Method of forming a layer on a semiconductor substrate

a technology of semiconductor substrate and layer, which is applied in the direction of coating, chemical vapor deposition coating, metallic material coating process, etc., can solve the problems of affecting the performance difficult to adhere to other materials, and difficult to dry-etch copper, so as to improve the manufacturing throughput improve the characteristics of the thin layer of the semiconductor device, and prevent the underlying layer from deteriorating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

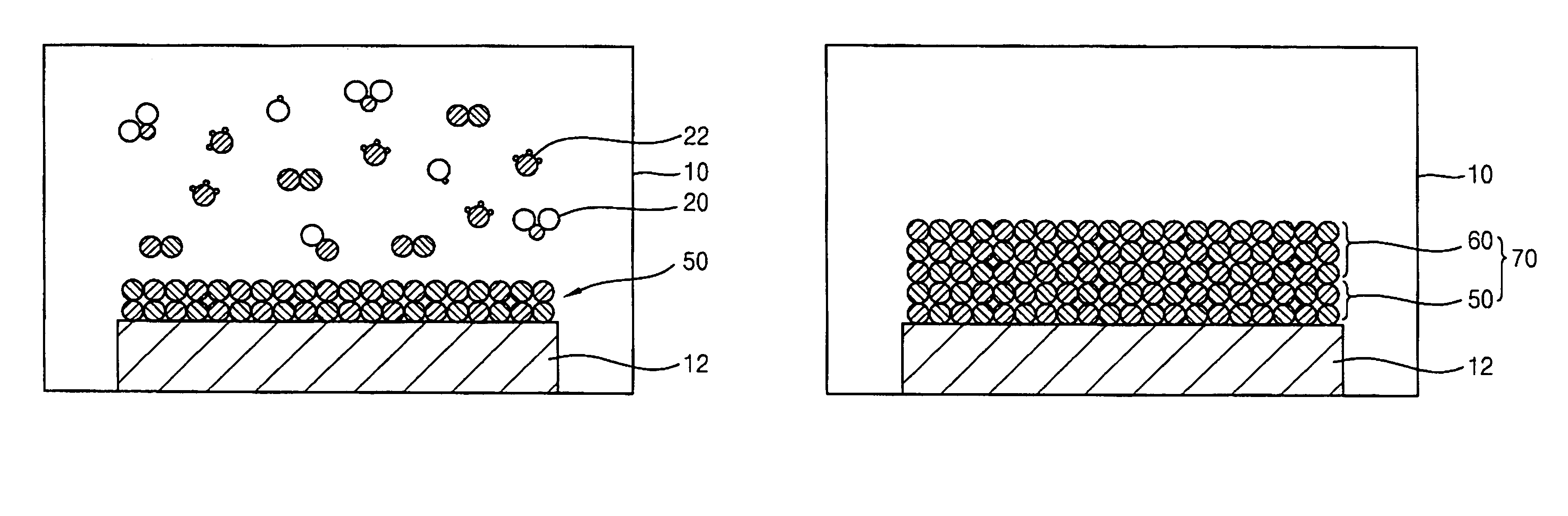

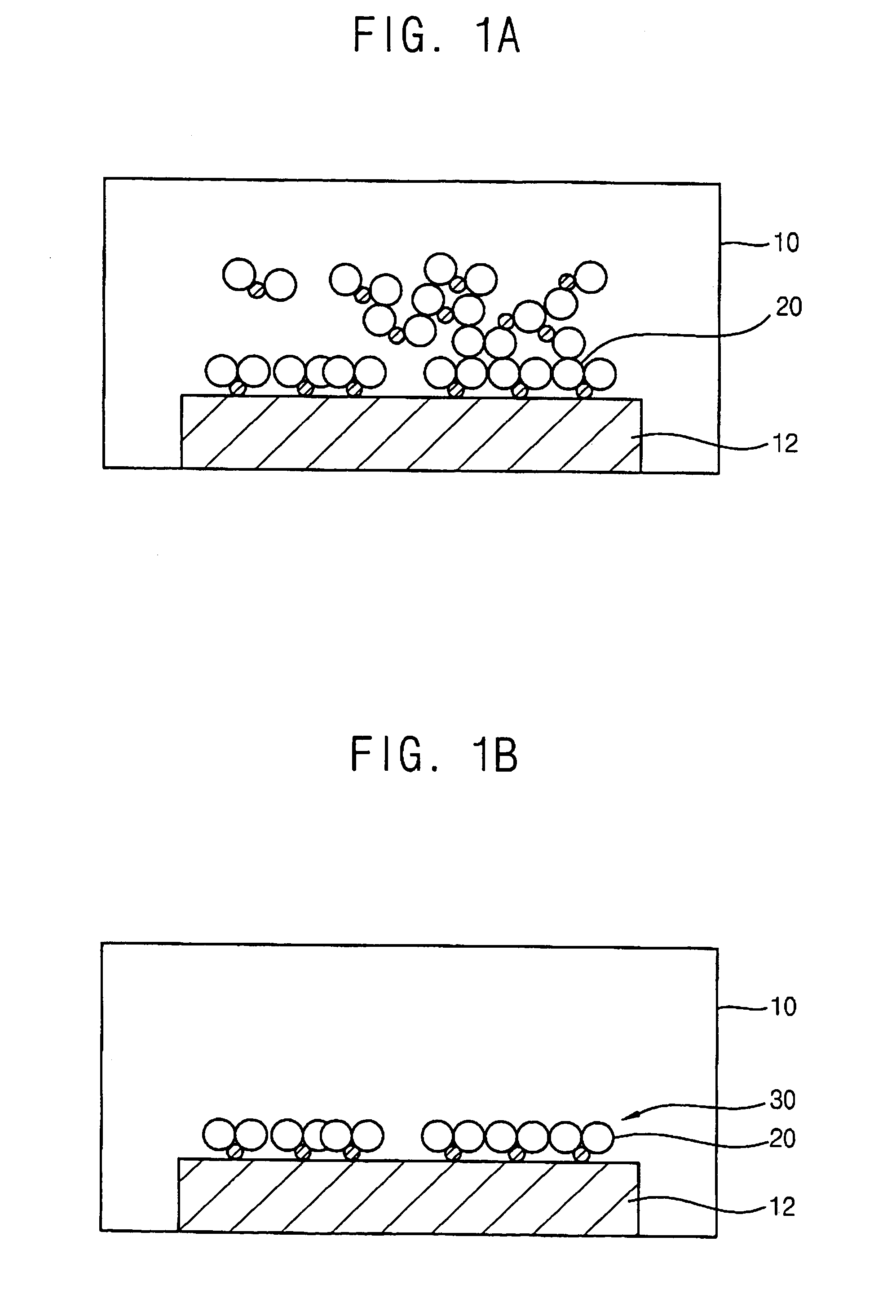

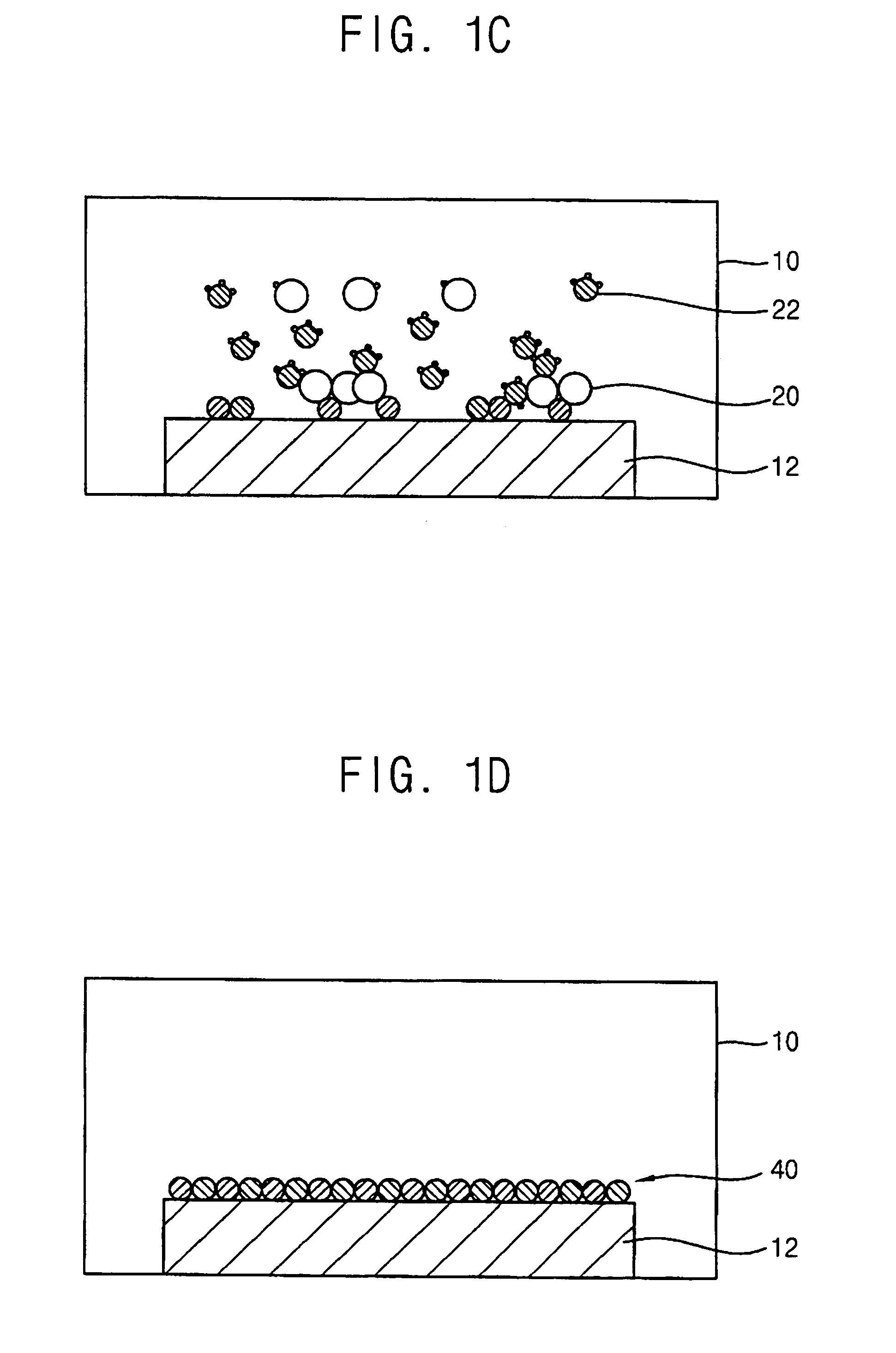

[0040]FIG. 2 is a cross sectional view illustrating an apparatus for forming a thin layer for a semiconductor device according to the present invention. FIGS. 3A and 3B are schematic views illustrating first and second layers of the thin layer formed on a substrate in the apparatus shown in FIG. 2.

[0041]Referring to FIG. 2, an apparatus 100 for forming a thin layer for a semiconductor device according to a first embodiment of the present invention includes a processing chamber 110 in which a semiconductor substrate 120 is positioned, a showerhead 140 through which reactants are provided into the processing chamber 110, an adjusting unit 160 for adjusting a gap distance between the showerhead 140 and the substrate 120, and a stage 130 for supporting the substrate 120. The showerhead 140 is positioned in an upper portion of the processing chamber 110, and the stage 130 is positioned in a lower portion of the processing chamber 110 and faces the showerhead 140.

[0042]In the present embo...

second embodiment

[0053]FIG. 4 is a cross sectional view illustrating an apparatus for forming a thin layer for a semiconductor device according to the present invention. FIGS. 5A and 5B are schematic views illustrating first and second layers of the thin layer formed on a substrate in the apparatus shown in FIG. 4.

[0054]Referring to FIG. 4, an apparatus 200 for forming a thin layer for a semiconductor device according to a second embodiment of the present invention includes a processing chamber 210 in which a semiconductor substrate 220 is positioned, a showerhead 240 through which reactants are provided into the processing chamber 210, an adjusting unit 260 for adjusting a gap distance between the showerhead 240 and the substrate 220, and a stage 230 for supporting the substrate 220. The showerhead 240 is positioned in an upper portion of the processing chamber 210, and the stage 230 is positioned in a lower portion of the processing chamber 210 and faces the showerhead 240.

[0055]In the present emb...

third embodiment

[0066]FIG. 6 is a cross sectional view illustrating an apparatus for forming a thin layer for a semiconductor device according to the present invention. FIGS. 7A and 7B are schematic views illustrating first and second layers of the thin layer formed on a substrate in the apparatus shown in FIG. 6.

[0067]Referring to FIG. 6, an apparatus 300 for forming a thin layer for a semiconductor device according to a third embodiment of the present invention includes a processing chamber 310 in which a semiconductor substrate 320 is positioned, a showerhead 340 through which reactants are provided into the processing chamber 310, first and second adjusting units 360 and 370 for adjusting a gap distance between the showerhead 340 and the substrate 320, and a stage 330 for supporting the substrate 320. The showerhead 340 is positioned in an upper portion of the processing chamber 310, and the stage 330 is positioned in a lower portion of the processing chamber 310 and faces the showerhead 340.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| gap distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com