Method and apparatus for controlling a constant current output in a switching mode power supply

a power supply and constant current technology, applied in the direction of dc-dc conversion, power conversion systems, instruments, etc., can solve the problems of greater noise, electromagnetic interference at the switching frequency or harmonic of the power transistor, and the output performance limitation of the switched mode power supply, so as to reduce or eliminate the error in the conduction time interval signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

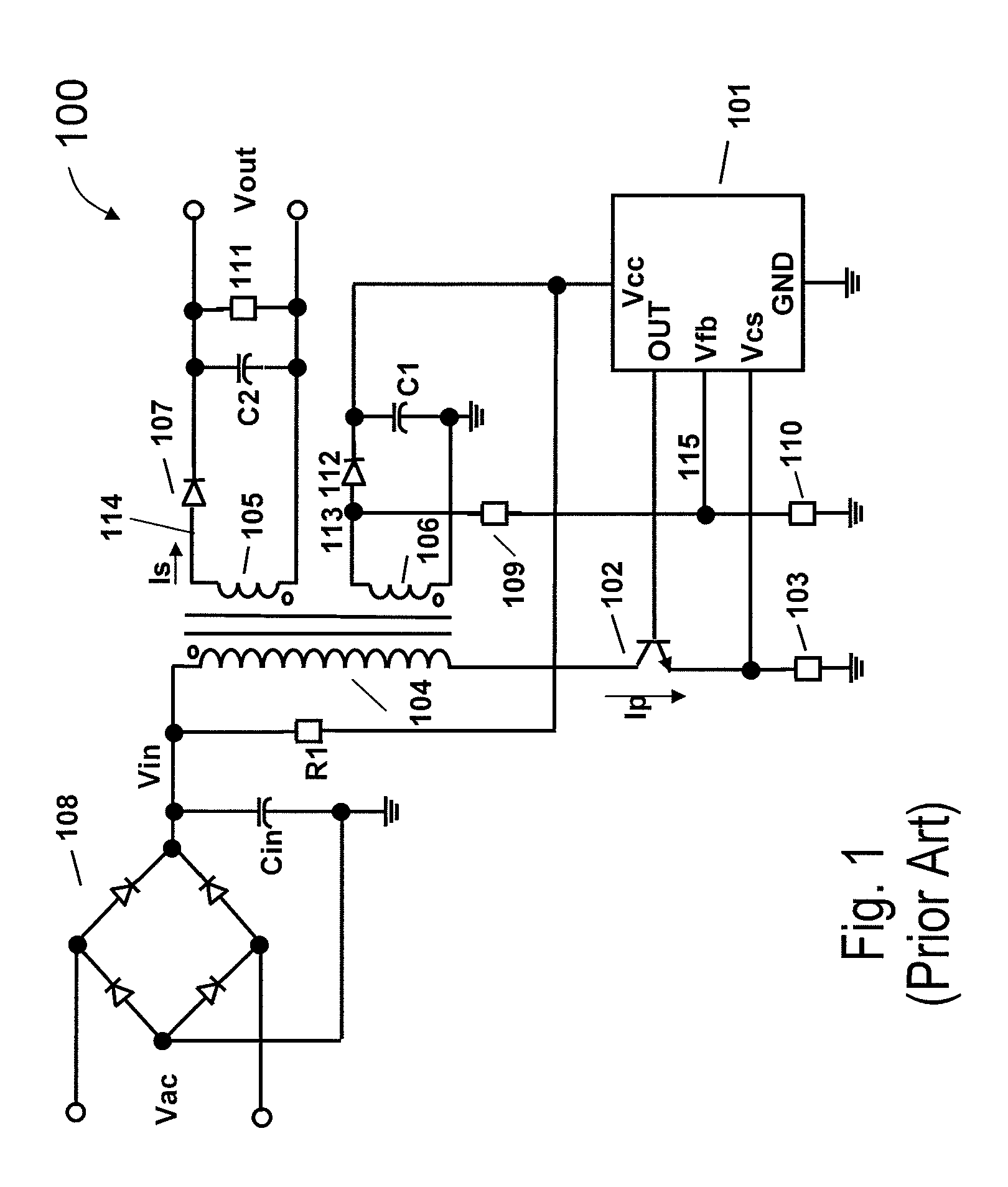

[0040]FIG. 1 is a circuit diagram of a conventional flyback-type primary side regulated switched mode power supply using a pulse width modulation (PFM) control. The primary side regulated switched mode power supply includes a rectifier 108 that converts an AC mains voltage to an unregulated voltage Vin. A capacitor Cin smoothes voltage Vin, which is then applied to a terminal of a primary winding 104. The another terminal of primary winding 104 is coupled to a transistor 102, which is turned on and off by a signal OUT of a PFM controller 101. When transistor 102 is turned on, a primary current Ip flows through primary winding 104, which starts building up a magnetic energy. A secondary winding 105 is magnetically coupled to primary winding 104 and includes a diode 107 and a capacitor C2, which has a relatively high capacity to stabilize the variation of a voltage Vout applying to a load 111. The polarity (winding sense) of secondary winding 105 is such that the magnetic field produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com