Method for processing food product

a technology of food products and rotary presses, which is applied in the field of rotary presses, can solve the problems of poor heat transfer and uneven heating, the cost of bigger and more powerful pumps and other equipment needed to deliver greater flow rates, and the failure to test the greater pressure and flow rate of directed water flows, etc., to achieve the effect of increasing the amount of food products, increasing the flow rate and/or the flow rate of higher pressure directed flows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

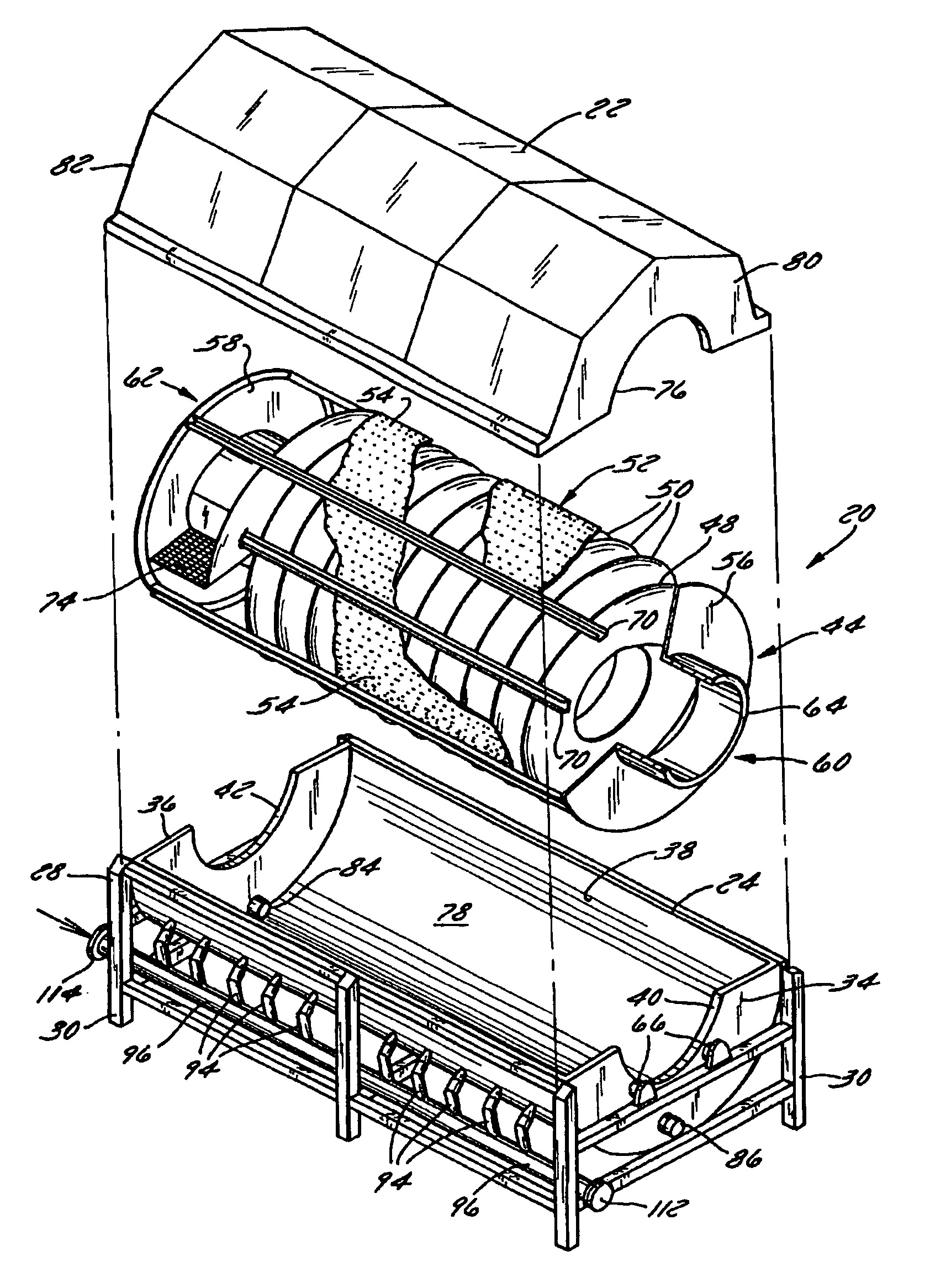

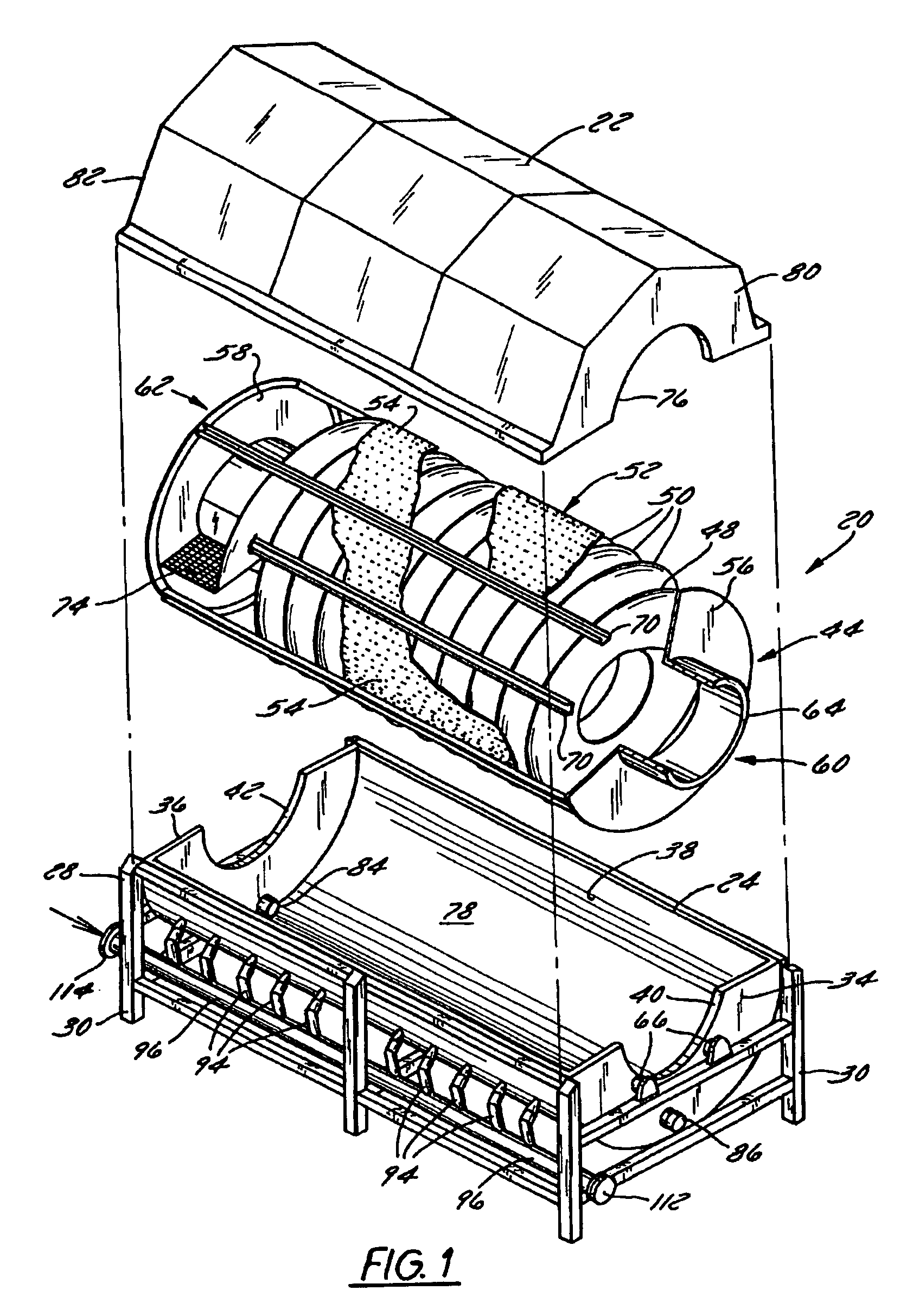

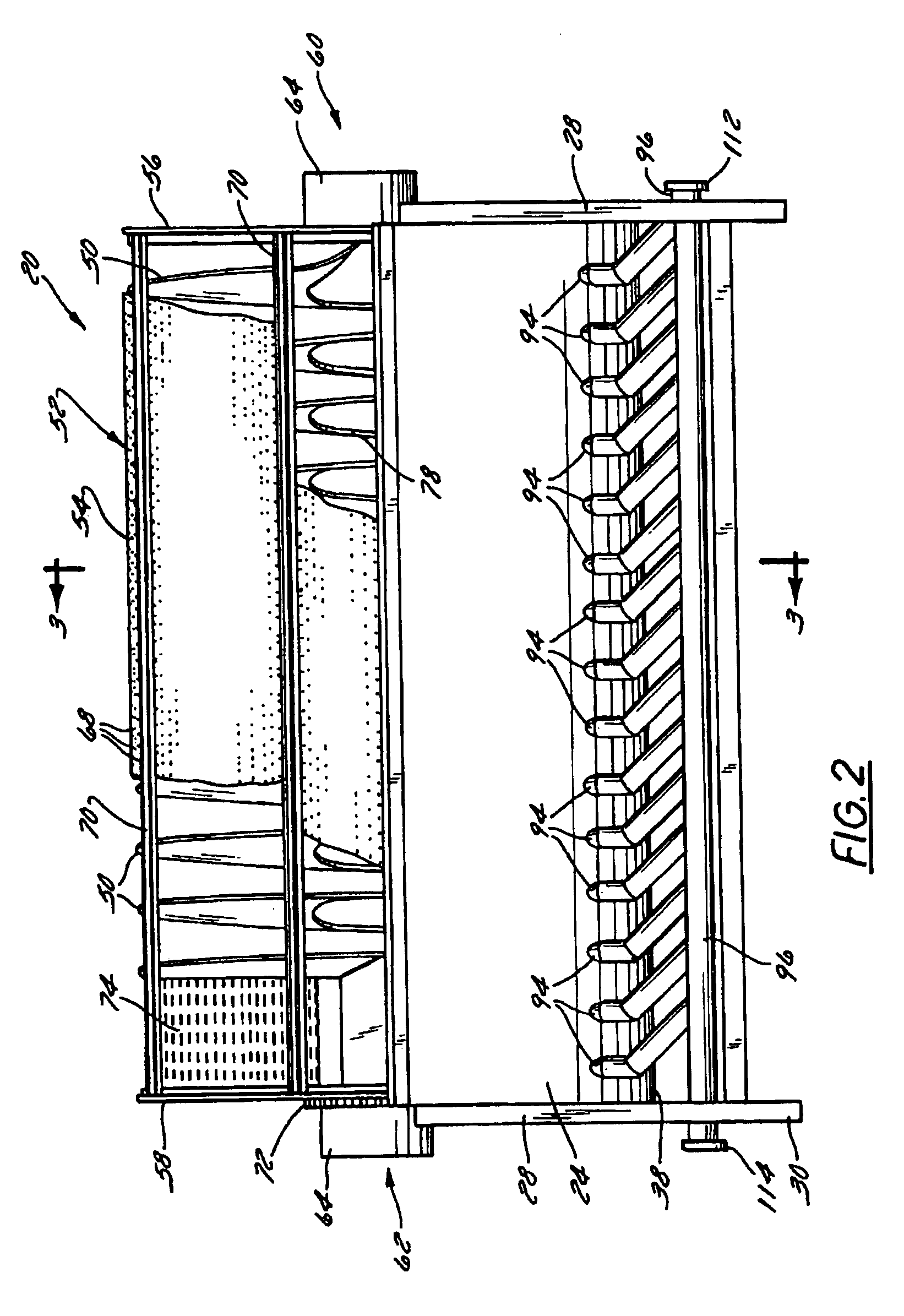

[0052]FIGS. 1-4 illustrate an exemplary rotary blancher 20 of this invention that utilizes directed flows of a fluid during operation to enhance heat transfer. As is shown more clearly in FIG. 6, the blancher 20 is comprised of a housing that includes a cover 22 that mates with a tank 24 that holds a heated fluid, that preferably is a liquid 26, which heats food products 32 during operation. The tank 24 is supported by a frame 28 that has legs 30, which rest on the floor or ground.

[0053]The tank 24, preferably made of stainless steel or another material suitable for food processing applications, has an inlet endwall 34 and an outlet endwall 36. The endwalls 34 and 36 are joined to a tank underside 38 that defines the bottom and lengthwise sides of the tank 24. The tank underside 38 may be a single, continuous, curved plate running lengthwise between endwalls 34 and 36, or may be made of several long flat plates positioned side by side and angularly joined together to form a generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com