Ball and socket bearing for artificial joint

a technology of artificial joints and bearings, applied in the field of artificial joints, can solve the problems of patient immobility, difficult alignment of subsequent reconstructions, and inability to meet patient needs,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

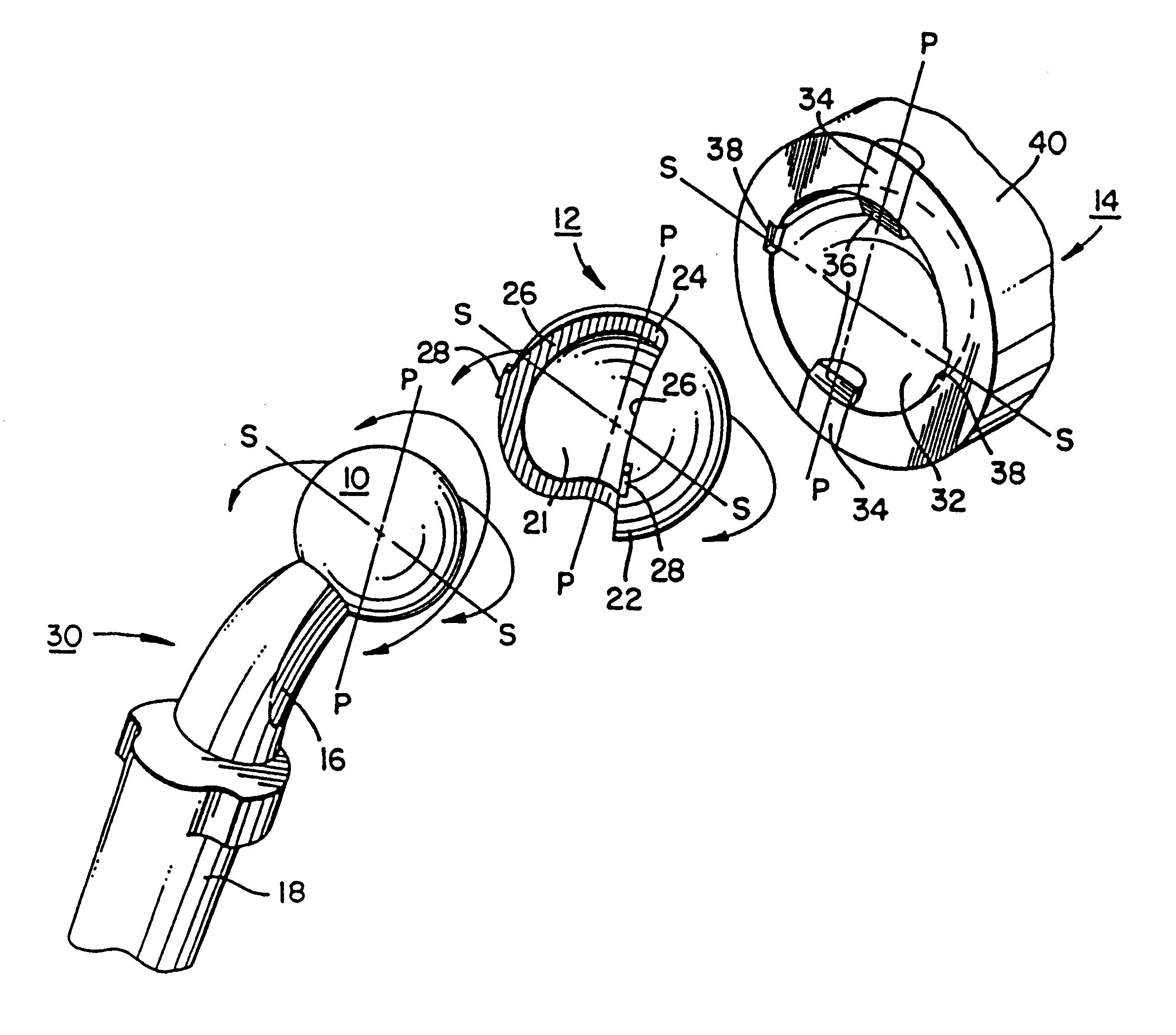

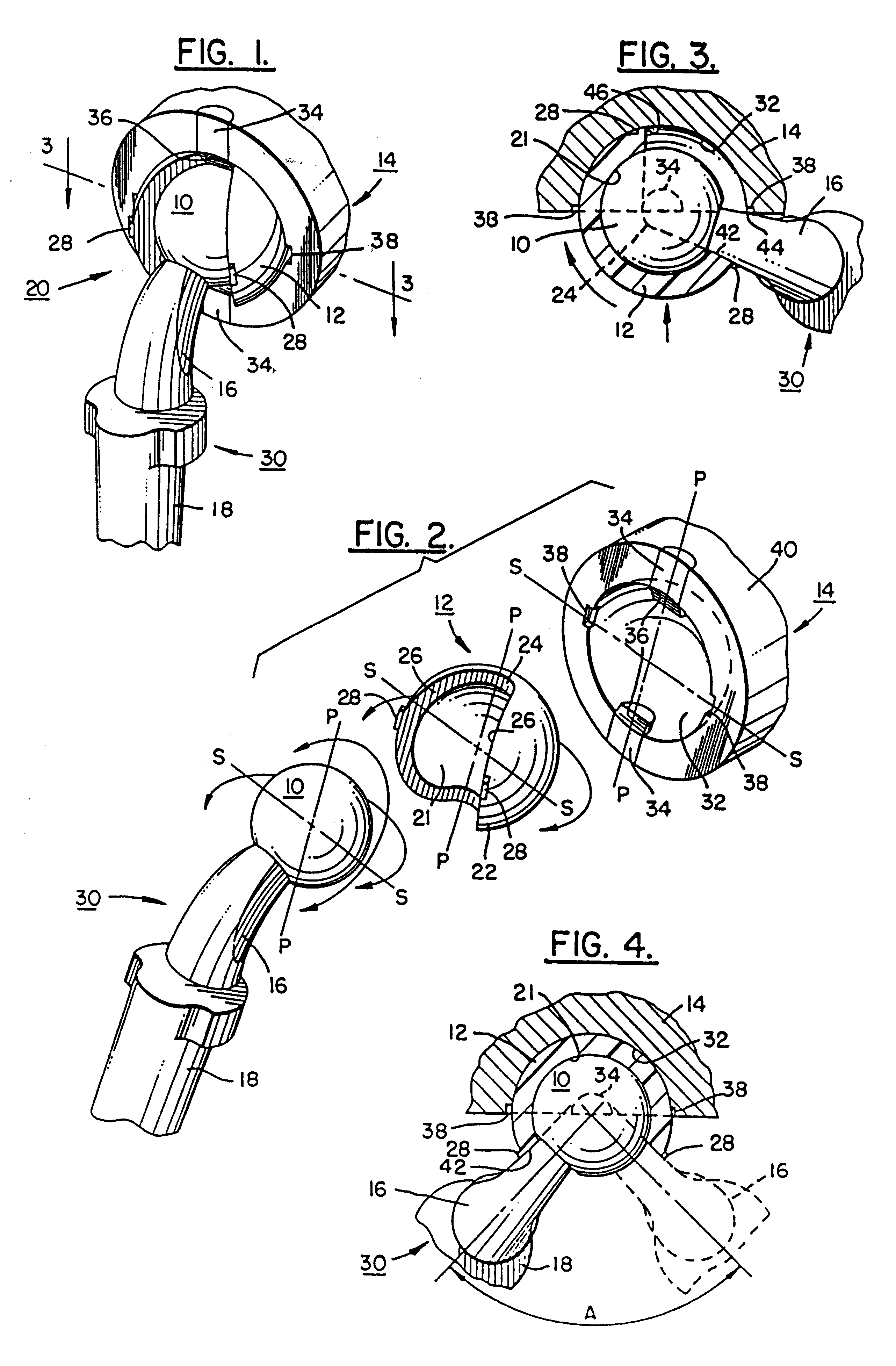

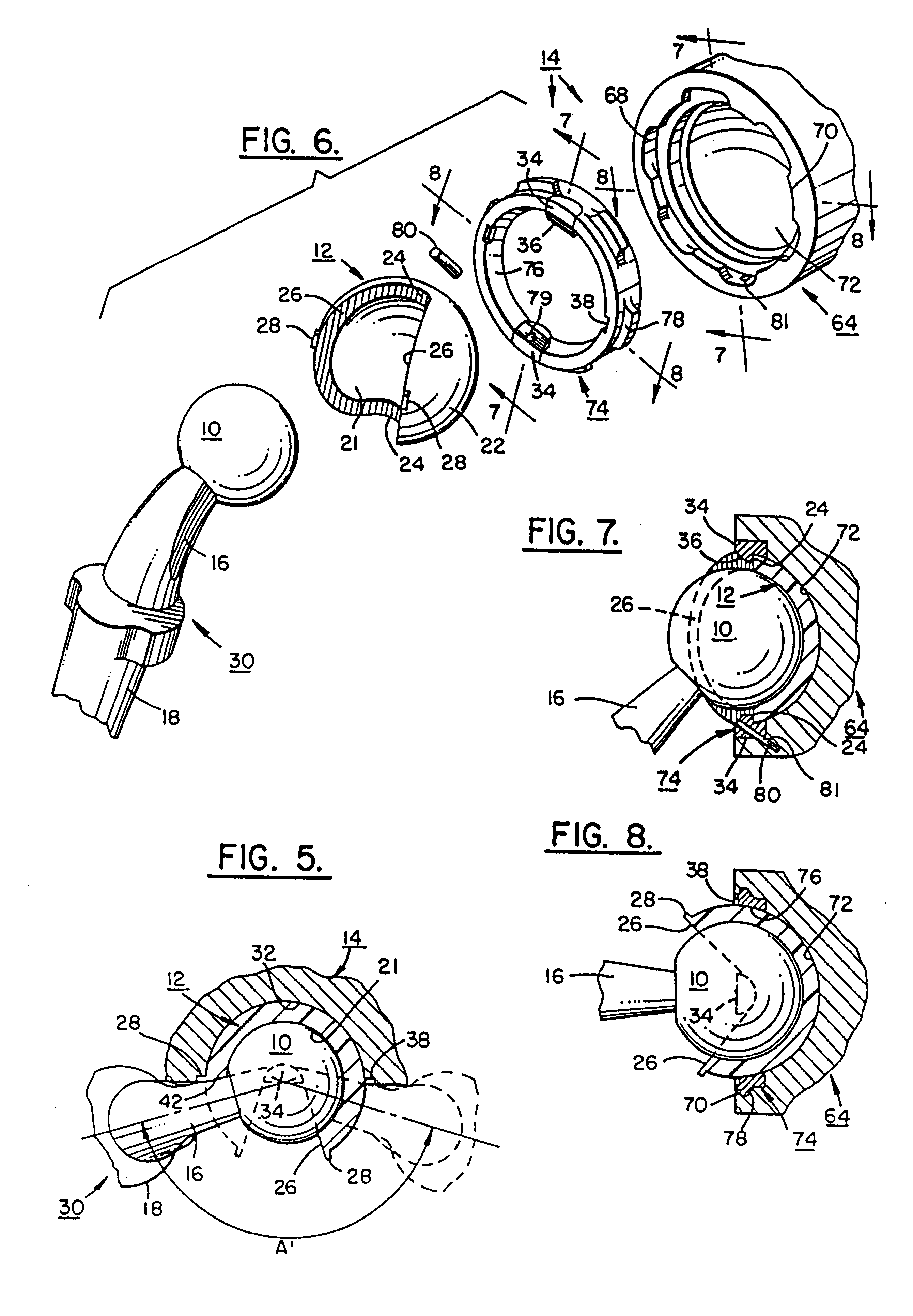

With reference now to the drawings, wherein like reference characters designate like or corresponding parts throughout the several views, there is shown in FIG. 1 an assembly 20 of ball or sphere 10, socket bearing 12 and cup 14 for a prosthetic joint. The neck 16 of arm 30 is intermediate ball 10 and stem or shaft 18, which stem or shaft is fixed to, for example, the femur bone at the time of implant surgery.

FIG. 2 shows in more detail socket bearing 12 of assembly 20. The preferred material for bearing 12 is ultra-high molecular weight polyethylene (UHMWPE). Inner spherical bearing surface 21 of bearing 12 is concentric with outer spherical bearing surface 22. Cylindrical surfaces 24 are coaxial with each other and with the center of spherical surfaces 21 and 22 and are tangent to surfaces 26. Small barb-shaped protuberances 28 serve a detent function described below.

In the plane passing through the lines P--P in FIG. 2, socket bearing 12 encompasses less than one half of ball 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com