Manufacturing method of circular biofilm model array

A production method and biofilm technology, which is applied in medical science, surgery, etc., can solve the problems of small fracture area, ineffective fit, biocomposite film degradation speed and time performance indicators that cannot meet clinical needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

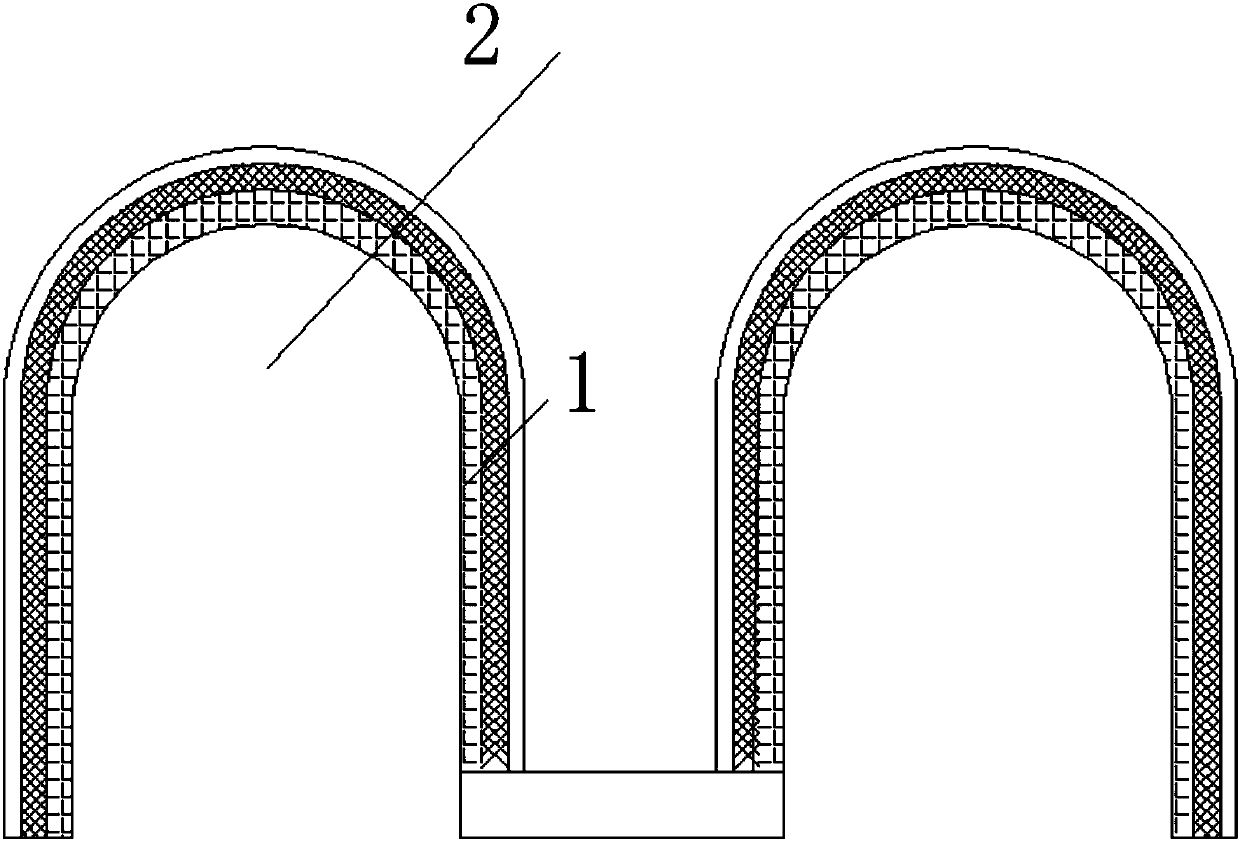

[0035] refer to figure 1 1. A method for making a circular biofilm model array, comprising the following steps:

[0036] 1) Make a model 2 with a "U"-shaped top corner section that matches the fracture line section in advance, and combine the "U"-shaped models 2 close to each other to form an array, and the bottom of each "U"-shaped model 2 is spaced at a distance of 3 -5 mm;

[0037] 2) Make wet elastic layer and drug layer respectively, the elastic layer is a dense degradable or non-degradable biofilm, and the material of the drug layer is biocompatible with human bone, degradable or non-degradable, absorbable or non-absorbable Or a porous and loose substance, the inside of the drug layer is also encapsulated with drugs that can promote bone healing;

[0038]3) Cover the wet elastic layer on the model array, wrap the top corner of each model in the array and extend to the periphery of the model array, and then cover the wet drug layer on the elastic layer in the same range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com