Method for making sharp composite particles for improving fracture healing

A composite particle, fracture healing technology, used in bone implants, medical science, prostheses, etc., can solve the problem of small fracture area, inability to fit effectively, and biocomposite membrane degradation speed time performance indicators can not meet clinical needs. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

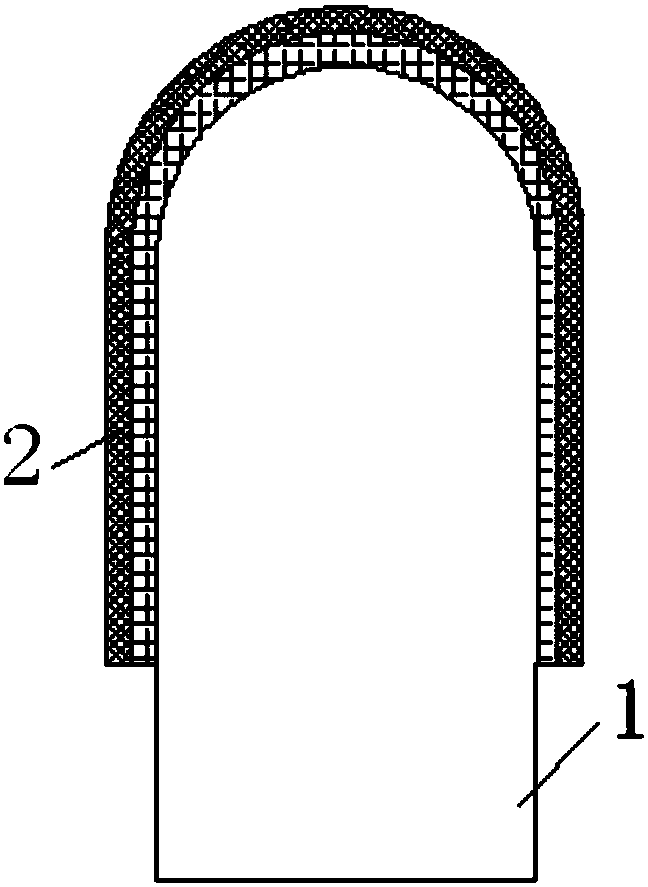

[0038] refer to figure 1 , one A kind of preparation method of the pointed composite granule that improves fracture healing, comprises the following steps:

[0039] 1) Make the fracture line after artificial fracture with isolated human bone, pour wax on the fracture line, and then form a "U"-shaped model 1 after the wax solidifies. Take Model 1 off the fracture line.

[0040]2) Make wet elastic layer and drug layer respectively, the elastic layer is a dense degradable or non-degradable biofilm, and the material of the drug layer is biocompatible with human bone, degradable or non-degradable, absorbable or non-absorbable Or the porous and loose material, the drug layer is also encapsulated with drugs that can promote bone healing.

[0041] 3) Cover the top corner of model 1 with the wet elastic layer, wrap the top corner of model 1 and extend to both sides of the top corner of model 1, then cover the wet drug layer on the elastic layer, and then cover the wet guide layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com