Low refractive index coating composition for use in antireflection polymer film coatings and manufacturing method

a polymer film, low refractive index technology, applied in the direction of synthetic resin layered products, instruments, transportation and packaging, etc., can solve the problems of reducing the surface energy of the coating layer, reducing the interfacial adhesion of the fluoropolymer layer to the other polymer or substrate layer, and reducing the viscosity of the polymer material, etc., to achieve good wetting, adequate viscosity performance, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Fluoro-plastic / Silicone Alkoxy Oligomer System (“L-1”)

(a) Modification of Fluoroplastic

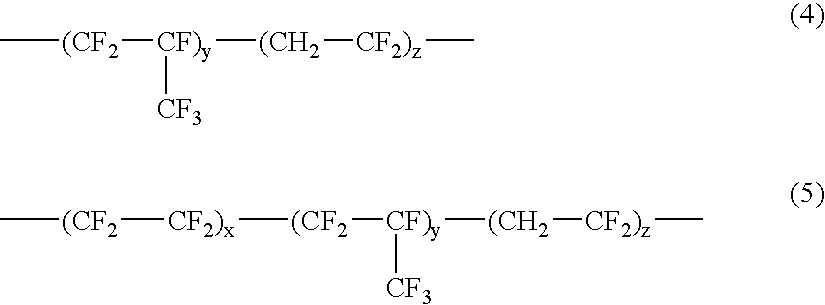

[0050]4 g of THV 220 (Dyneon) were dissolved in MEK and 40 g of a 10 weight percent solution was prepared. In the solution, 255 g of ethyl acetate and 0.74 g of a 60% by weight solution of oligomerized amino silane coupling agent (LJ-292130, Sumitomo 3M) were added and mixed. The solution was allowed to sit in an airtight container for 10 days under ambient conditions. After 10 days, the solution, known as a modified polymer solution, was slightly yellow. The solids percentage was about 1.5 weight percent and the weight ratio of THV 220 to oligomerized amino silane coupling agent was 90 / 10.

(b) Condensation with Silicone Alkoxy Oligomer

[0051]10 g of the modified polymer solution, 0.65 g of an organic alkoxy silane oligomer (SI oligomer 2, GE Toshiba silicone), 0.33 g of an oligo tetra methoxy silane (X40-2308, Shinetsu chemical), 4.9 g of methyl amyl ketone and 9.11 g of Ethyl acetat...

example 2

Preparation of Fluoro-Plastic / Silicone Alkoxy Oligomer System (“L-2”)

(a) Modification of Fluoroplastic

[0053]4 g of THV 220 (Dyneon) were dissolved in MEK and 40 grams of a 10 weight percent solution was prepared. In the solution, 240.5 g of THF and 0.21 g of an amino silane coupling agent (KBM-903, Shinetsu chemical) were added and mixed. The solution was then allowed to sit in an airtight container for 10 days under ambient conditions. After 10 days, the solution was slightly yellow. The measured solids percentage of the mixture was about 1.5 weight percent and the weight ratio of THV 220 / KBM-903 was measured at 95 / 5.

(b) Condensation with Silicone Alkoxy Oligomer

[0054]10 g of the modified polymer solution, 0.9 g of an organic alkoxy silane oligomer (SI oligomer 2, GE Toshiba silicone), 0.63 g of an oligo tetra methoxy silane (X40-2308, Shinetsu chemical), and 7.23 g of THF were mixed in a container. The mixture was then coated onto a PET substrate material using a Mayer bar, and th...

example 3

Preparation of Fluoro-elastomer / Silicone alkoxy oligomer system (“L-3”)

(a) Modification of Fluoroelastomer

[0057]40 g of FT-2430 (Dyneon) were dissolved in MEK and 400 grams of a 10 weight percent solution was prepared. In the solution, 1001.4 g of THF and 2.11 g of an amino silane coupling agent (KBM-903, Shinetsu chemical) were added and mixed. This solution was allowed to sit in an airtight container for 10 days under ambient conditions. After 10 days, the solution was slightly yellow. The solids percentage was measured at about 3.0 weight percent and the weight ratio of FT-2430 / KBM-903 was determined to be 95 / 5.

(b) Condensation with Silicone Alkoxy Oligomer

[0058]400 g of the modified polymer solution, 72 g of an organic alkoxy silane oligomer (SI oligomer 2, GE Toshiba silicone), 50 g of an oligo tetra methoxy silane (X40-2308, Shinetsu chemical), 24 g of THF and 54 g of PMA were mixed in a container. The mixture was then coated onto a PET substrate material using a Mayer bar, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| refractive indices | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com