Confocal microscope apparatus and photographing apparatus for confocal microscope

a confocal microscope and microscope technology, applied in the field of confocal microscope apparatus and photographing apparatus, can solve the problems of low cost performance, poor balance between apparatus cost and performance, and often limited application to real-time observation, and achieve the effect of suppressing the noise of pinhole patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0047](First Embodiment)

[0048]The first embodiment will be described, where the present invention is applied to a confocal microscope apparatus including an erect microscope and a photography.

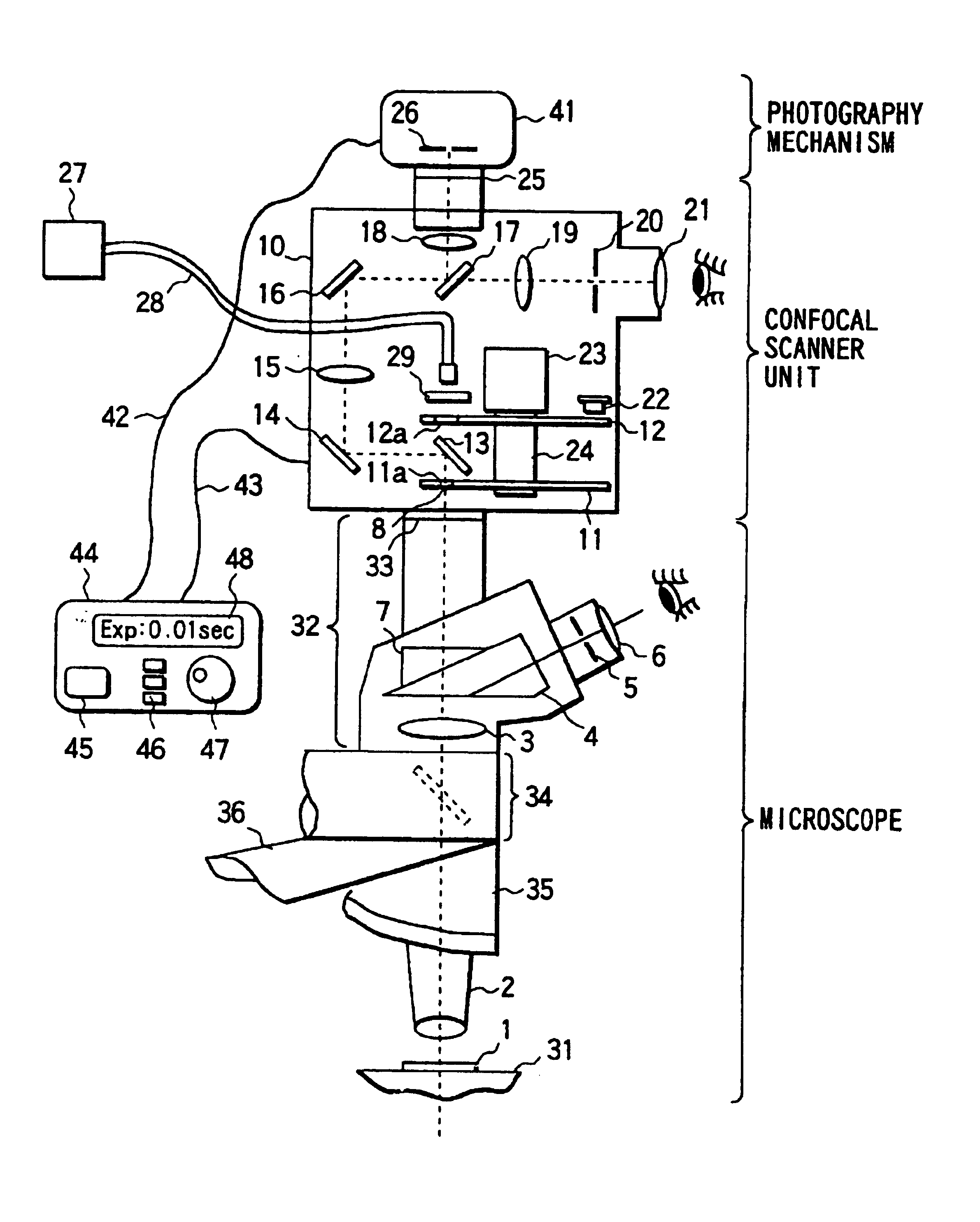

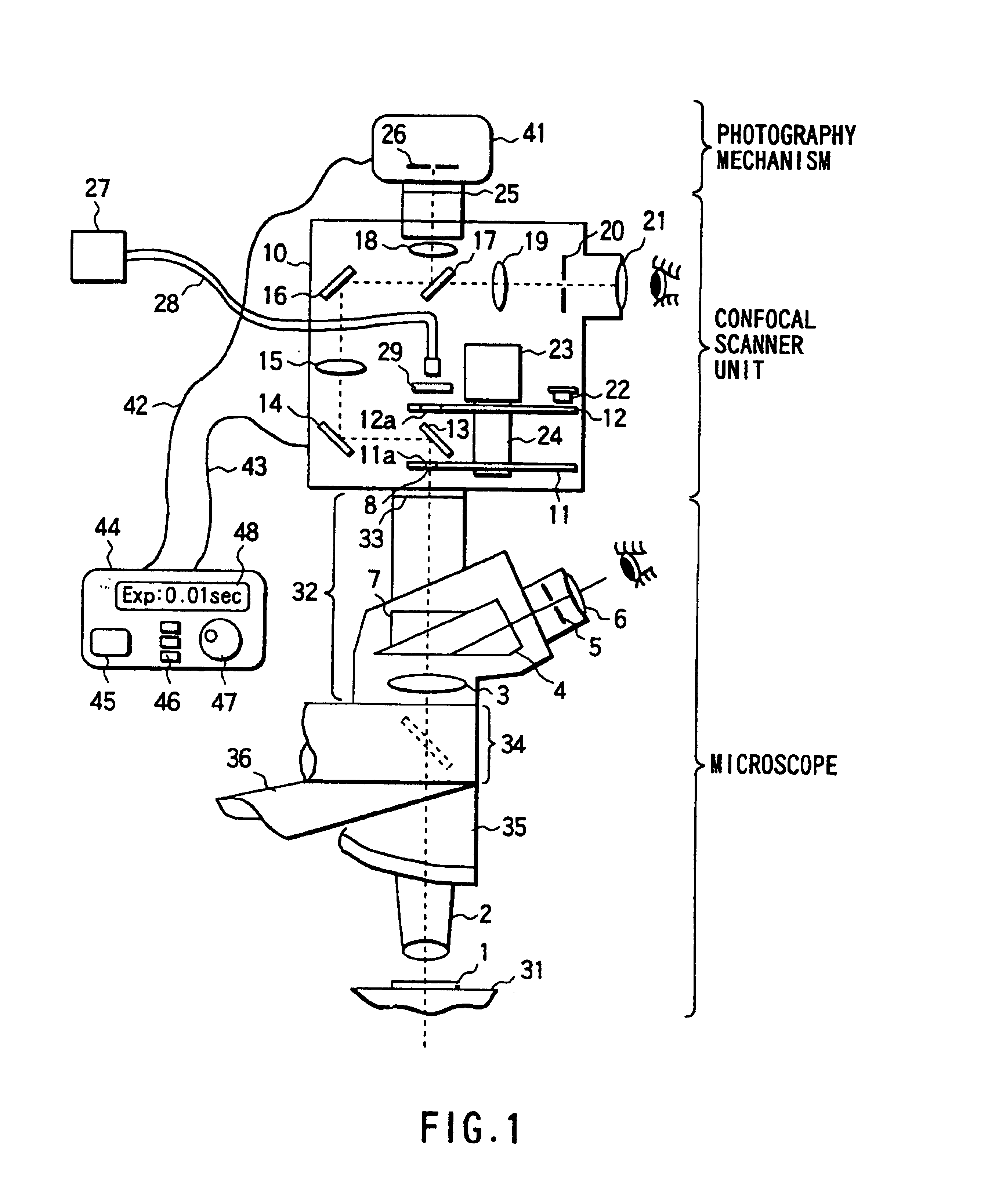

[0049]FIG. 1 shows the arrangement of the whole optical system of the confocal microscope apparatus. The optical system is made up of three parts, photography mechanism, confocal scanner unit 10, and microscope.

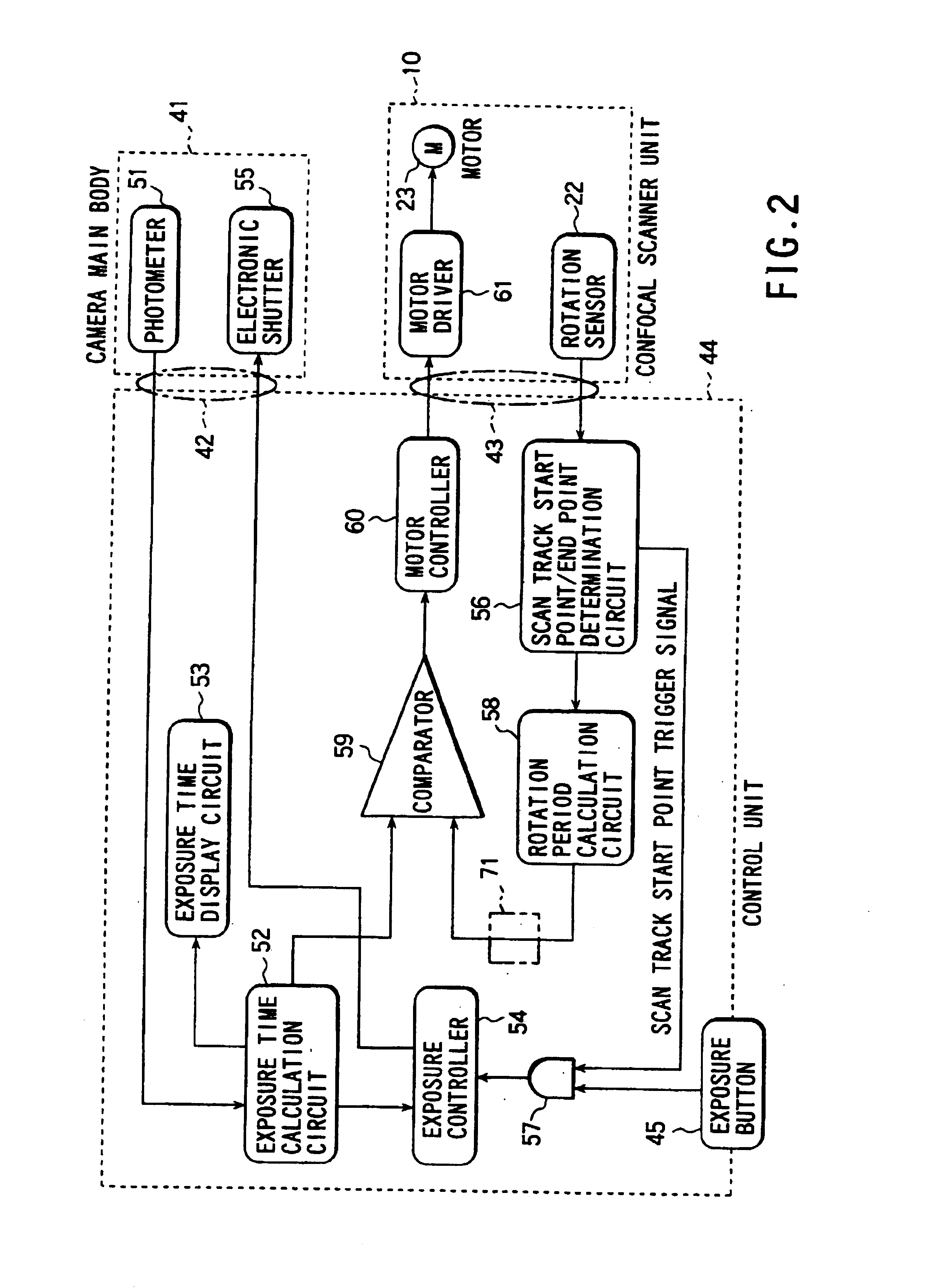

[0050]The microscope is an erect microscope having a triple-lens barrel 32 with a photographing optical path. FIG. 1 shows an only upper observation optical system from the upper surface of a stage 31. The photography mechanism contains a camera main body 41 and a control unit 44. The camera main body 41 and control unit 44 are connected by a cable 42 in two ways. The control unit 44 and confocal scanner unit 10 are connected by a cable 43 in two ways.

[0051]In the triple-lens barrel 32, a 30° prism 4 and a cylindrical prism 7 are selectively exchangeably inserted in the optical path on a...

second embodiment

[0071](Second Embodiment)

[0072]The second embodiment will be described, where the present invention is applied to a confocal microscope apparatus including an erect microscope and a photography.

[0073]The arrangement of an optical system in the second embodiment is the same as that described with reference to FIG. 1.

[0074]FIG. 3 is a block diagram showing the arrangement of an electronic circuit according to the second embodiment provided to the control unit 44, camera main body 41, and confocal scanner unit 10. The electronic circuit shown in FIG. 3 is basically the same as that shown in FIG. 2 except for the following difference.

[0075]The second embodiment is arranged in consideration of a case where the user observes a specimen with the naked eye via an eyepiece lens 21 without using any camera main body 41, and a case where a video camera device (not shown) is mounted instead of the camera main body 41. In mounting the video camera device, a video sync signal equivalent to a vert...

third embodiment

[0085](Third Embodiment)

[0086]The third embodiment will be described, where the present invention is applied to a confocal microscope apparatus including an erect microscope and a photography.

[0087]The arrangement of an optical system in the third embodiment is the same as that described with reference to FIG. 1.

[0088]FIG. 4 is a block diagram showing the arrangement of an electronic circuit according to the third embodiment provided to the control unit 44, camera main body 41, and confocal scanner unit 10. The electronic circuit shown in FIG. 4 is basically the same as that shown in FIG. 2 except for the following difference.

[0089]In the third embodiment, a comparator 59′ receives a rotational period limit signal representing the upper limit of the rotational period of the motor 23 from a rotational speed reference circuit 65. A laser intensity controller 66 which has received a signal outputted from the comparator 59′ appropriately outputs a laser intensity control signal to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com