Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3results about How to "Decreases bowing profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

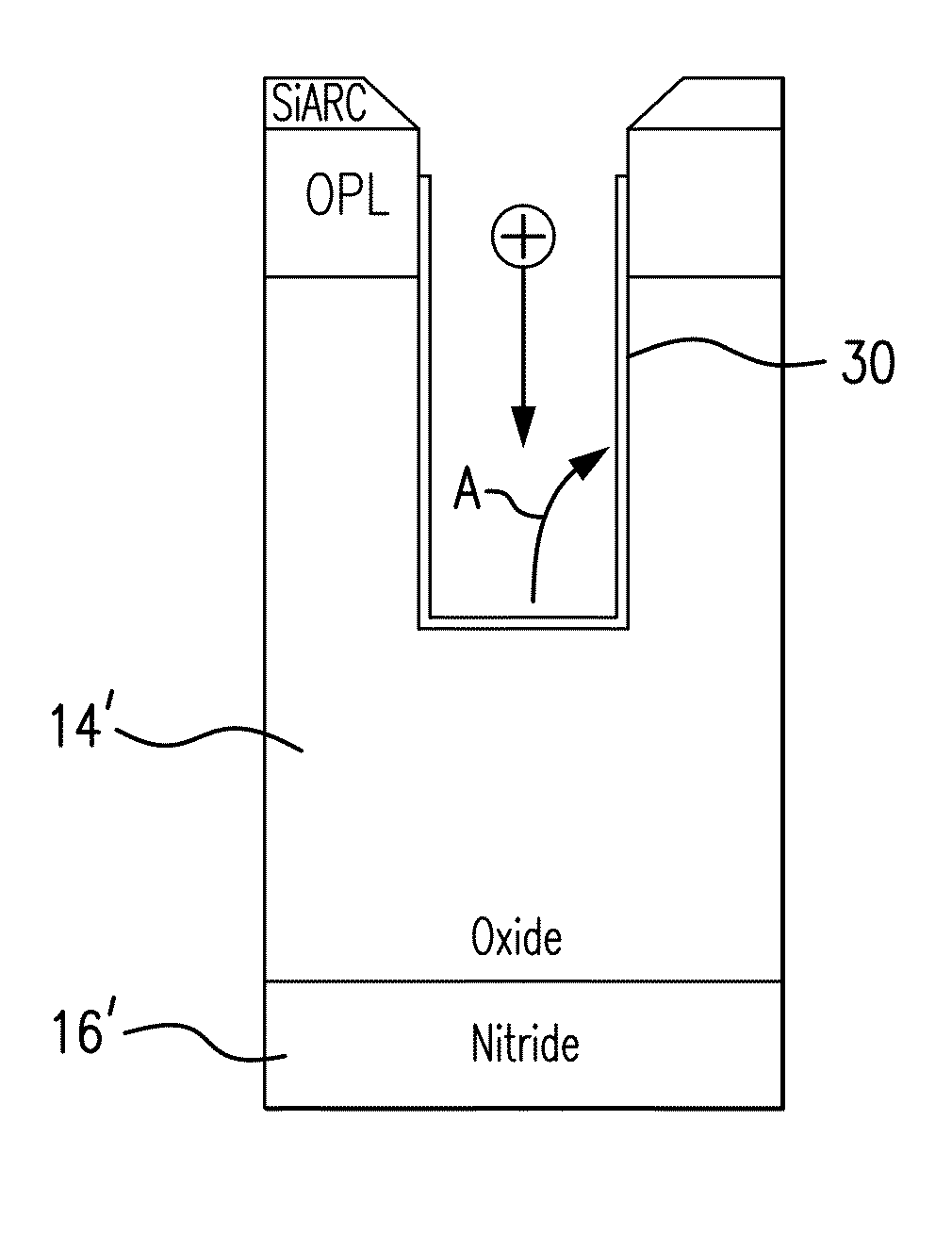

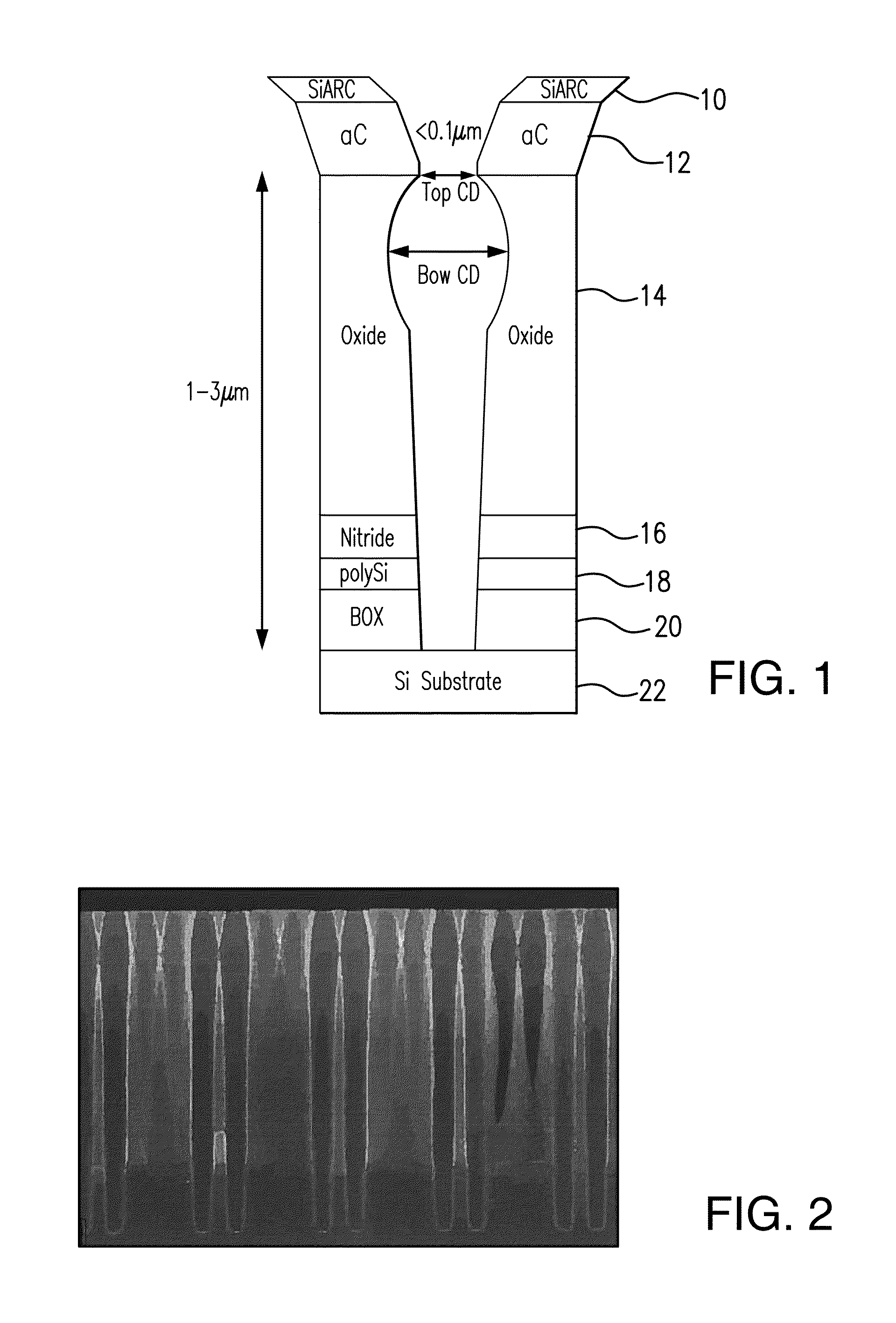

Reducing bowing bias in etching an oxide layer

ActiveUS20140295668A1Decreases bowing profileIncrease sidewall passivationSemiconductor/solid-state device manufacturingCapacitorsAspect ratioEtching

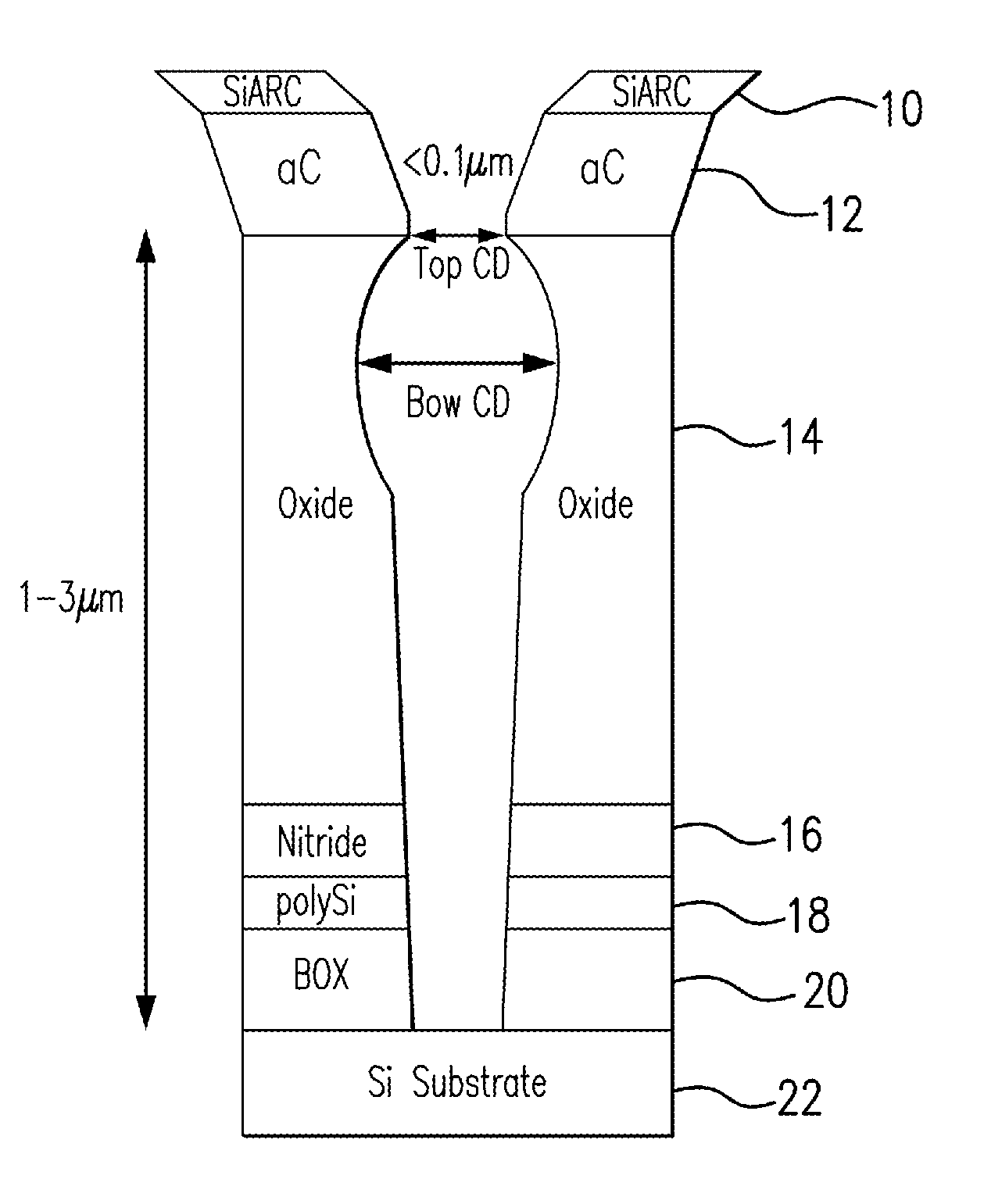

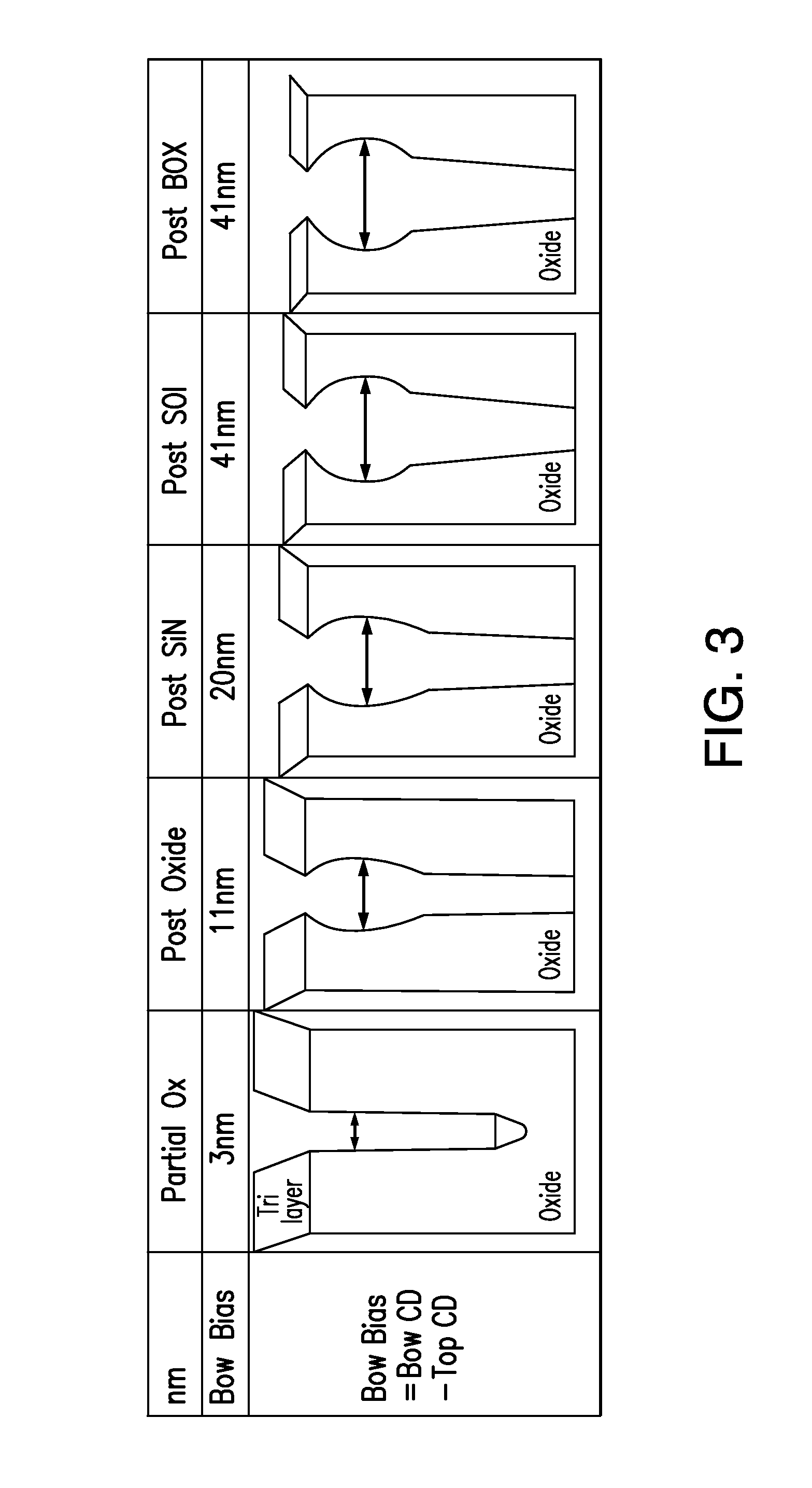

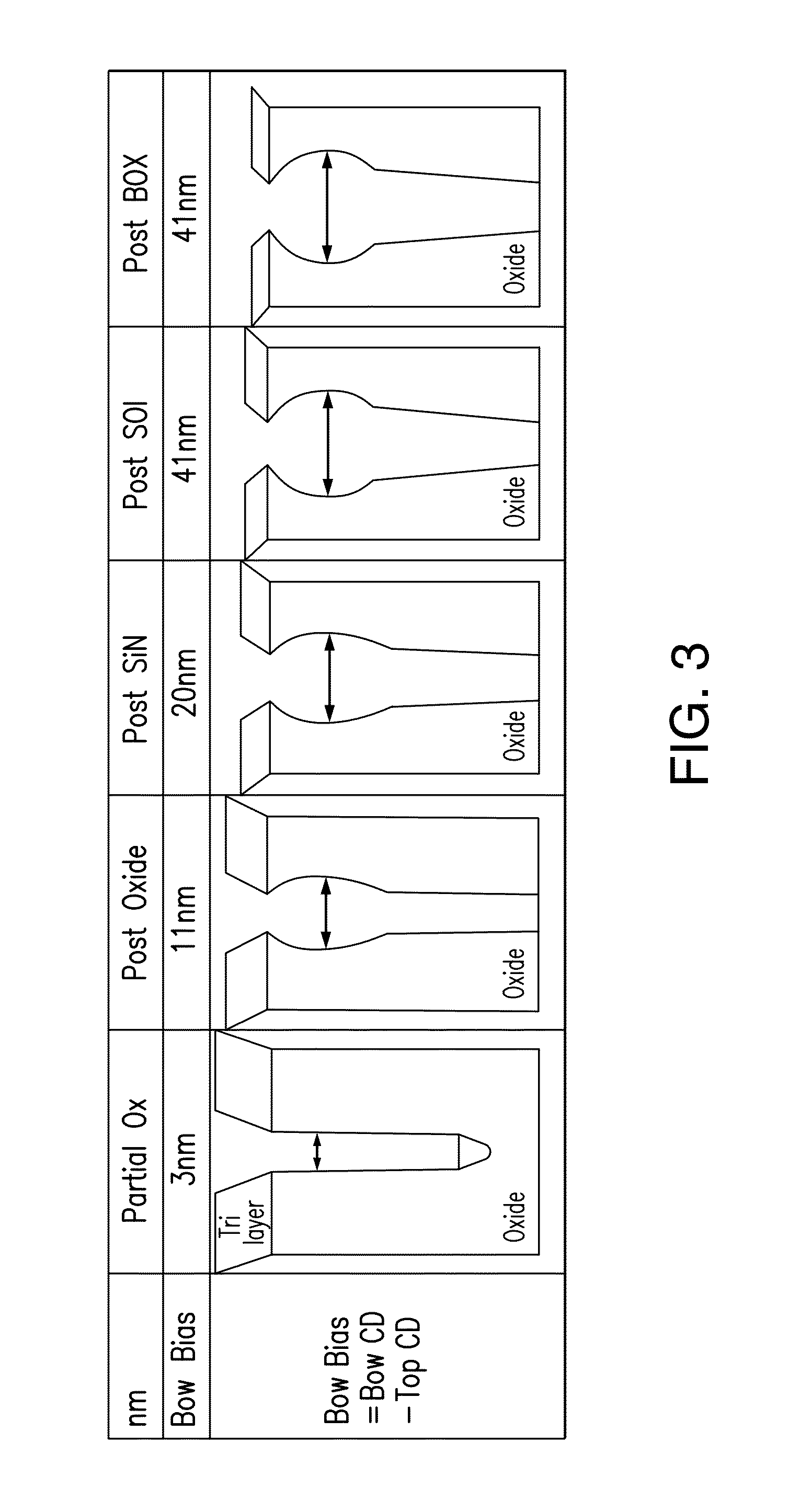

An etching method in which bowing or lateral etching is reduced or minimized, particularly with respect to bowing which can occur in etching of an oxide layer in high aspect ratio structures. It has been recognized that such bowing typically occurs in the upper portion of the oxide layer in terms of its location, but that the timing at which the bowing occurs is during the etching of the lower regions of the oxide layer and also during etching of a poly-Si or SOI layer located under the oxide layer. In a preferred form, a thicker passivation layer is formed in the upper region of the oxide layer and a thinner passivation layer is formed when etching the lower portion of the oxide layer or deeper in the etch trench. As a result, reduction in the passivation layer in the upper region which can occur during etching of the lower or deeper region of the trench can be accommodated by the increased thickness passivation layer. In addition, the bowing can be additionally reduced by accelerating the poly-Si or SOI etch, for example, by poly-Si simultaneously using both argon and nitrogen during the etch.

Owner:TOKYO ELECTRON LTD

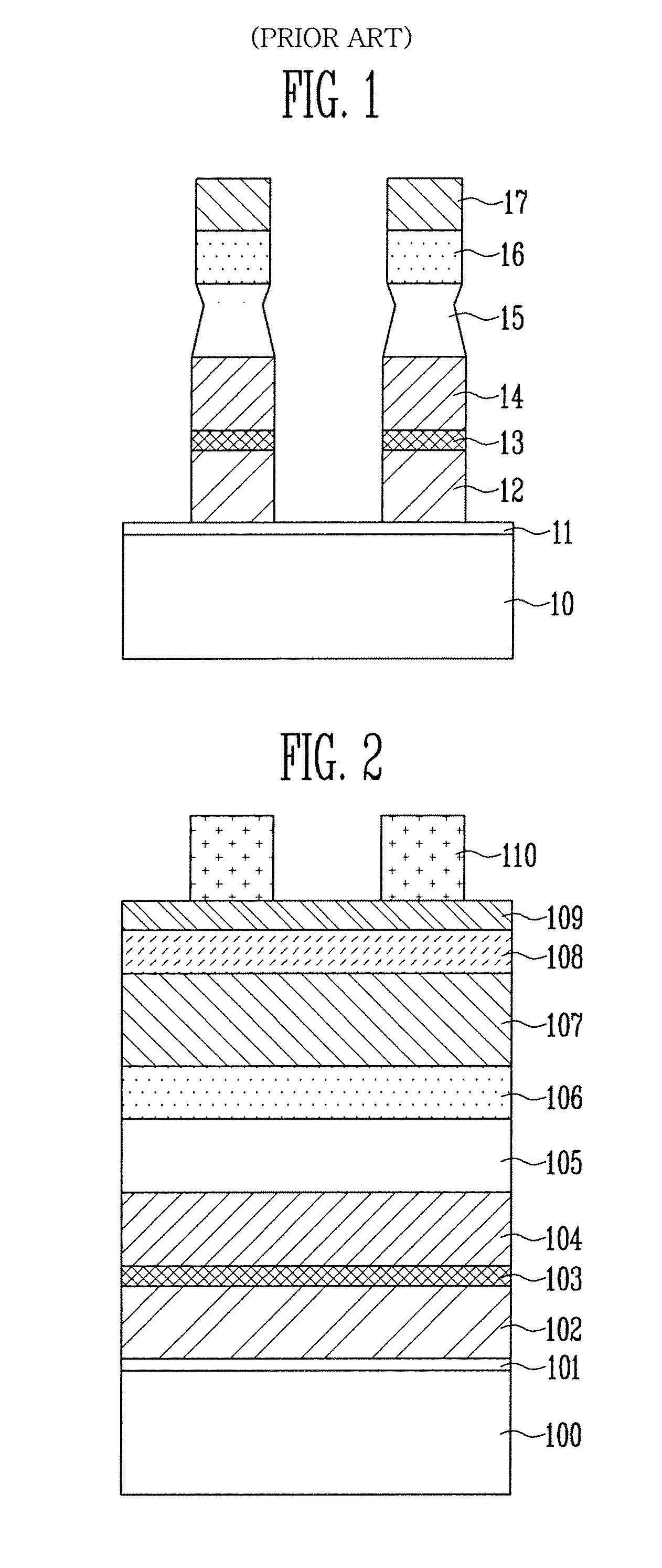

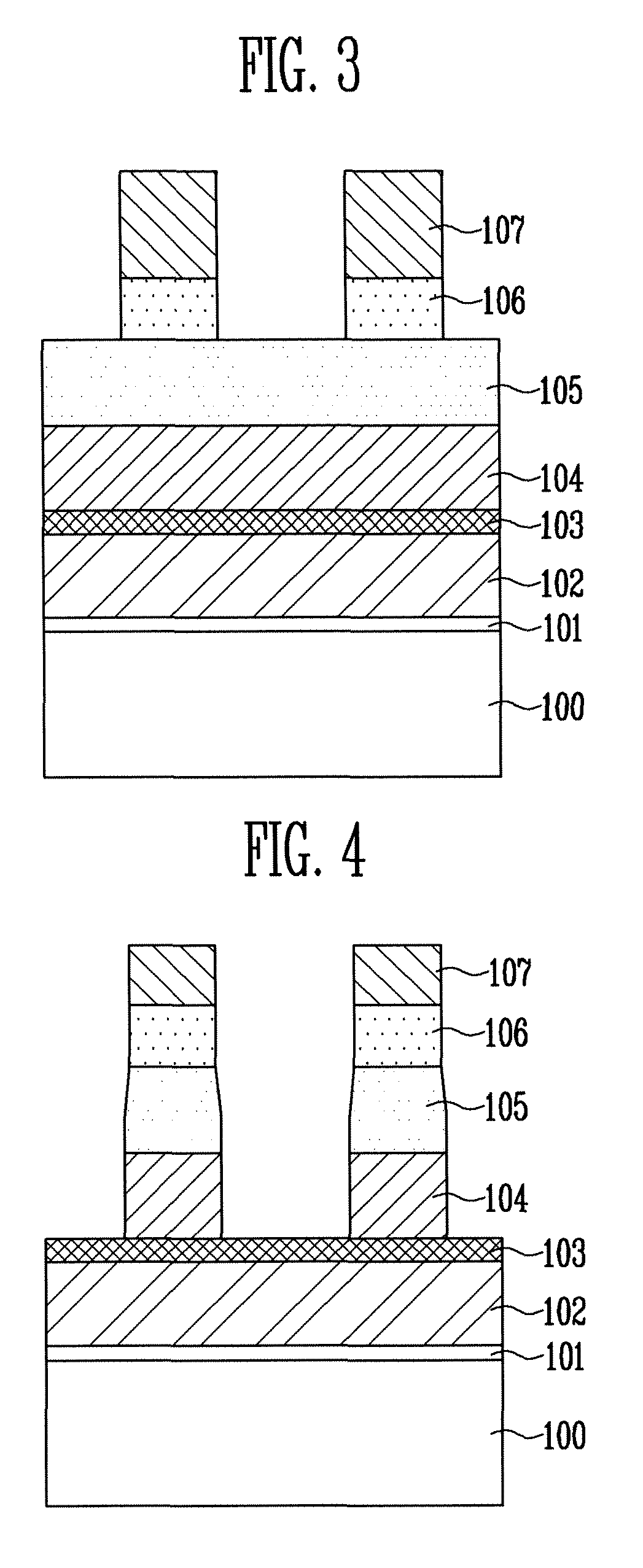

Method of forming gate pattern of flash memory device including over etch with argon

InactiveUS7741203B2Improve featuresIncrease heightSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsMetal electrodes

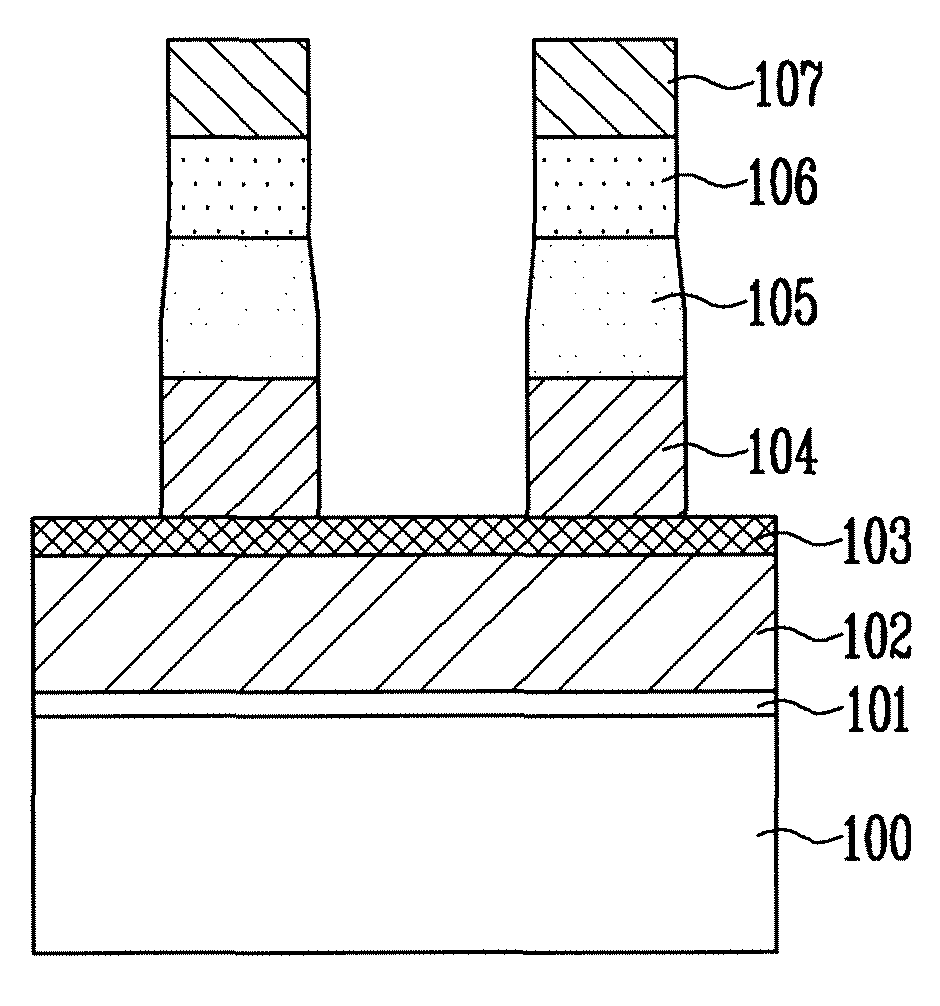

A method of forming a gate pattern of a flash memory device may include forming a tunnel dielectric layer, a conductive layer for a floating gate, a dielectric layer, a conductive layer for a control gate, a metal electrode layer, and a hard mask film over a semiconductor substrate. The metal electrode layer may be etched such that a positive slope of an upper sidewall may be formed larger than a positive slope of a lower sidewall of the metal electrode layer. The conductive layer for the control gate, the dielectric layer, and the conductive layer for the floating gate may then be etched. High molecular weight argon gas, for example, may be used to improve an anisotropic etch characteristic of plasma. Over etch of a metal electrode layer may be decreased to reduce a bowing profile. Resistance of word lines can be decreased and electrical properties can be improved.

Owner:SK HYNIX INC

Reducing bowing bias in etching an oxide layer

ActiveUS9165785B2Decreases bowing profilePromote passivationSolid-state devicesSemiconductor/solid-state device manufacturingEtchingNitrogen

Owner:TOKYO ELECTRON LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com