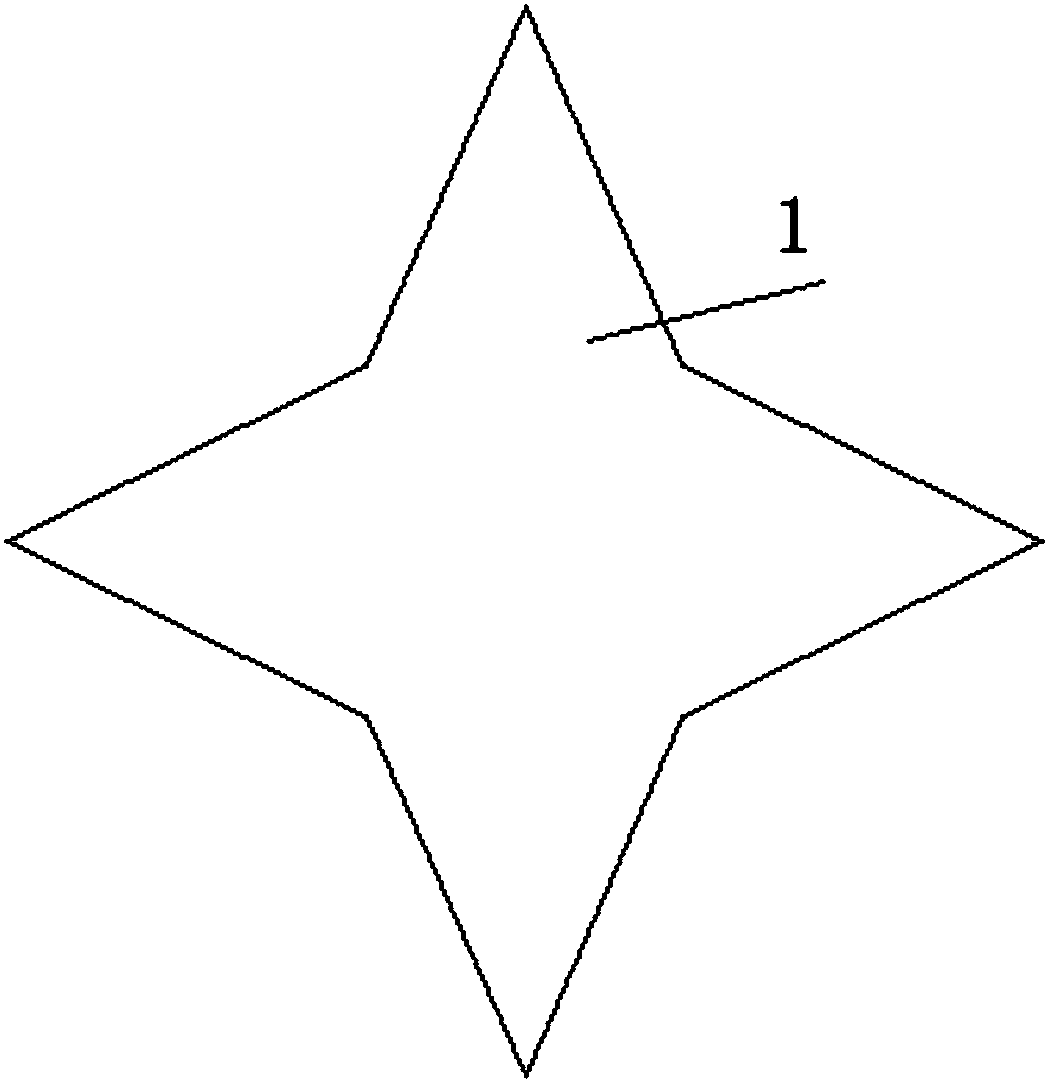

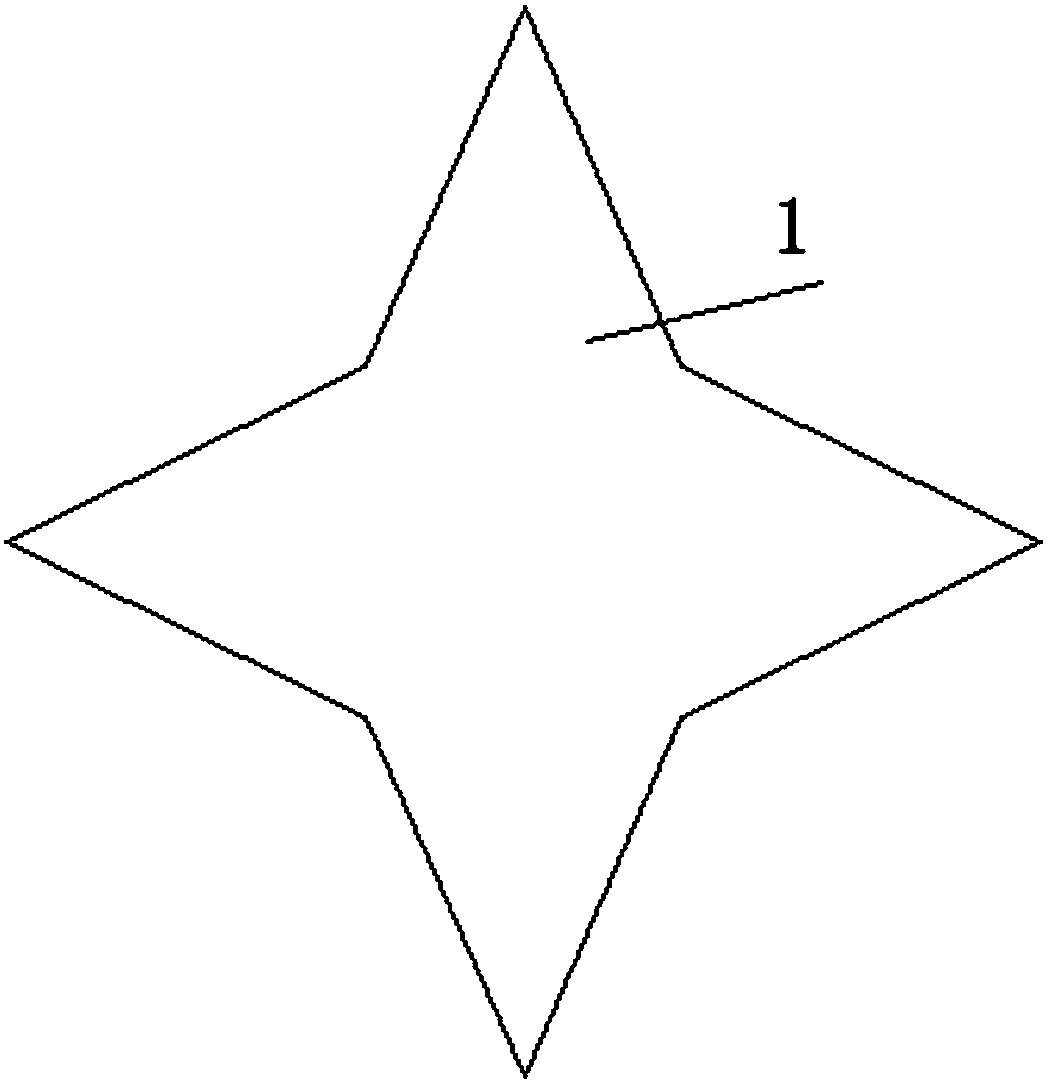

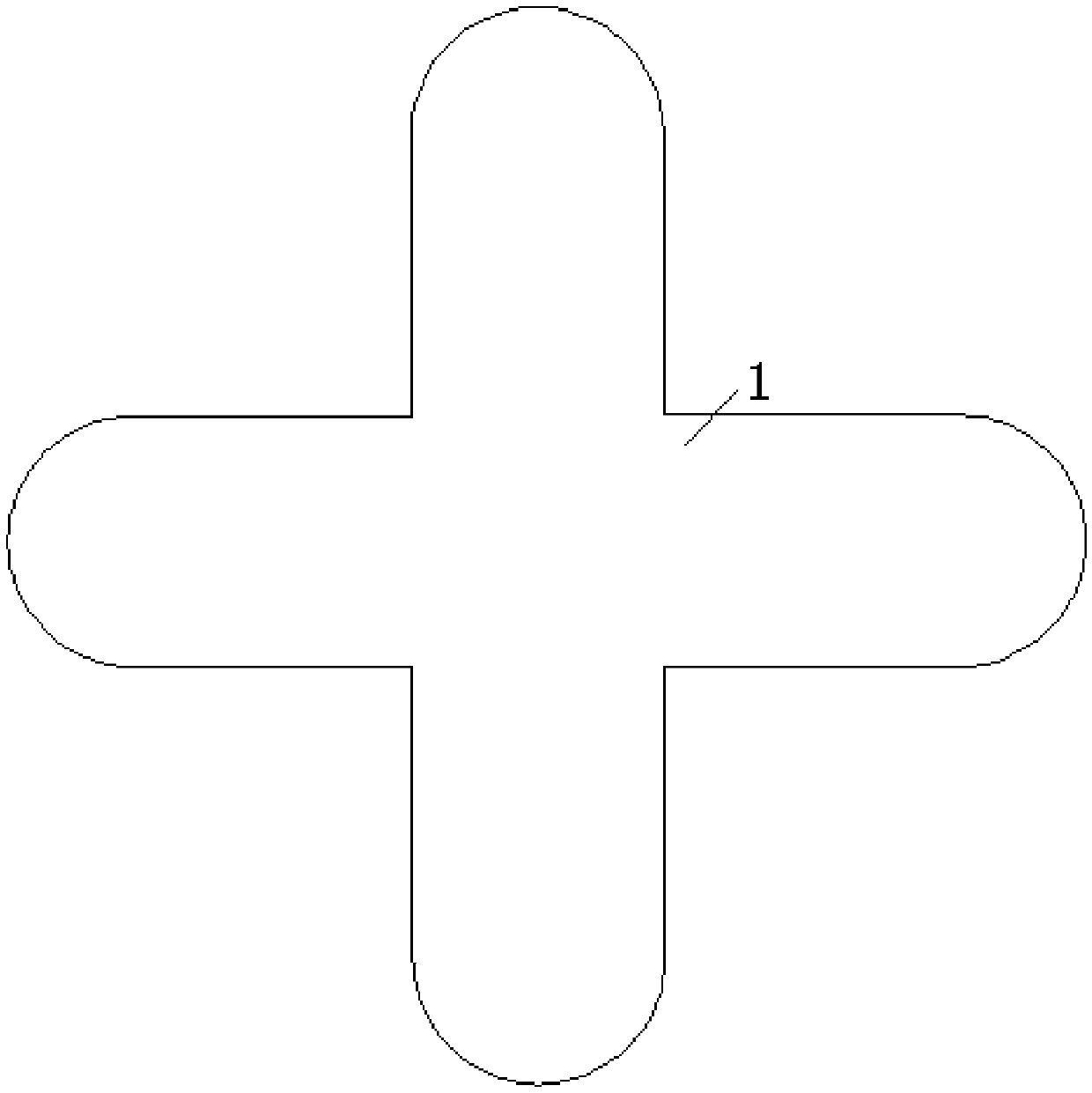

Pointed biological membrane star-shaped mold

The invention provides a pointed biological membrane star-shaped mold. The pointed biological membrane star-shaped mold comprises a long-strip-shaped wax model with a star-shaped cross section and four V-shaped top corners and with the top corner section being matched with a section of a fracture line.

Owner:锡山区东港晓鸣电子产品经营部

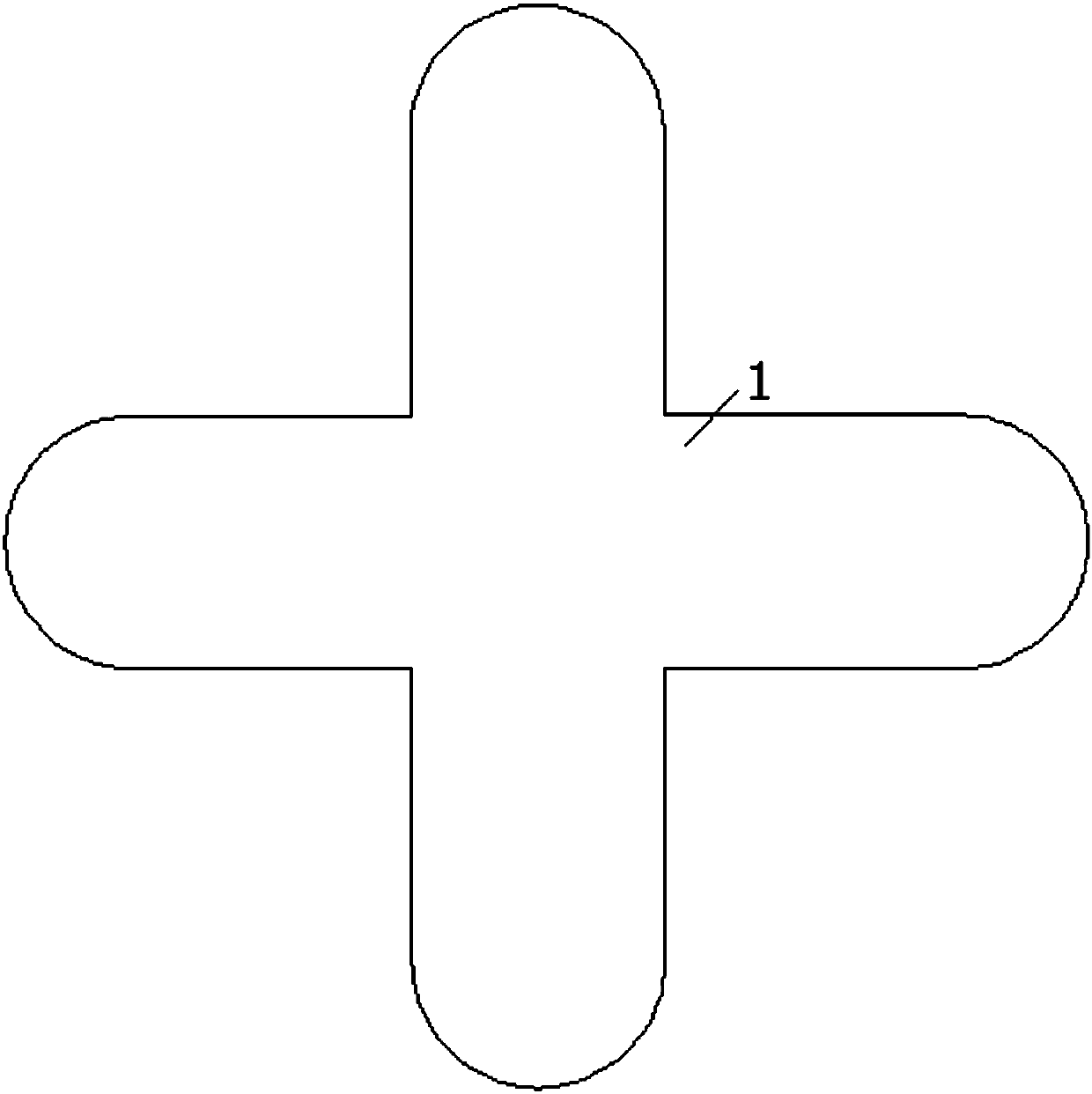

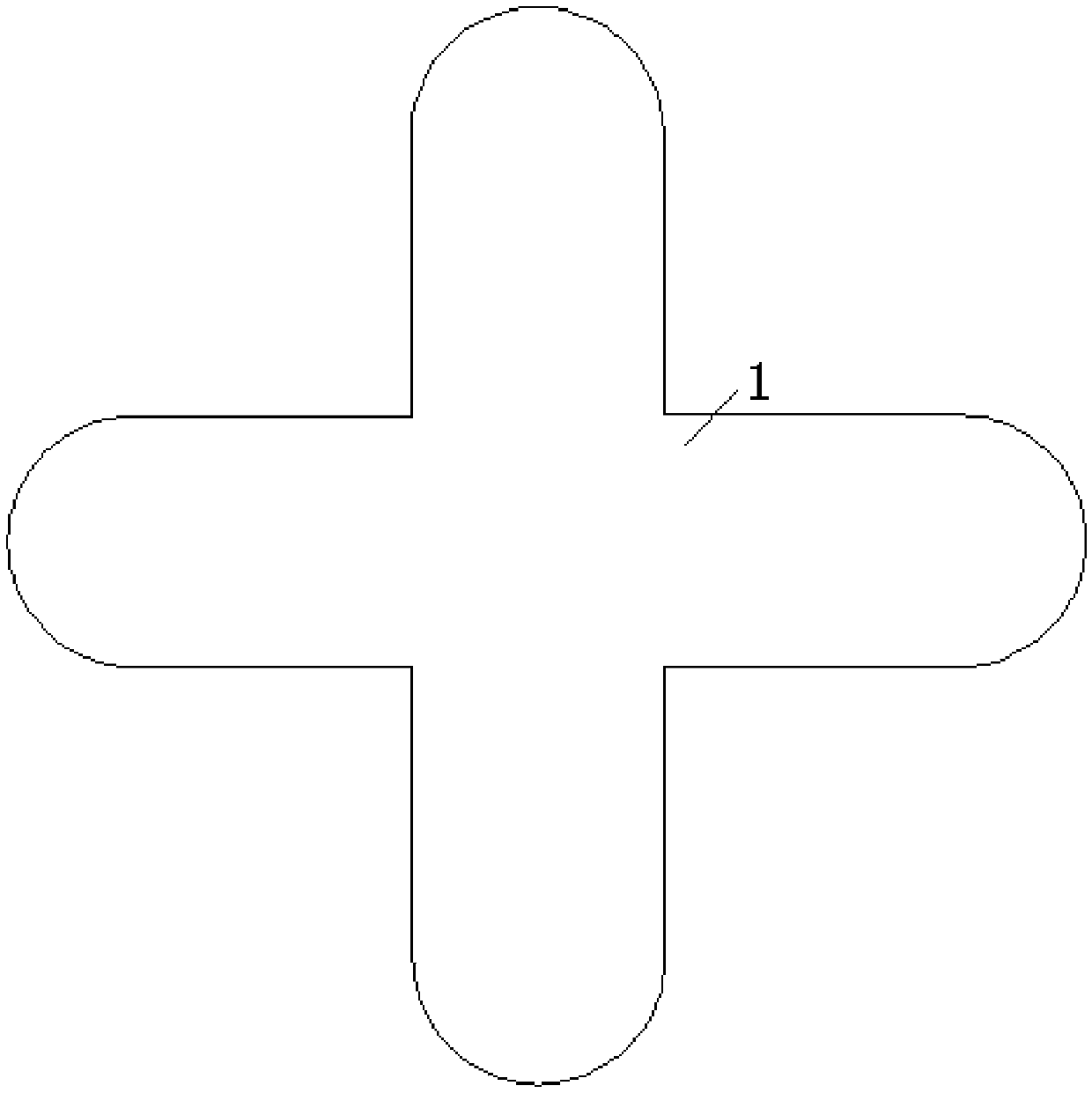

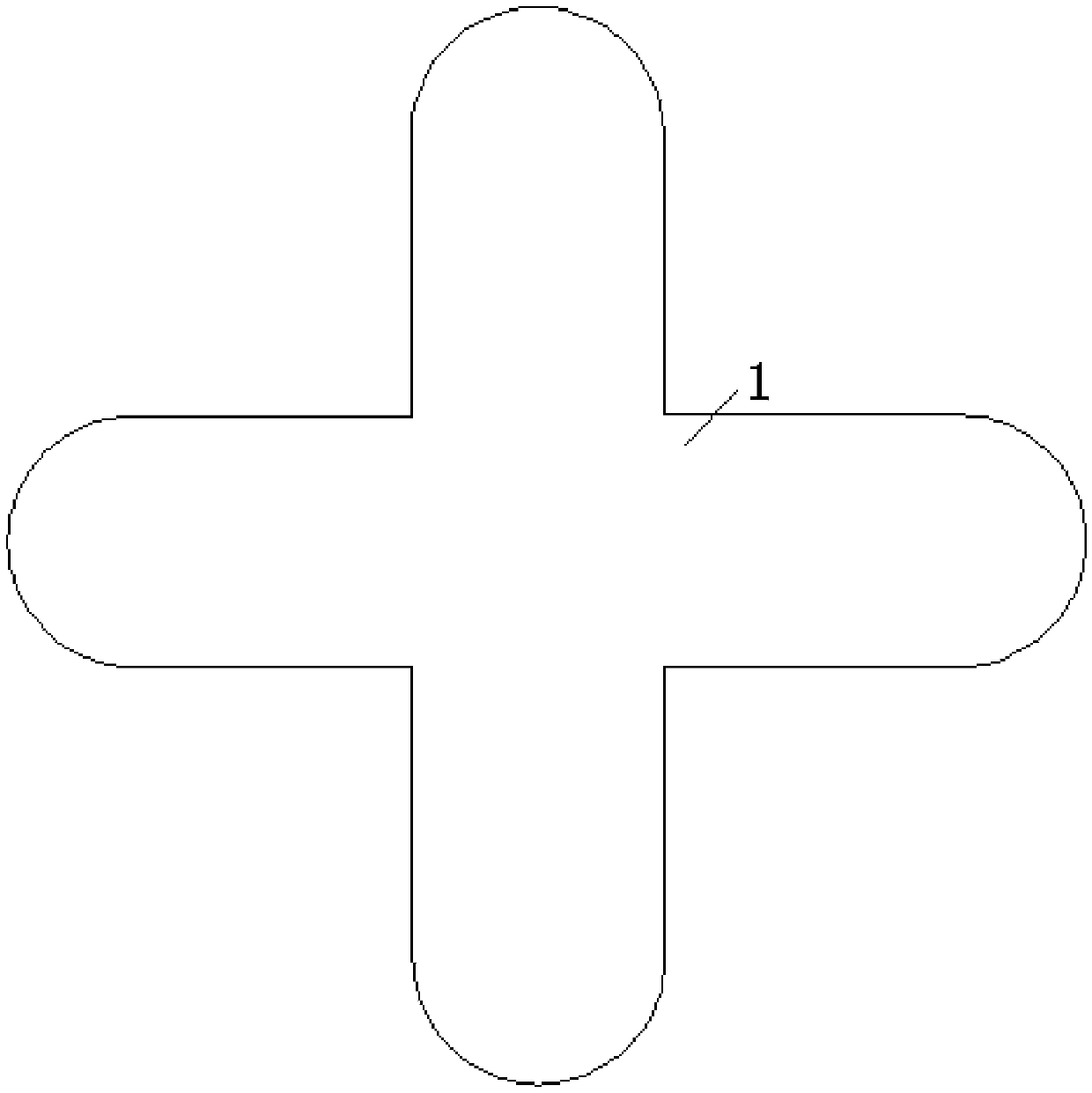

Circular type biological membrane with cross-shaped section

Circular biofilm with a cross-section, including a hollow biofilm folded into a cross-section, with four corners as "U", and the top corners coincide with the fracture line section. The inner layer of the biofilm is an elastic layer, and the outer layer is The layer is a drug layer and an elastic layer, which is a dense degradable or non-degradable biofilm. The material of the drug layer is a degradable or non-degradable, absorbent or non-absorbable or porous material that is biocompatible with human bone. The drug layer Medicines that can promote bone healing are also encapsulated inside.

Owner:锡山区东港晓鸣电子产品经营部

Batch manufacturing method of cuspate three-layer biofilm

The present invention provides a batch production method for a pointed three-layer biofilm, comprising the following steps: 1) pre-making a long strip model with a star-shaped cross-section, four "V"-shaped apexes, and the apex angle and the fracture line cross-section matching; 2) Dip the strip model into the first solution layer, the second solution layer, and the third solution layer in turn. The first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm, and the second solution layer forms a drug layer. It is encapsulated with a drug sustained-release system that promotes bone healing. The material is a degradable or absorbable substance that is biocompatible with human bone. The third solution layer forms a guide layer, and the material is biocompatible with human bone. Good compatibility with degradable or non-degradable, absorbent or non-absorbable porous loose substances; 3) After the air-drying shape of the biological microstructure membrane is fixed, according to the required size, the prepared biological microstructure membrane is elliptical along the cross-section of the elongated model. The circular biofilm after cutting was cut off from the top corner of the elongated model.

Owner:锡山区东港晓鸣电子产品经营部

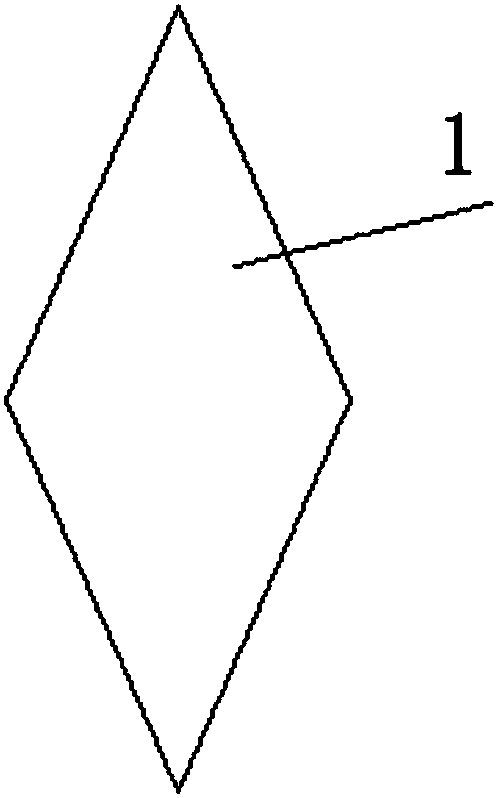

Batch production mold of pointed biological membrane

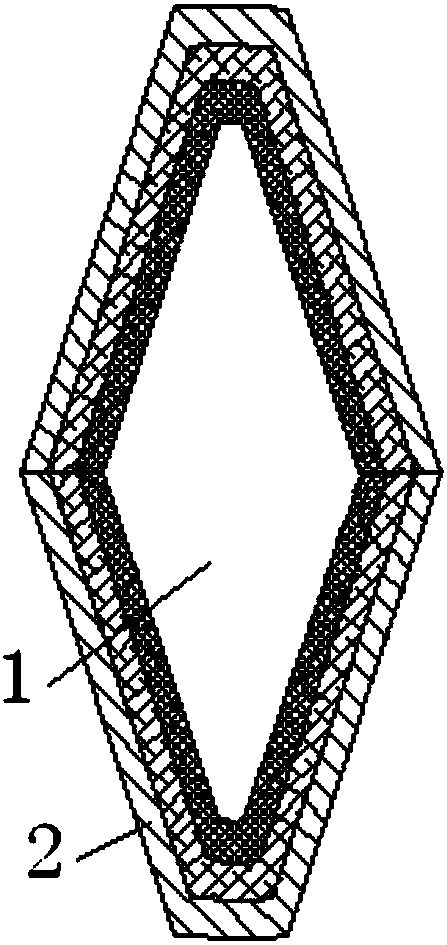

The invention provides a batch production mold of a pointed biological membrane. The mold comprises a long-strip-shaped wax model which has a diamond section, V-shaped vertex angles on the long edgesas well as matched vertex angles and bone fracture line section.

Owner:锡山区东港晓鸣电子产品经营部

Cross die for batch production of round biological membranes

The invention provides a cross-shaped mold for mass production of circular biofilms, which includes a wax model with a cross-section, four elliptical corners, and the top corners coincide with the cross-section of the fracture line.

Owner:锡山区东港晓鸣电子产品经营部

Method of preparing pointed biofilm for improving fracture healing

The invention provides a method for making a pointed biofilm to improve fracture healing, which includes the following steps: 1) making a model with a "V"-shaped top corner section in advance and matching the fracture line section; 2) making wet elastic layer, drug layer, the elastic layer is a dense degradable or non-degradable biofilm, the material of the drug layer is degradable or non-degradable, absorbable or non-absorbable or porous and loose material that is biocompatible with human bone, and the drug The drug that can promote bone healing is also encapsulated inside the layer; 3) Cover the top corner of the model with the wet elastic layer, wrap the top corner of the model and extend to both sides of the top corner of the model, and then apply the wet drug layer Covering the elastic layer to form a biological microstructure membrane; 4) After the biological microstructure membrane is air-dried and the shape is fixed, the prepared biological microstructure membrane is peeled off from the top corner of the model.

Owner:锡山区东港全宝机械经营部

Batch making method for cross model of circular biofilm

The invention provides a method for batch production of circular biofilm cross-shaped molds, which includes the following steps: 1) Manufacturing a wax model with cross-shaped cross-section, four "U" corners, and coincident corners and fracture line cross-sections. 2) Immerse the model in the first solution layer and the second solution layer in turn. The first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm. The second solution layer forms a drug layer, and the material of the drug layer is human bone Good biocompatibility degradable or non-degradable, absorbent or non-absorbable or porous loose substances, drugs that can promote bone healing are also encapsulated inside the drug layer; 3) After the biological microstructure membrane is air-dried and the shape is fixed, According to the required size, the prepared biological microstructure membrane is cut along the circumference of the ellipse of the cross section of the model, and the cut biofilm is peeled off from the top corner of the model.

Owner:锡山区东港晓鸣电子产品经营部

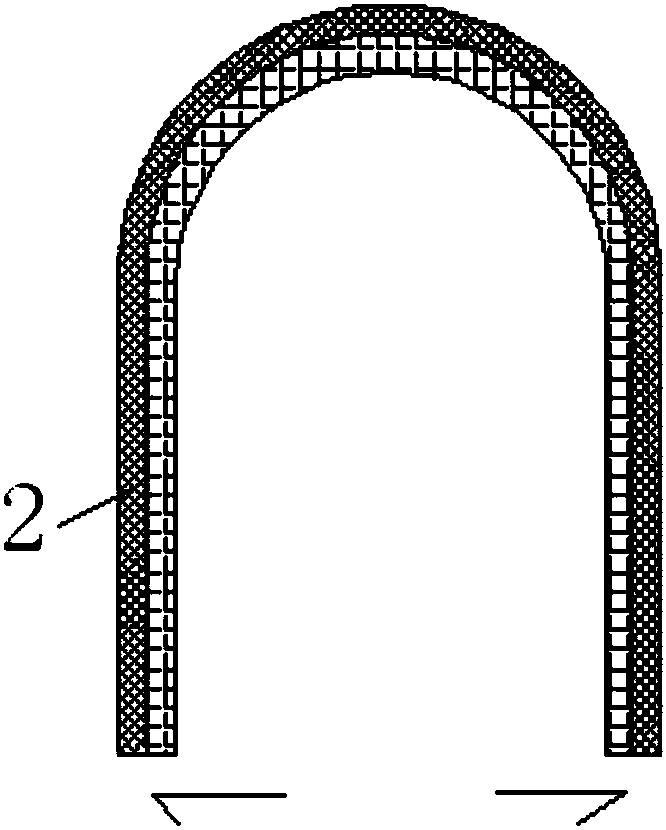

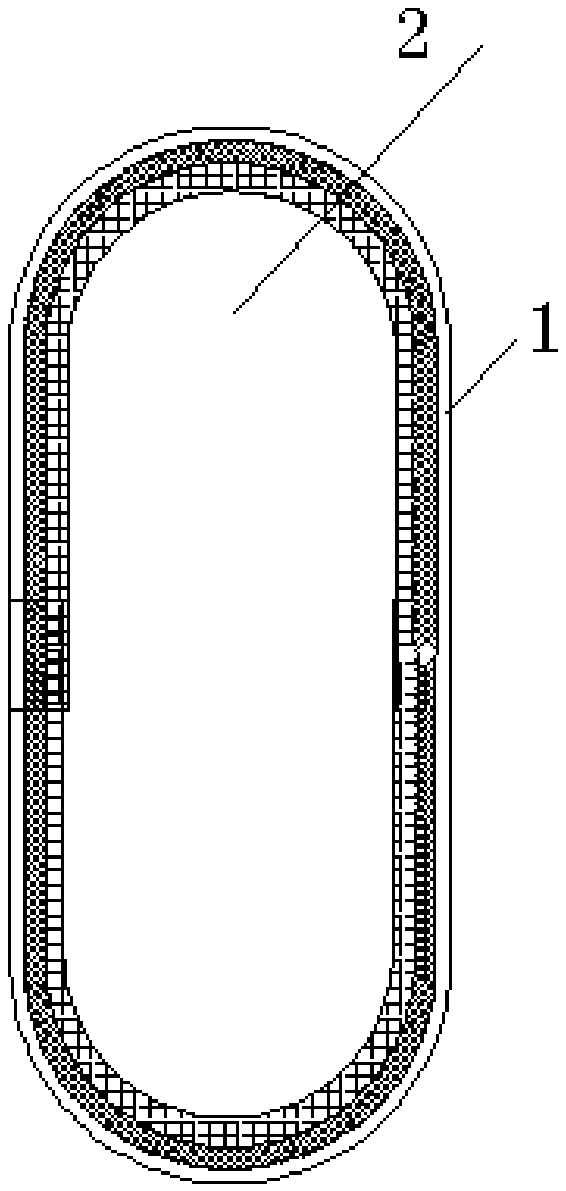

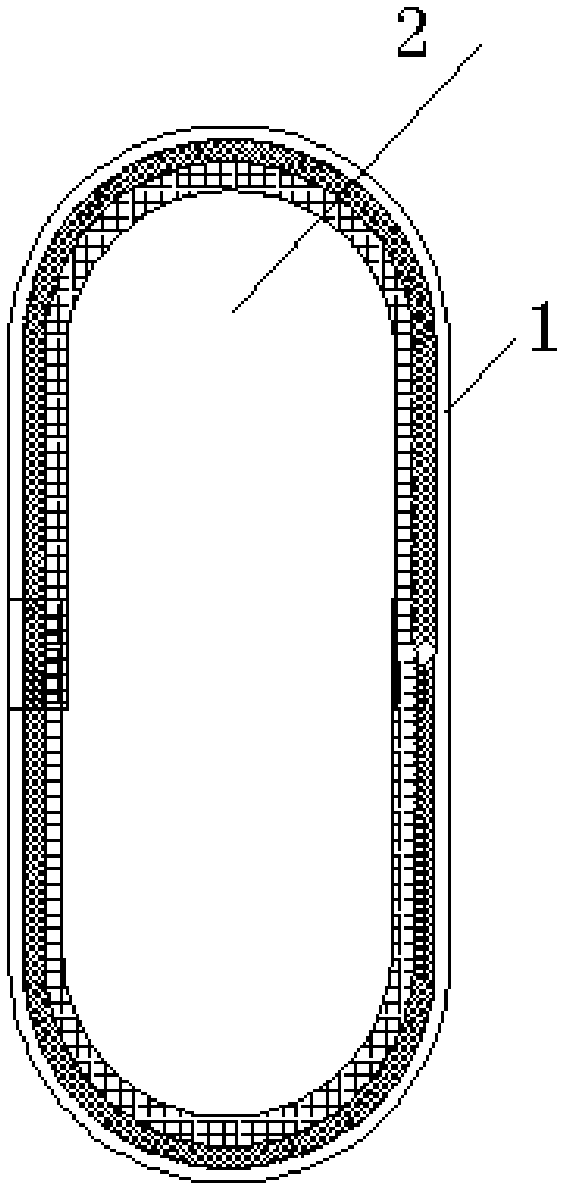

Elliptical round three-layer biological membrane

InactiveCN107822738ANon-destructive creativityCosmetic implantsMedical devicesFracture lineBiological membrane

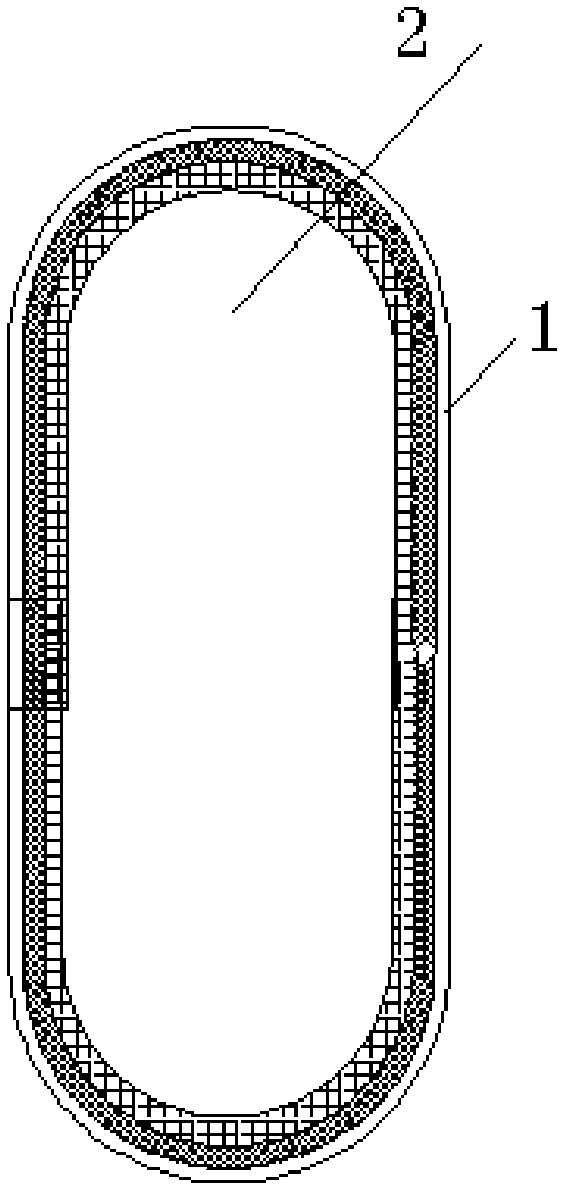

The invention provides an elliptical circular three-layer biofilm, which includes an elliptical cross-section, a ring-shaped biofilm with a "U"-shaped apex angle on the long side, and the apex angle coincides with the cross-section of the fracture line. The inner layer of the biofilm is an elastic layer, which is Dense degradable or non-degradable biofilm, the middle layer is the drug layer, encapsulated with a drug slow-release system that can promote bone healing, and the material is a biodegradable or absorbable material that is well biocompatible with human bone. The material of the outer guide layer is degradable or non-degradable, absorbable or non-absorbable porous and loose material that is biocompatible with human bone.

Owner:锡山区东港玉英家电经营部

Round biomembrane batch-production mold

The invention provides a circular biofilm batch production mold, which includes a wax model with an elliptical section, a "U"-shaped apex angle on a long side, and the apex angle coincides with the fracture line section.

Owner:锡山区东港玉英家电经营部

Star-shaped sharp biological membrane

InactiveCN107648681ANon-destructive creativitySurgeryTissue regenerationFracture lineDistal anastomosis

The invention provides a star-shaped biofilm, which includes a hollow biofilm folded into a star-shaped cross-section, with four apex angles in the shape of a "V" and the cross-section of the apex angles coincides with the cross-section of the fracture line. The biofilm is divided from the inside to the outside. It is an elastic layer and a drug layer. The elastic layer is a dense degradable or non-degradable biofilm. The material of the drug layer is a degradable or non-degradable, absorbent or non-absorbable or porous material that is biocompatible with human bone. Drugs that can promote bone healing are also encapsulated inside the layer.

Owner:锡山区东港晓鸣电子产品经营部

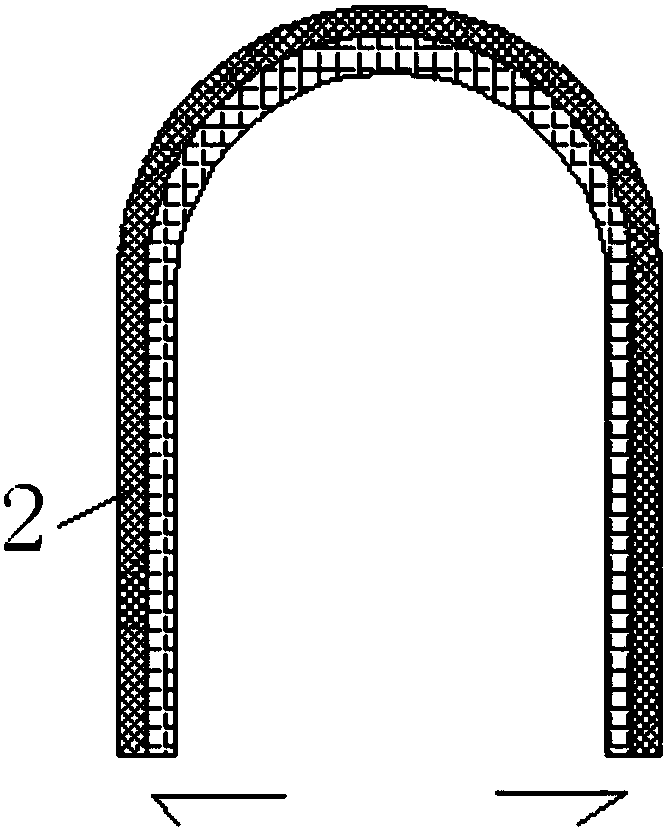

Array round biological membrane

The invention provides an array of circular biofilms, including an elastic layer and a drug layer from the inside to the outside, the elastic layer is a dense biofilm that can be degraded or absorbed, and the material of the drug layer is biocompatible with human bone biodegradable or Non-degradable, absorbable or non-absorbable porous material, the inside of the drug layer is also encapsulated with drugs that can promote bone healing, the shape of the biofilm is a structure in which unit biological particles are arranged in an array, each unit biological The bottom of the particles is 3-5 mm apart from each other. The biological microstructure membrane is a strip-shaped folded structure with a "U"-shaped cross-section. The inner part is an elastic layer and the outer part is a drug layer. The "U"-shaped cross-section The ratio of width to depth is 0.5‑1.5, where the width is the gap between broken bone surfaces that are spliced together after fracture surgery.

Owner:锡山区东港玉英家电经营部

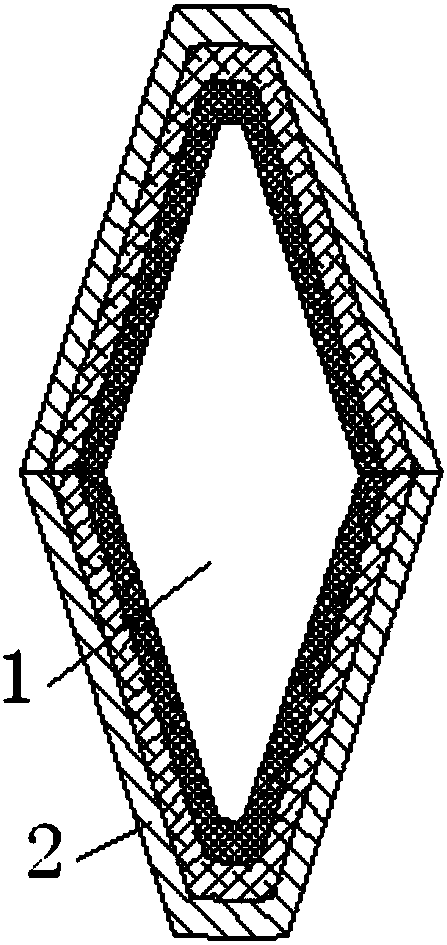

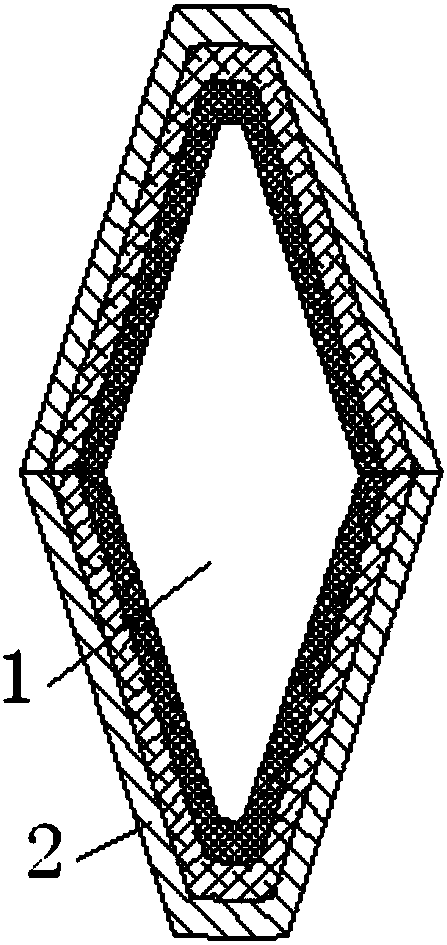

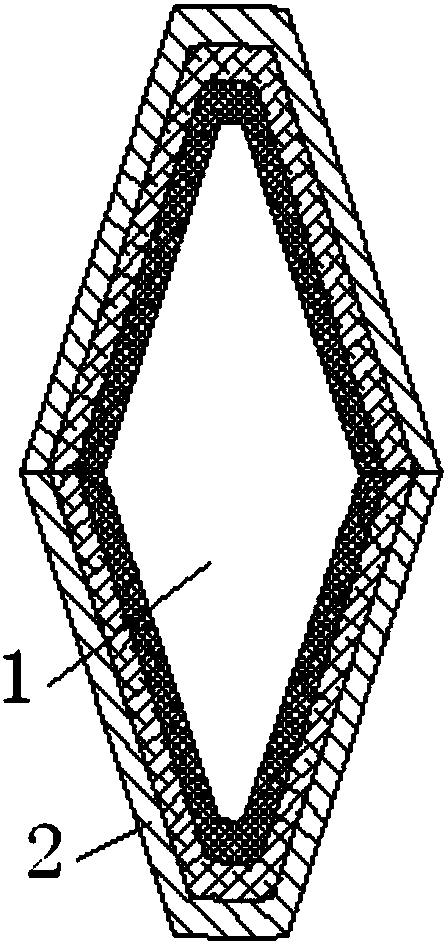

Rhombic pointed biomembrane

Diamond-shaped biofilms, including ring-shaped biofilms with rhombus-shaped cross-section, "V"-shaped top angle on the long side, and the top angle coincides with the cross-section of the fracture line. The inner layer of the biofilm is an elastic layer, the outer layer is a drug layer, and the elastic layer , which is a dense degradable or non-degradable biofilm. The material of the drug layer is a porous and loose material that is biocompatible with human bone, degradable or non-degradable, absorbable or non-absorbable, and inside the drug layer is also encapsulated. Drugs that promote healing.

Owner:锡山区东港晓鸣电子产品经营部

Batch preparation method for circular biological membrane

The invention provides a method for batch production of circular biofilms, which includes the following steps: 1) making a model in advance with an elliptical cross-section and a "U"-shaped apex angle on the long side, and the apex angle coincides with the fracture line section; 2) making the model Immerse in the first solution layer and the second solution layer in turn, the first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm, the second solution layer forms a drug layer, and the material of the drug layer is biocompatible with human bone Degradable or non-degradable, absorbent or non-absorbable or porous and loose substances, drugs that can promote bone healing are also encapsulated inside the drug layer; 3) After the biological microstructure membrane is air-dried and the shape is fixed, the required size The prepared biological microstructure membrane is cut along the circumference of the ellipse of the cross-section of the model, and the ring-shaped biofilm after cutting is peeled off from the top corner of the model.

Owner:锡山区东港玉英家电经营部

Batch manufacturing method of cuspate biofilm

The invention provides a method for batch production of pointed biofilms, which includes the following steps: 1) Pre-fabricating a model with a diamond-shaped cross section, a "V"-shaped vertex angle on the long side, and the vertex angle coincides with the fracture line section; 2) sequentially making the model Immersed in the first solution layer and the second solution layer, the first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm, and the second solution layer forms a drug layer, and the material of the drug layer is biocompatible with human bone Degradable or non-degradable, absorbent or non-absorbable or porous and loose substances, drugs that can promote bone healing are also encapsulated inside the drug layer; 3) After the biological microstructure membrane is air-dried and fixed, the size of The prepared biological microstructure membrane is cut along the circumference of the model section, and the cut ring-shaped biofilm is peeled off from the top corner of the model; 4) The ring-shaped biofilm is cut into a "V"-shaped biofilm.

Owner:锡山区东港晓鸣电子产品经营部

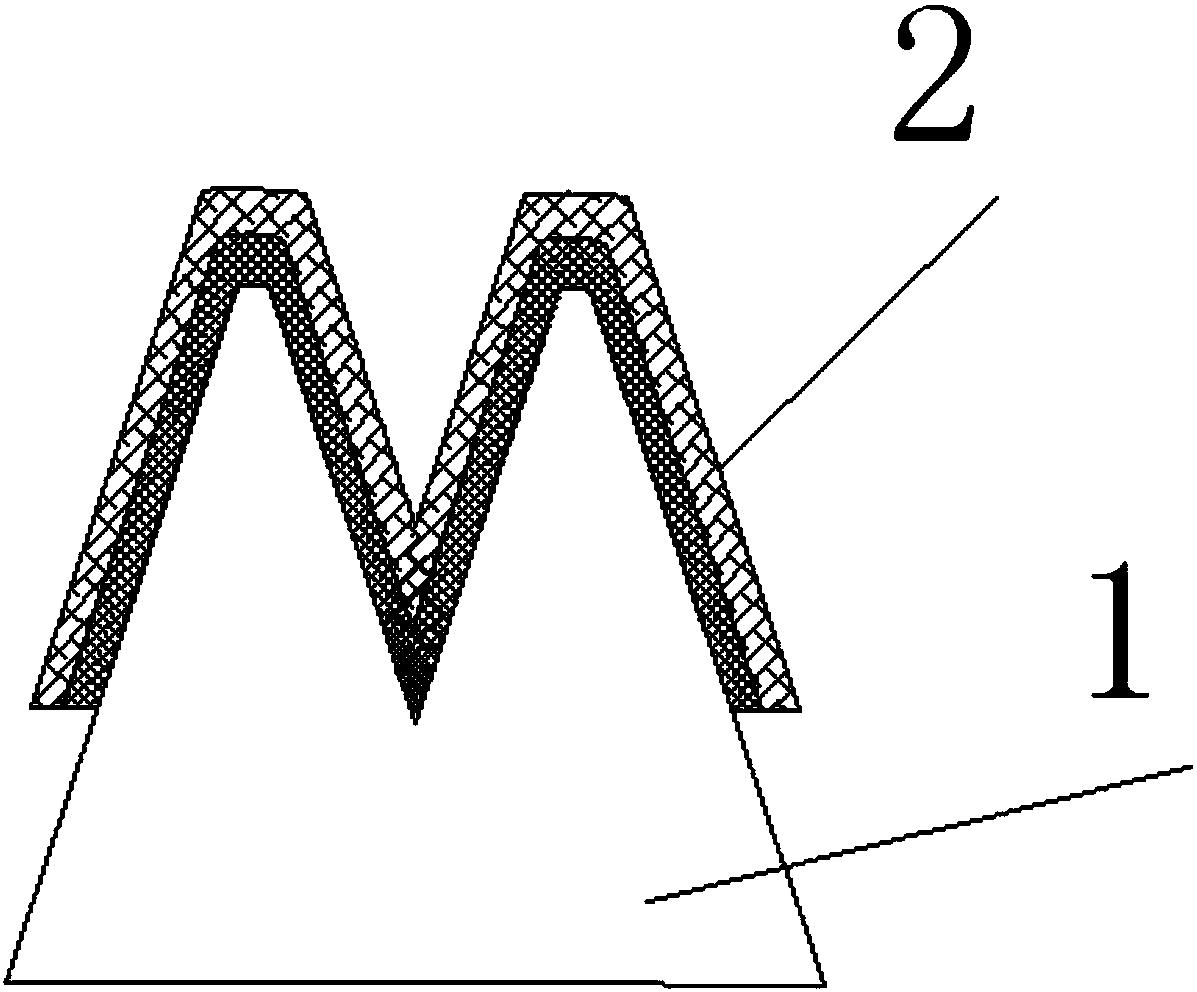

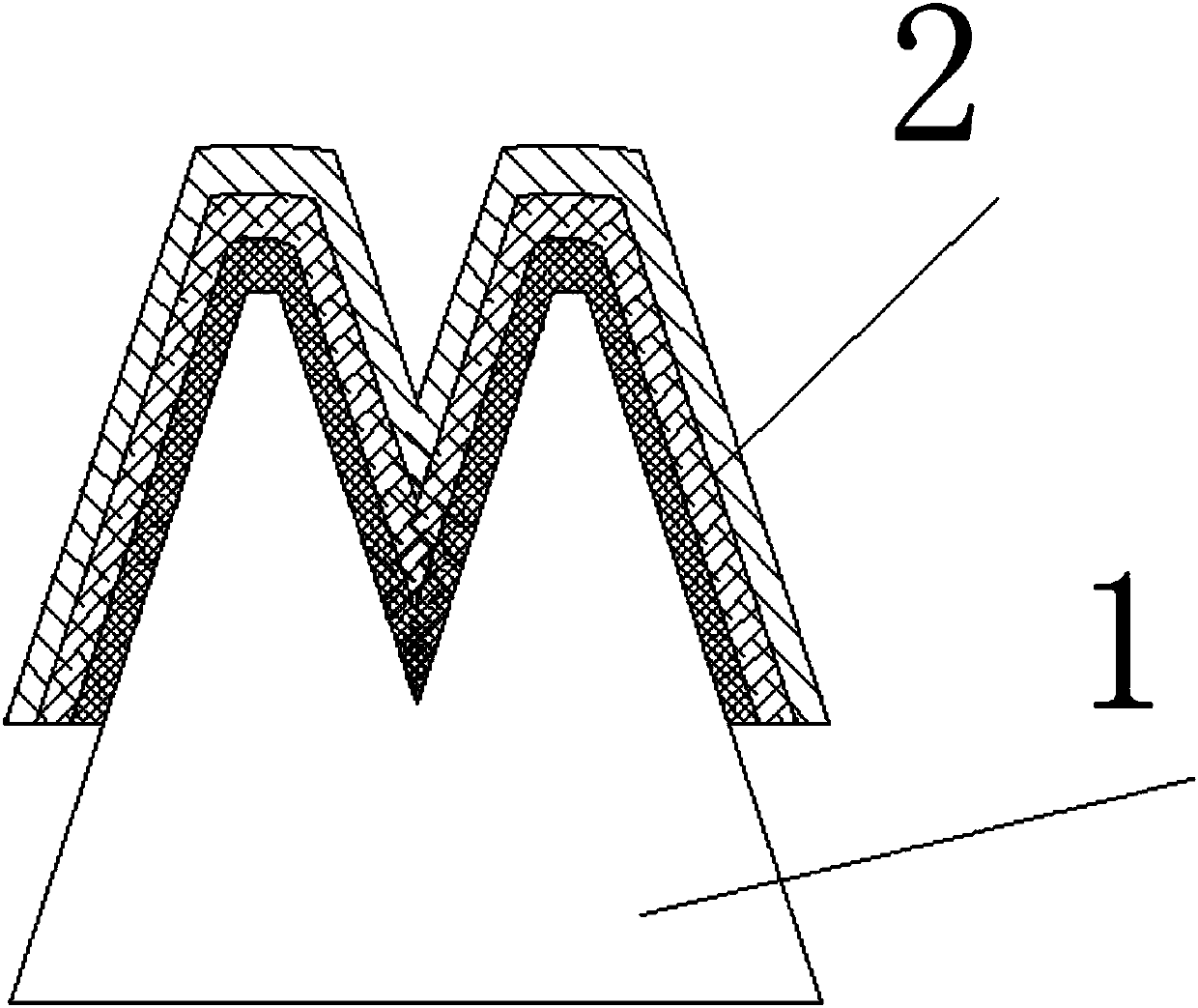

Production method of ''W'' model of sharp biological membrane for improving fracture healing

The present invention provides a "W" model manufacturing method of a pointed biofilm for improving fracture healing. 2) Wet elastic layer and drug layer are respectively made, the elastic layer is a dense degradable or non-degradable biofilm, and the material of the drug layer is degradable or non-degradable with good biocompatibility with human bone, Absorb or not absorb or porous porous substances, and the drug layer is also encapsulated with drugs that promote bone healing; 3) The moist elastic layer is covered on the two raised peaks of the model, wrapping the two models. The raised peaks extend to both sides of the top corner of the model, and then the wet drug layer is covered on the elastic layer to form a biomicrostructure film; 4) After the biomicrostructure film is air-dried and the shape is fixed, the fabricated biomicrostructure The membrane peels off the top corners of the model. 5), cut the "W" type membrane into a "V" type membrane.

Owner:锡山区东港玉英家电经营部

Array three-layer circular composite film

InactiveCN107822737APromote growthImprove performanceCosmetic implantsMedical devicesComposite filmAbsorbent material

The invention provides an array three-layer circular composite film which comprises an elastic layer, a medicine layer and a guiding layer from interior to exterior. The elastic layer is a dense degradable or non-degradable biological film, the medicine layer packs a medicine sustained release system having the promoting effect on sclerotin healing, the medicine layer is made of degradable or absorbable materials with the good biological compatibility with human sclerotin, the guiding layer is made of degradable or non-degradable and absorbable or non-absorbable porous bulk materials with thegood biological compatibility with human sclerotin, the biological film is of a structure arrayed by unit biological particles, the bottoms of the unit biological particles are arranged at the interval being 3-5 mm, the unit biological particles are of a long strip shaped folding structure, the section is in a U shape, the elastic layer is arranged inside, the medicine layer is arranged on the outmost layer, the ratio of the width to depth of the U-shaped section is 0.5-1.5, and the width is the interval between spliced broken bone surfaces after facture surgical treatment.

Owner:锡山区东港玉英家电经营部

Production method of ''W'' model of three-layer sharp composite membrane for improving fracture healing

The invention provides a production method of a ''W'' model of a three-layer sharp composite membrane for improving fracture healing. The production method comprises the following steps: (1) producinga model in advance, wherein a vertex angle section of the model is inversed ''W''-shaped, and two protruded peaks are matched with a fracture line section; (2) respectively producing a wet elastic layer, a wet medicine layer and a wet guiding layer, wherein the elastic layer is a dense degradable or non-degradable biofilm, a medicine slow-release system with a bone healing promoting effect is encapsulated in the medicine layer, the medicine layer is produced from a material which is good in biocompatibility with human bones and is degradable or absorbent, and the guiding layer is produced from a porous loose material which is good in biocompatibility with human bones and is degradable or non-degradable and absorbent or non-absorbent; (3) covering the two protruded peaks of the model withthe wet elastic layer so as to cover the two protruded peaks, enabling the elastic layer to extend to two sides of the vertex angle of the model, covering the elastic layer with the wet medicine layer, and covering the medicine layer with the wet guiding layer; (4) after the three-layer composite film is air-dried and fixed in shape, stripping the three-layer composite film from the vertex angle of the model; and (5) cutting a ''W''-shaped membrane into a ''V''-shaped membrane.

Owner:锡山区东港玉英家电经营部

Method for making model array of three-layer circular composite film

The invention provides a method for making a model array of a three-layer circular composite membrane, comprising the following steps: 1) making a model whose apex angle cross-section is "U"-shaped and the fracture line cross-section is consistent, and the "U"-shaped model is combined into an array, and each The distance between the bottom of the "U" model is 3-5 mm; 2) Make a wet elastic layer, drug layer, and guide layer. The elastic layer is a dense degradable or non-degradable biofilm, and the drug layer is encapsulated to promote bone healing. The active drug sustained release system, the material of the guide layer is a degradable or non-degradable, absorbent or non-absorbable porous substance; 3) Cover the wet elastic layer on the model array, wrap the top corner of each model in the array and extend to the periphery of the model array, and then cover the wet drug layer on the elastic layer in the same range to form a biological microstructure membrane; 4) After the biological microstructure membrane is air-dried and fixed, place the biological Membrane shearing, peeling off the fabricated single biological microstructure membrane from the model.

Owner:锡山区东港玉英家电经营部

Round three-layer biological membrane with cross-shaped section

The present invention provides a circular three-layer biofilm with a cross-section, including a hollow biofilm folded into a cross-section, with four corners "U", and the corners coincide with the fracture line section, and the inner layer of the biofilm It is an elastic layer, which is a dense degradable or non-degradable biofilm, and the middle layer is a drug layer, which encapsulates a drug slow-release system that can promote bone healing. The material is biodegradable or biocompatible with human bone. The absorbable material, the outer guiding layer, is made of degradable or non-degradable, absorbable or non-absorbable porous and loose material that is biocompatible with human bone.

Owner:锡山区东港晓鸣电子产品经营部

Three-layer circular composite particle for improving fracture healing

InactiveCN107773329ANon-destructive creativityBone implantJoint implantsParticulatesAbsorbent material

The invention provides a three-layer circular composite particle for improving fracture healing, which includes a granular biofilm with a width to height ratio of 2:1 to 1:1, an elastic layer from the inside to the outside of the granular biofilm, and a medicine Layer and guide layer, the elastic layer is a dense degradable or non-degradable biofilm, the drug layer encapsulates a drug slow-release system that can promote bone healing, and the material is biocompatible with human bone. Degradable or absorbable material, the material of the guide layer is a degradable or non-degradable, absorbent or non-absorbable porous material that is biocompatible with human bone, and the biological microstructure membrane is a strip-shaped folded structure with a cross-section "U" shape, the inner part is an elastic layer, and the outermost part is a drug layer. The width and depth ratio of the "U" shape section is 0.5-1.5, and its width is between the broken bone surfaces spliced together after fracture surgery. gap.

Owner:锡山区东港晓鸣电子产品经营部

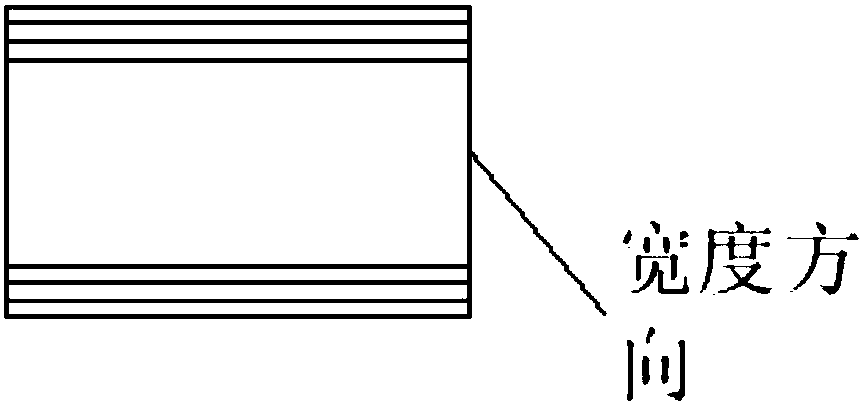

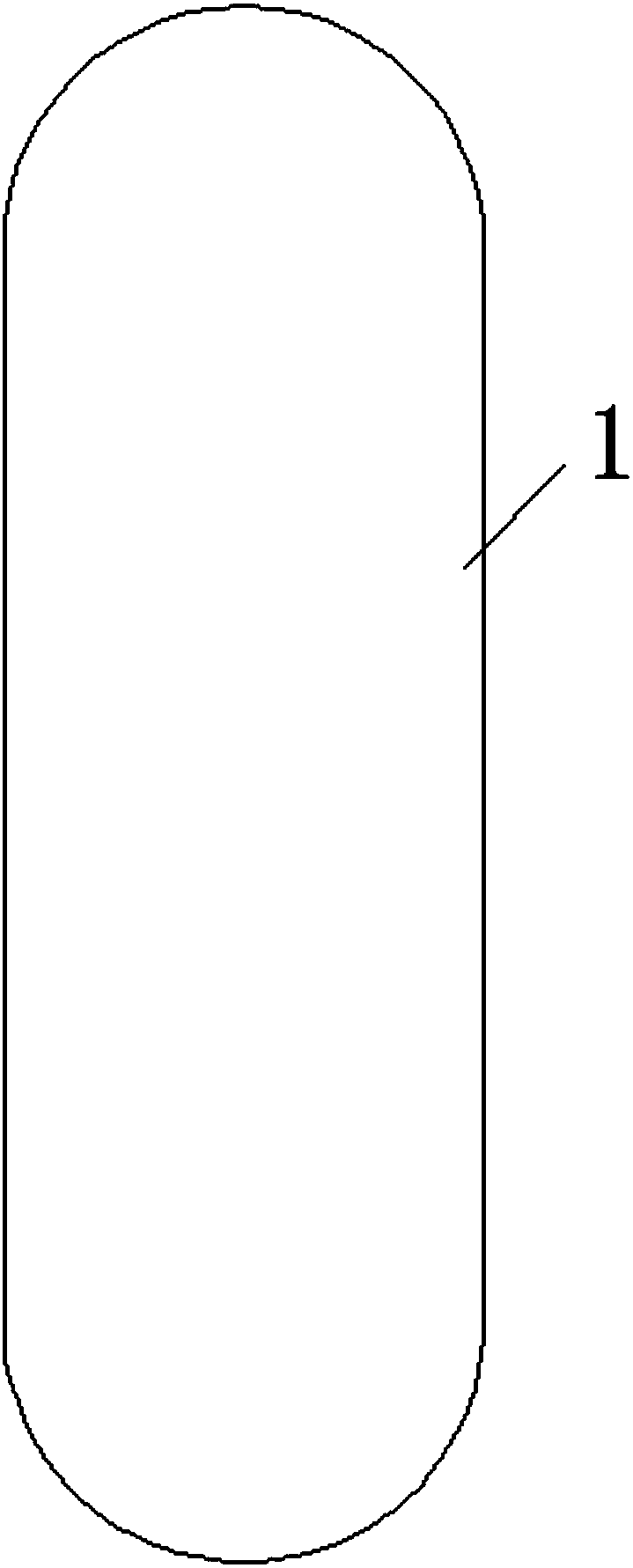

Circular composite particle for improving fracture healing

The invention provides a circular composite particle for improving fracture healing. The circular composite particle comprises a particle-shaped biological membrane with the ratio of width to height being (2:1)-(1:1), and the particle-shaped biological membrane comprises an elastic layer and a medicine layer from inside to outside; the elastic layer is a dense degradable or absorbable biological membrane, and the medical layer is made of porous loose materials which have good compatibility with human bone substances, are degradable or undegradable, can be absorbed or cannot be absorbed; medicine which has a promotion effect on bone substance healing is further packaged in the medicine layer, the biological micro-structure membrane is of a long-strip-shaped folded structure, the cross section is in a U shape, the inner portion of the composite particle is the elastic layer, and the outer portion of the composite particle is the medicine layer; the ratio of the width to the depth of theU-shaped cross section is 0.5-1.5, and the width is the gap between the surfaces of broken bones which are spliced together after fracture surgery.

Owner:锡山区东港晓鸣电子产品经营部

Production method of three-layered pointed composite film for improving fracture healing

The invention provides a method for making a three-layer pointed composite membrane for improving fracture healing, which includes the following steps: 1) making a model whose top corner section is "V" and coincides with the fracture line section in advance; 2) separately making wet The elastic layer, the drug layer, and the guide layer, the elastic layer is a dense degradable or non-degradable biofilm, the drug layer is encapsulated with a drug slow-release system that can promote bone healing, and the material is made of human bone bio A well-compatible degradable or absorbable material, the material of the guide layer is a degradable or non-degradable, absorbable or non-absorbable porous material that is biocompatible with human bone; 3) Cover the wet elastic layer on the model On the top corner, wrap the top corner of the model and extend to both sides of the top corner of the model, then cover the wet drug layer on the elastic layer, and then cover the wet guide layer on the drug layer; 4) press the biological microstructure membrane It is necessary to cut off in the width direction; 5) After the composite particles are air-dried and the shape is fixed, the prepared composite particles are peeled off from the top corner of the model.

Owner:锡山区东港全宝机械经营部

Batch production method of pointed three-layer biological membrane

The invention provides a batch production method of a pointed three-layer biological membrane. The method comprises steps as follows: 1) a model which has a diamond section, V-shaped vertex angles onthe long edges as well as matched vertex angles and bone fracture line section is made in advance; 2) the model is soaked in a first solution layer, a second solution layer and a third solution layersequentially, wherein the first solution layer forms an elastic layer which is a compact and degradable or non-degradable biological membrane, the second solution layer is a medicine layer, is coatedwith a drug release system with a promoting function on bone healing and is made of a degradable or non-degradable material with good biocompatibility with human bone, and the third solution layer isa guide layer and is made of a degradable or non-degradable and absorbent or non-absorbent porous bulk material with good biocompatibility with human bone; 3) when a biological microstructural membrane is air-dried and has a fixed shape, the well prepared biological microstructural membrane in required size is cut along the circumference of the section of the model, the cut annular biological membrane is stripped from the vertex angles; 4) the annular biological membrane is sheared, and the V-shaped biological membrane is obtained.

Owner:锡山区东港晓鸣电子产品经营部

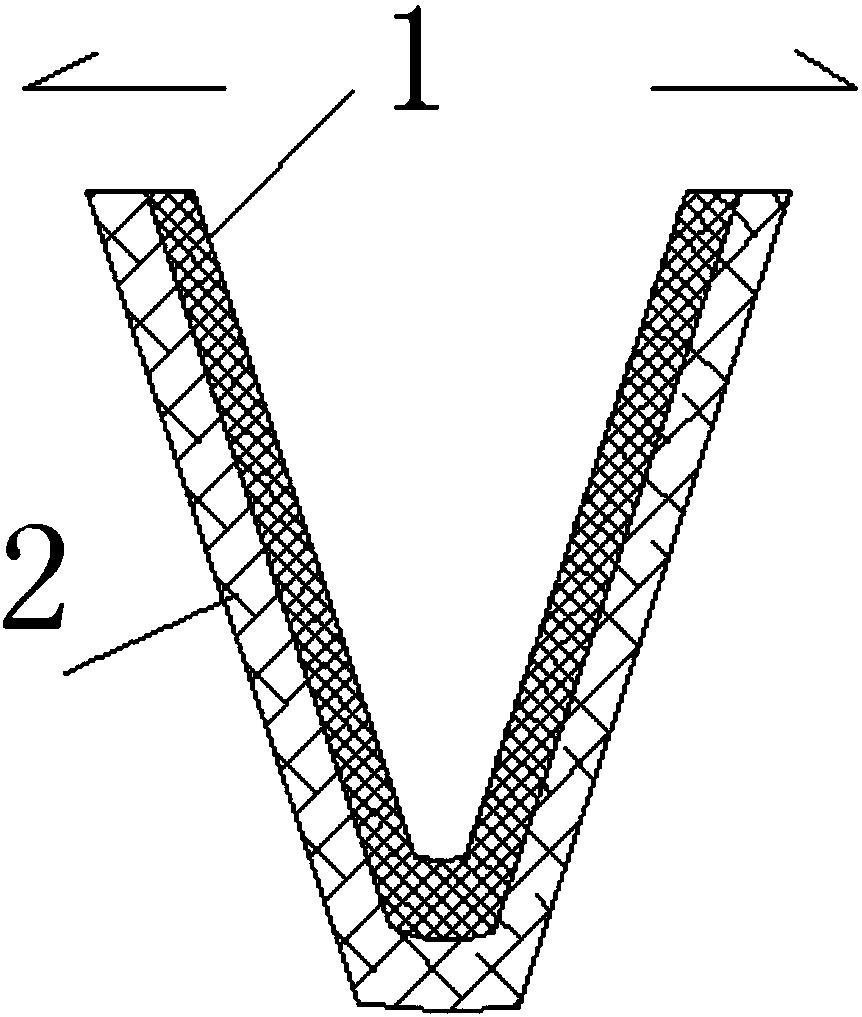

Three-layer sharp compound film for improving fracture healing

The invention provides a three-layer pointed composite film for improving fracture healing, which includes an elastic layer, a drug layer, and a guiding layer from the inside to the outside, the elastic layer is a dense degradable or non-degradable biofilm, and the drug layer encapsulates There is a drug slow-release system that can promote bone healing. The material is a degradable or absorbable material that is biocompatible with human bone. The material of the guide layer is biocompatible or non-degradable. It is a porous and loose substance that absorbs or does not absorb. The biological microstructure membrane is a long strip-shaped folded structure with a "V"-shaped cross section. The inner part is an elastic layer, and the outermost layer is a drug layer. The "V"-shaped The section width to depth ratio is 0.5‑1.5, with the width being the gap between fractured bone surfaces spliced together after fracture surgery.

Owner:锡山区东港全宝机械经营部

Diamond and pointed three-layer biological membrane

The invention provides a diamond and pointed three-layer biological membrane. The biological membrane comprises a diamond biological membrane which has a diamond section, V-shaped vertex angles on thelong edges as well as matched vertex angles and fracture line section and is hollow inside, wherein the inner layer of the biological membrane is an elastic layer which is a compact and degradable ornon-degradable biological membrane, the middle layer is a drug layer, wraps a drug sustained release system with a promoting function on bone healing and is made of a degradable or absorbable material with good biocompatibility with human bone, and the outer layer is a guide layer and is made of a degradable or non-degradable and absorbable or non-absorbable porous bulk material with good biocompatibility with human bone.

Owner:锡山区东港晓鸣电子产品经营部

Batch making method for circular three-layer biofilm

The invention provides a batch production method of a circular three-layer biofilm, which includes the following steps: 1) making a model in advance with an elliptical cross-section, a "U"-shaped apex angle on the long side, and a coincident apex angle with the fracture line section; 2) The model is immersed in the first solution layer, the second solution layer, and the third solution layer in turn. The first solution forms an elastic layer, which is a dense degradable or non-degradable biofilm. The second solution layer forms a drug layer, which encapsulates the bone The drug slow-release system that can promote bone healing is made of degradable or absorbable substances that are biocompatible with human bone. The third solution layer forms a guiding layer, and the material is biodegradable and biocompatible with human bone. Or non-degradable, absorbent or non-absorbing porous substances; 3) After the bio-microstructure membrane is air-dried and the shape is fixed, cut the prepared bio-microstructure membrane along the circumference of the model cross-section ellipse according to the required size, and after cutting A ring-shaped biofilm peeled from the top corner of the model.

Owner:锡山区东港玉英家电经营部

Three-layer pointed composite particles improving fracture healing

The invention provides a three-layer pointed composite particle for improving fracture healing, which includes a granular biofilm with a width to height ratio of 2:1 to 1:1, an elastic layer from the inside to the outside of the granular biofilm, and a medicine layer, the elastic layer is a dense degradable or absorbable biofilm, the material of the drug layer is a degradable or non-degradable, absorbable or non-absorbable porous material that is biocompatible with human bone, and the drug layer also contains Sealed with drugs that can promote bone healing, the biological microstructure membrane is a long strip-shaped folded structure with a "V"-shaped cross section, an elastic layer inside and a drug layer outside, and the "V"-shaped The section width to depth ratio is 0.5‑1.5, with the width being the gap between fractured bone surfaces spliced together after fracture surgery.

Owner:锡山区东港全宝机械经营部

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com