System and method for drying green woods

a technology for drying systems and green woods, applied in the field of systems for drying wood, can solve the problems of poor investment, distortion of woods, and inability to dry wood, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Hereinbelow, the present invention will be described in detail with reference to the accompanying drawing.

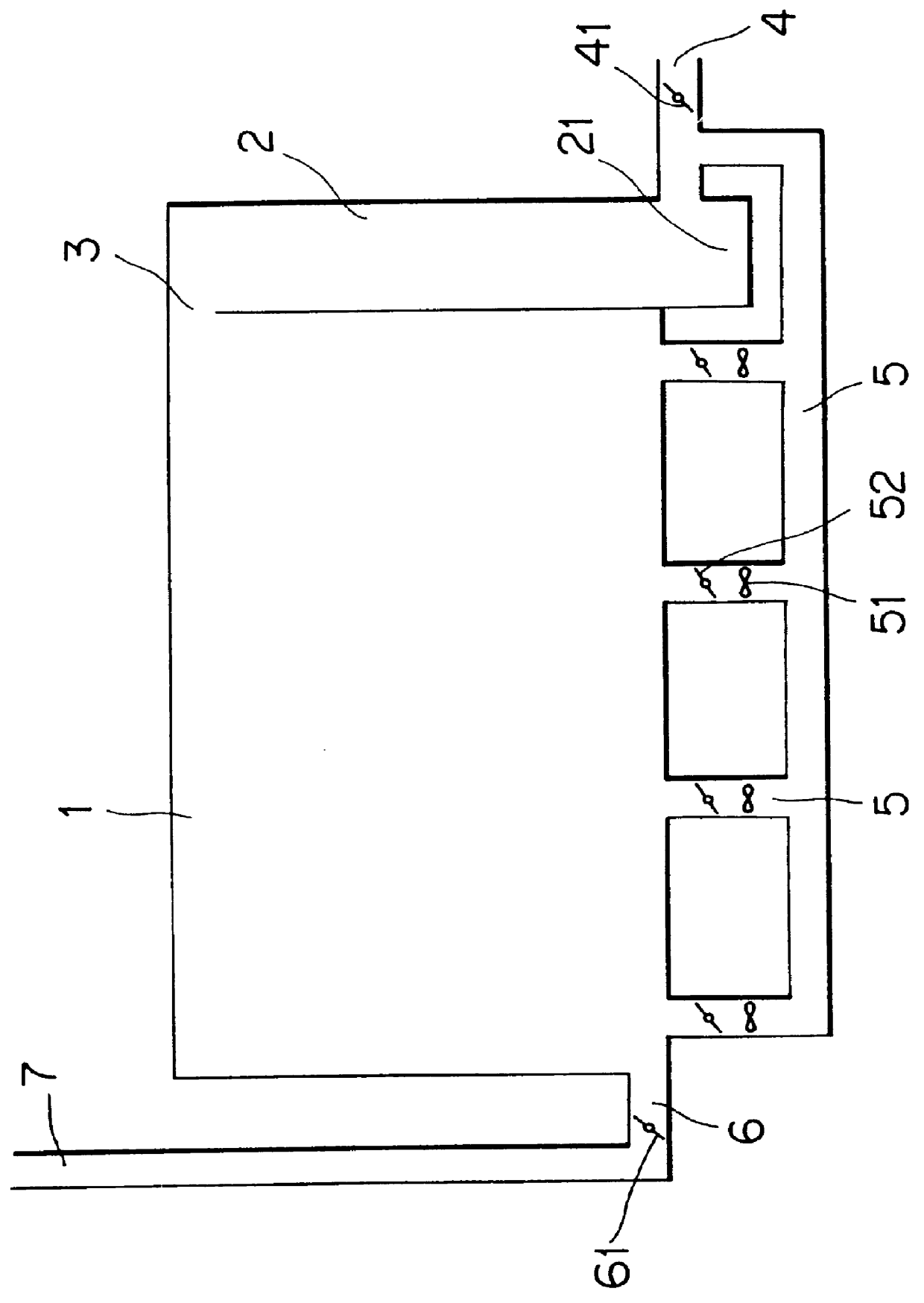

As shown in the drawing, in drying operation a of green wood (and the like), the wood is housed and piled up in a wood drying room 1. The room 1 is capable of being sealed, while so disposed as to be adjacent to a combustion-gas generator 2 an upper area of which is in communication with an upper area of the wood drying room 1 by means of a combustion-gas supplying passage 3.

A lower area of the combustion-gas generator 2 forms a combustion chamber 21 in which suitable fuels such as waste wood and the like are burned to produce a hot combustion gas. With the combustion chamber 21 of the combustion-gas generator 2 is connected an air-inlet conduit 4 for introducing fresh air into the combustion chamber 21.

Rotatably mounted in an opening-end portion of the air-inlet conduit 4 is a damper 41 for controlling the flow rate of fresh air introduced into the combustion chamber 21 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com