Conveyor and conveyor belt cleaning sprocket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

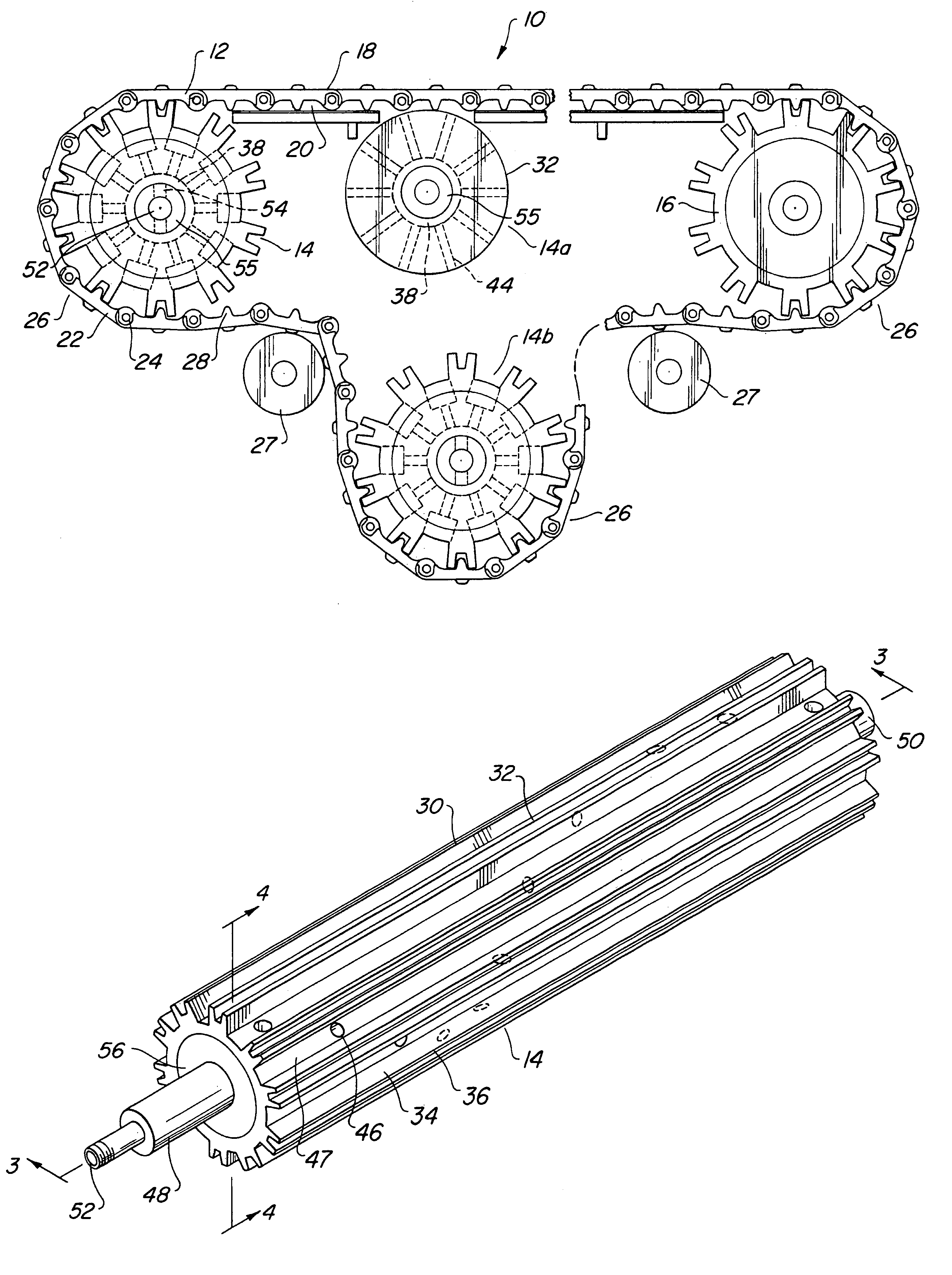

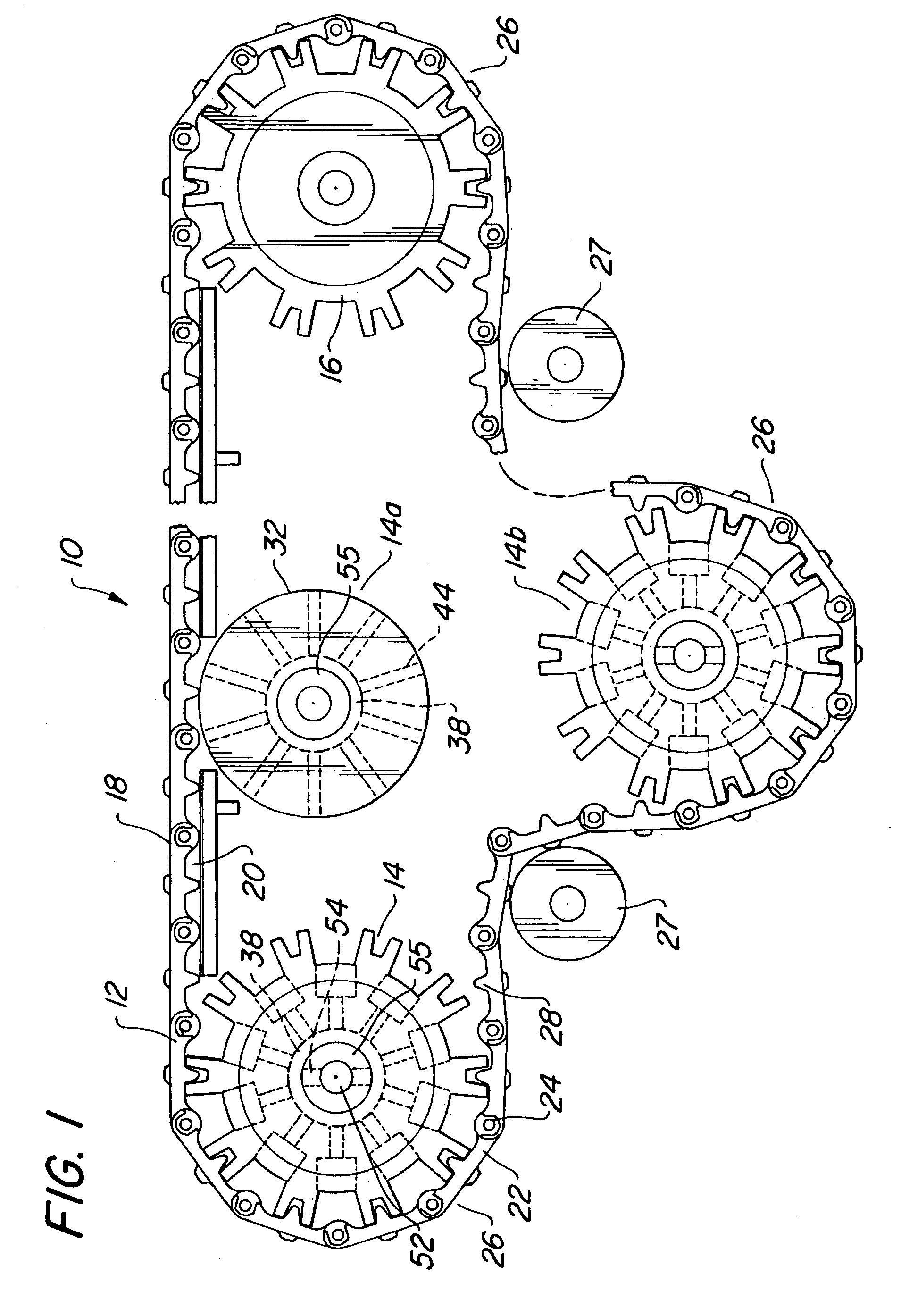

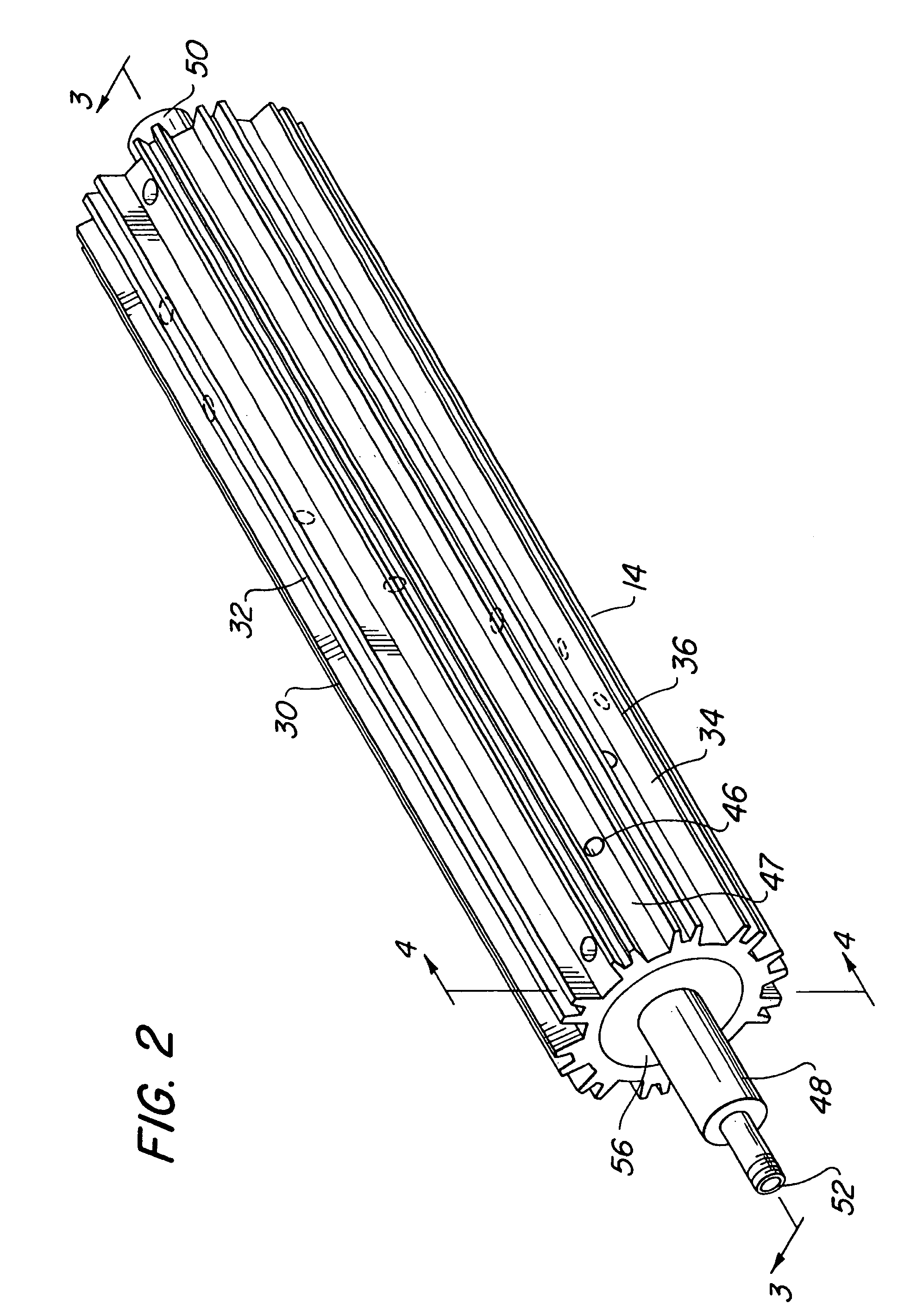

[0027]FIG. 1 shows an endless conveyor 10 according to the invention, the conveyor having an endless belt 12 suspended between two rotatably mounted sprockets 14 and 16. Belt 12 has an outwardly facing surface 18 on which the items to be transported by the belt are supported and an inwardly facing surface 20 opposite the surface 18 and engaging sprockets 14 and 16. Belt 12 is preferably made of a plurality of segments 22 arranged side by side and hingedly connected to one another by hinge pins 24 allowing segments 22 to pivot relative to one another when traversing around sprockets 14, 14b and 16 as shown at positions 26 in FIG. 1. Preferably, segments 22 have mating teeth 28 projecting from the inwardly facing surface 20 to engage teeth on sprockets 14, 14b and 16 described below. As noted above, sprocket 14 could be an idler sprocket, a driver sprocket, a support roller such as 14a in FIG. 1, positioned to engage inwardly facing surface 20 of belt 12 at intermediate points along i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com