Sabot

a technology of sabots and composite petal parts, applied in the field of sabots, can solve the problems of inaccurate targeting of projectiles, torsional load on the entire sabot, and even safety problems, and achieve the effect of greatly reducing the torsional load on the composite petal of the sabo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

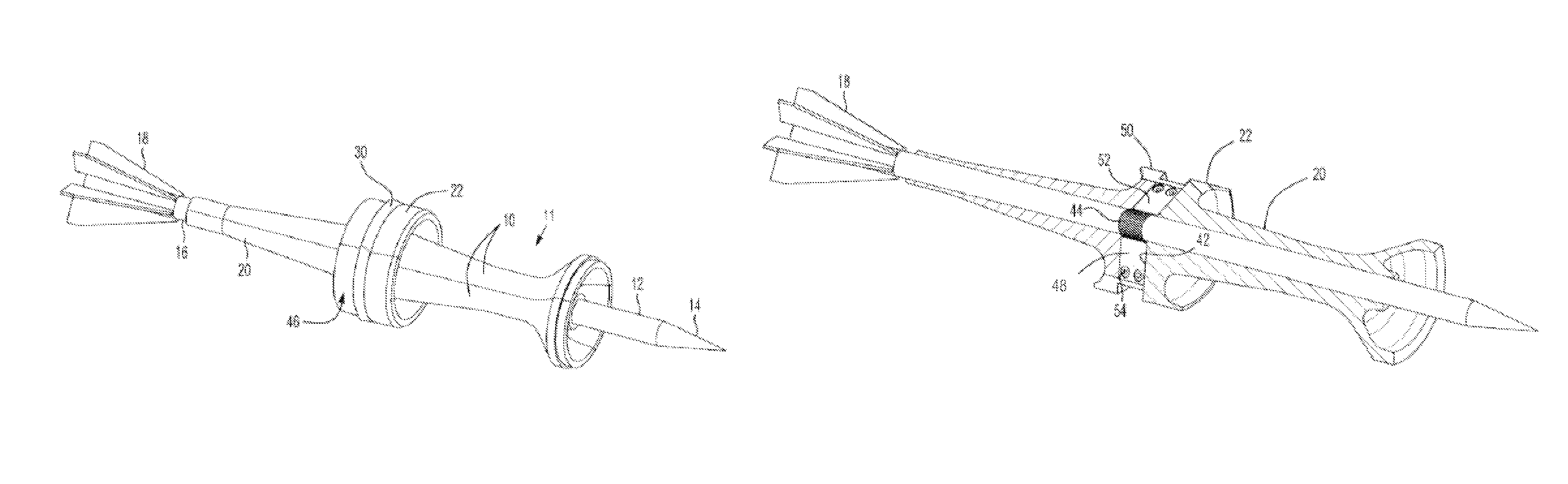

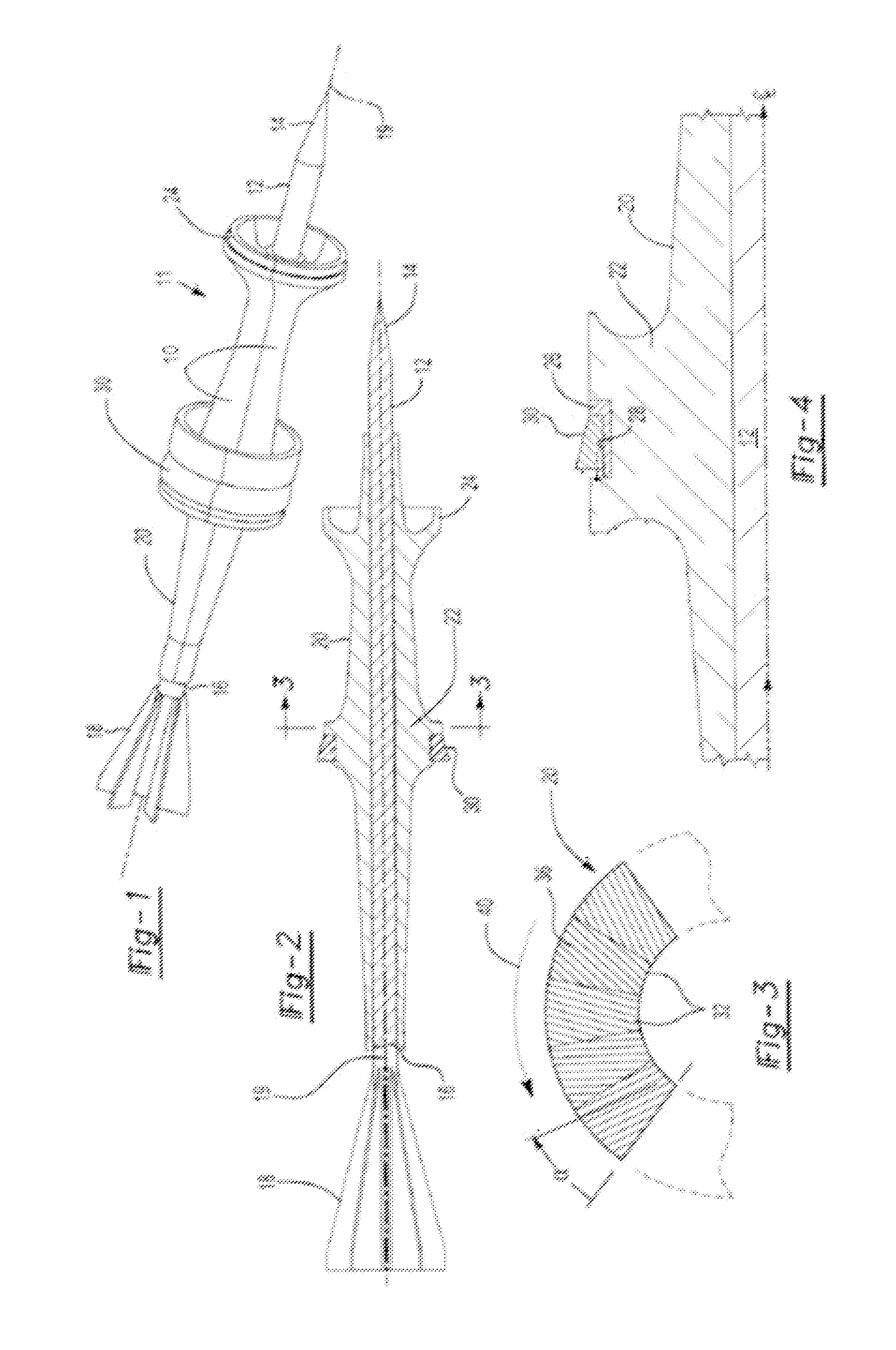

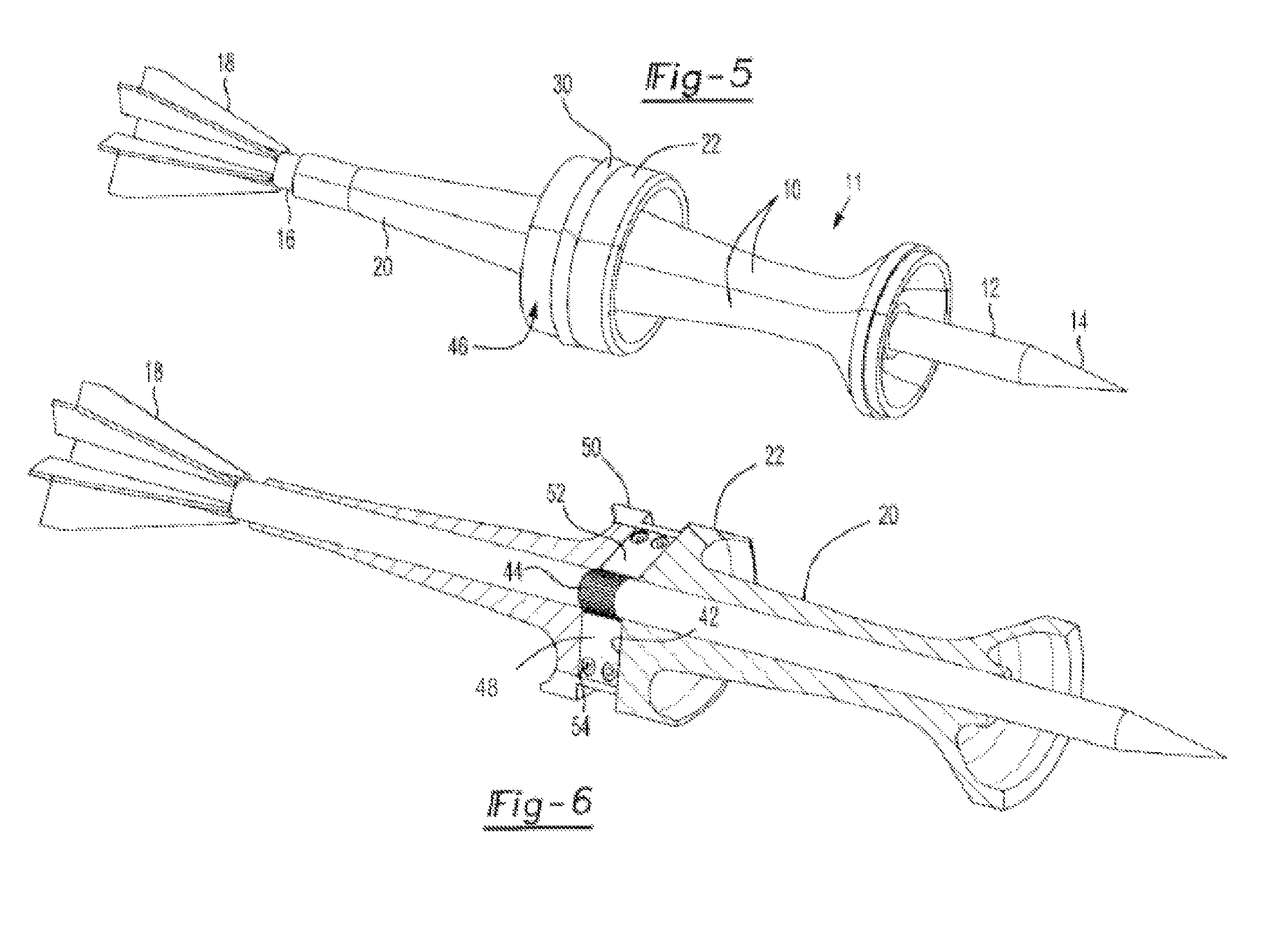

[0023]With reference first to FIGS. 1 and 2, a preferred embodiment of a sabot 10 according to the present invention is illustrated as a component of a launch package 11 consisting of a sabot 10, a sub-projectile 12 and a slipband 30. The launch package 11 includes an elongated projectile or penetrator 12 having an impact end 14 and a tail end 16. A fin set 18 is attached to the tail end 16 of the sub-projectile 12. The sub-projectile 12 can be constructed of any suitable material, such as a dense metal or dense metal alloy.

[0024]The launch package 11 is adapted to be launched from a gun barrel along a predetermined launch axis. This launch axis is parallel to or coincides with an axis 19 of the sub-projectile 12.

[0025]The diameter of the sub-projectile 12 is less than the inside diameter of the gun bore used to launch the launch package 11. Consequently, the launch package 11 includes a sabot 10 which is comprised of a number of petals 20 that encase at least a portion of the sub-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com