Two section blue laser diode with reduced output power droop

a laser diode and output power technology, applied in the field of blue laser diodes, can solve the problems of thermal fluctuations, particularly deleterious to maintaining constant optical power output, and the drop in the light output of algainn laser diodes, so as to reduce transient heating and reduce power consumption , the effect of light output drooping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]In the following detailed description, numeric ranges are provided for various aspects of the embodiments described. These recited ranges are to be treated as examples only, and are not intended to limit the scope of the claims hereof. In addition, a number of materials are identified as suitable for various facets of the embodiments. These recited materials are to be treated as exemplary, and are not intended to limit the scope of the claims hereof.

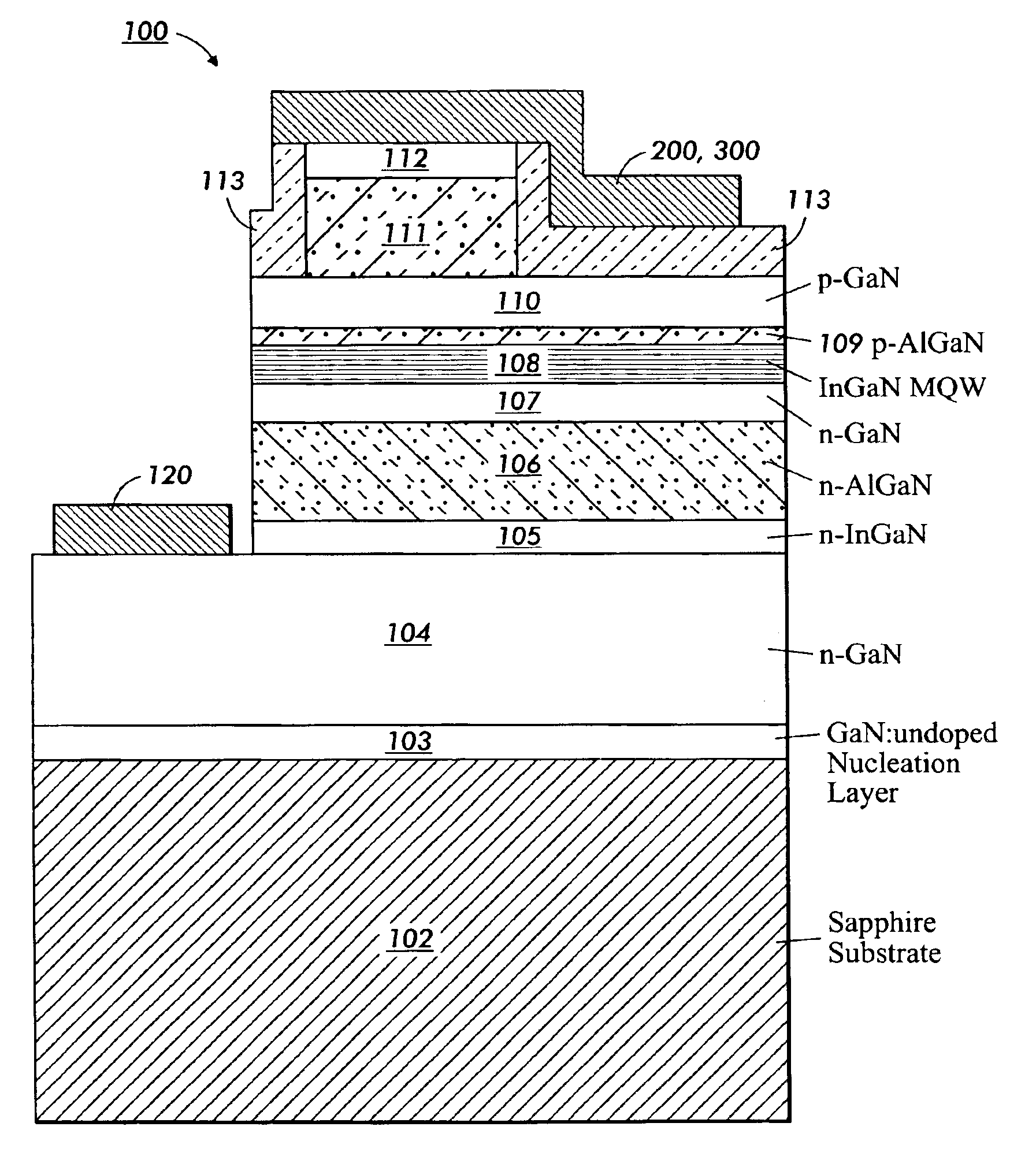

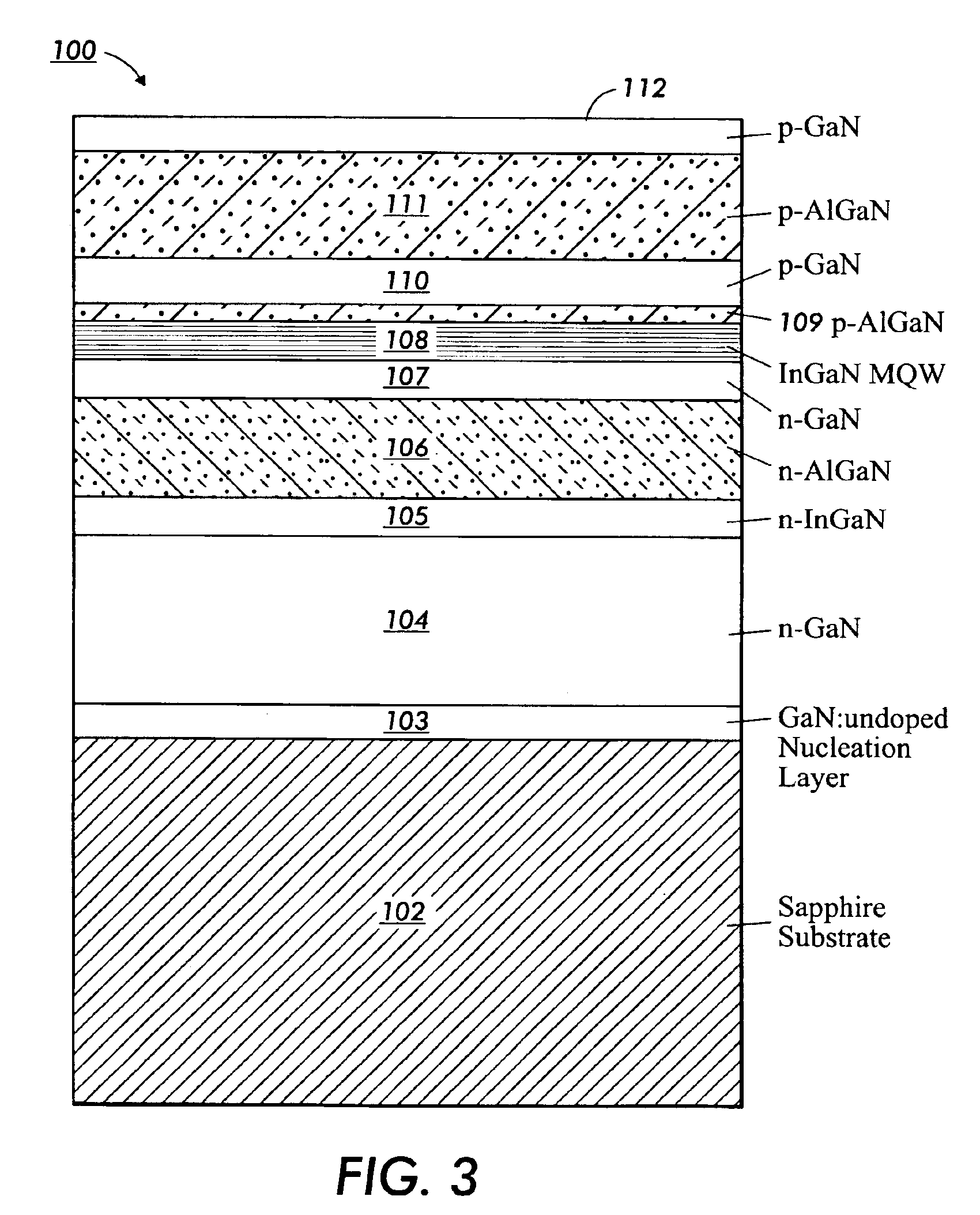

[0037]Reference is now made to FIG. 3 wherein is described the basic two section III-V nitride based semiconductor alloy diode laser 100 of the present invention. The semiconductor laser structure 100 has a C-face (0001) or A-face (1120) oriented sapphire (Al2O3) substrate 102 on which a succession of semiconductor layers is epitaxially deposited. The laser structure 100 includes a thin buffer layer 103, also known as a nucleation layer, formed on the sapphire substrate 102. The buffer layer 103 acts primarily as a wetting layer, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com