Process for recycling and purifying condensate from a hydrocarbon or alcohol synthesis process

a technology of condensate, which is applied in the field of recycling condensate from a hydrocarbon or alcohol synthesis, can solve the problems of contaminated condensate having little or no commercial value, and the separation is not necessarily complete, so as to achieve easy and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention provides a process of purifying a condensate stream from a hydrocarbon or alcohol synthesis process, thereby eliminating the need for expensive water treatment steps. In doing so, a hot gaseous stream comprising contaminants, CH.sub.4, and steam is produced and used as feed gas to a synthesis gas generation process.

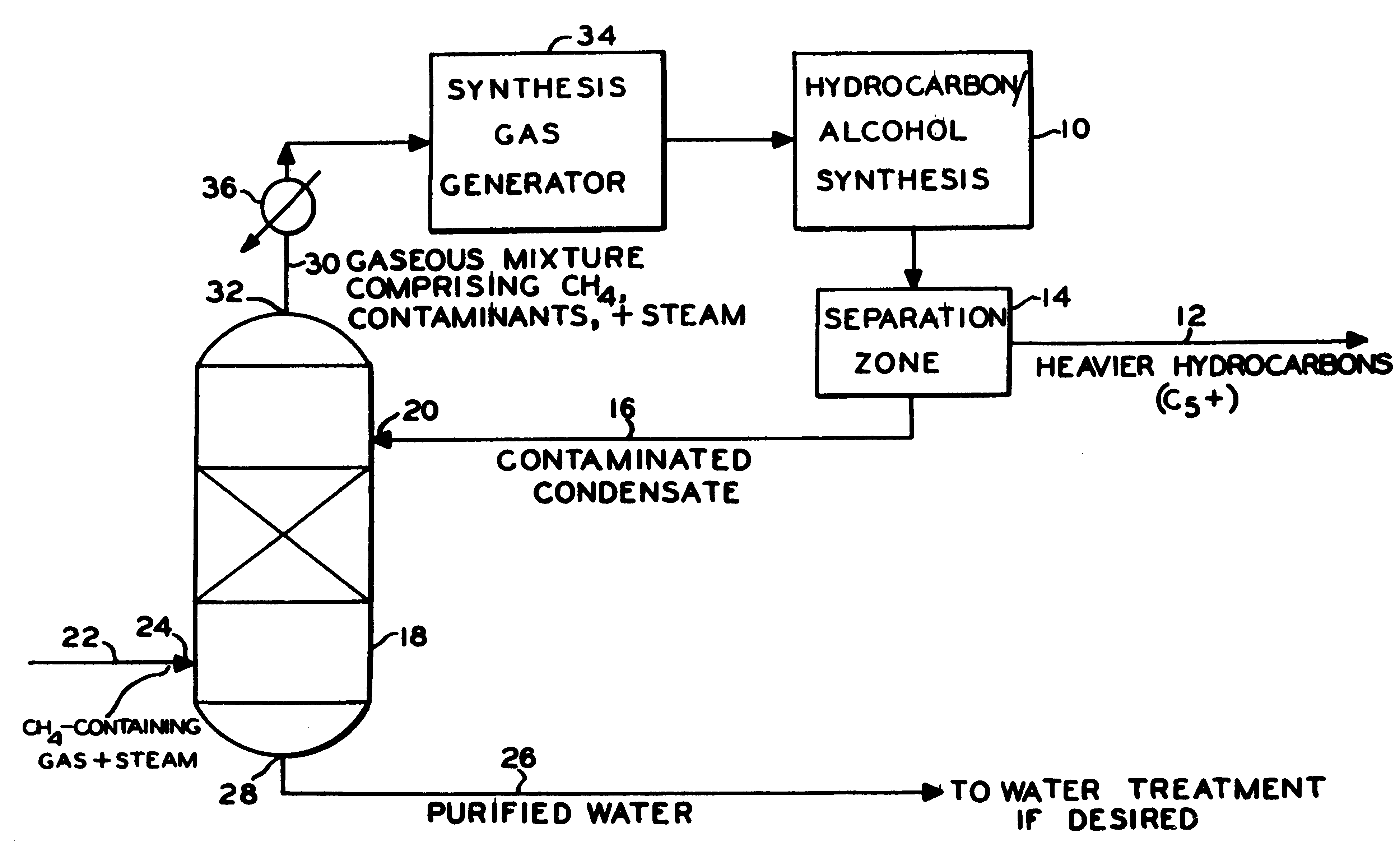

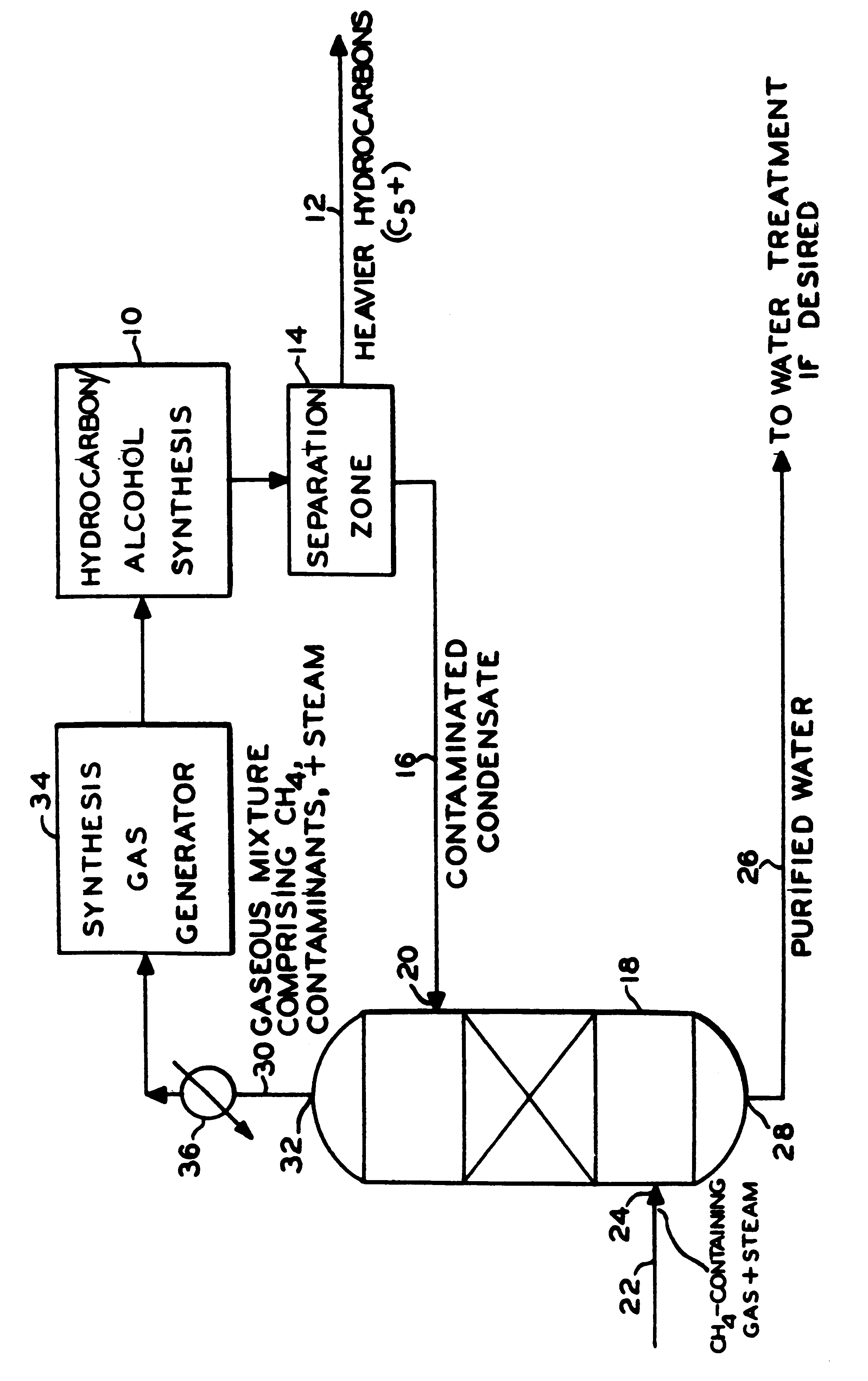

The condensate of the instant invention can come from a typical hydrocarbon synthesis process 10. The heavier hydrocarbons 12, preferably C.sub.5 +, are separated from the water phase or condensate by, for example, a sedimentation process 14. The remaining condensate 16, comprising predominately water and contaminants such as lower molecular weight hydrocarbons, alcohols, and other oxygenates. is passed to a vessel 18, preferably a sieved tray tower. A packed tower or any device that allows countercurrent vapor / liquid separation may also be used. The condensate enters the tower at or near the top at 20. A hot gaseous mixture comprising CH.sub.4 and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com