Guided punching apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075]Embodiments of the invention will be described below with reference to the accompanying drawings. Firstly, the constitution of a liquid ejection head will be described.

[0076]Since it is preferable to apply the invention to a recording head of an ink jet recording apparatus, as an example representative of the liquid ejection head, the above recording head is shown in the embodiment.

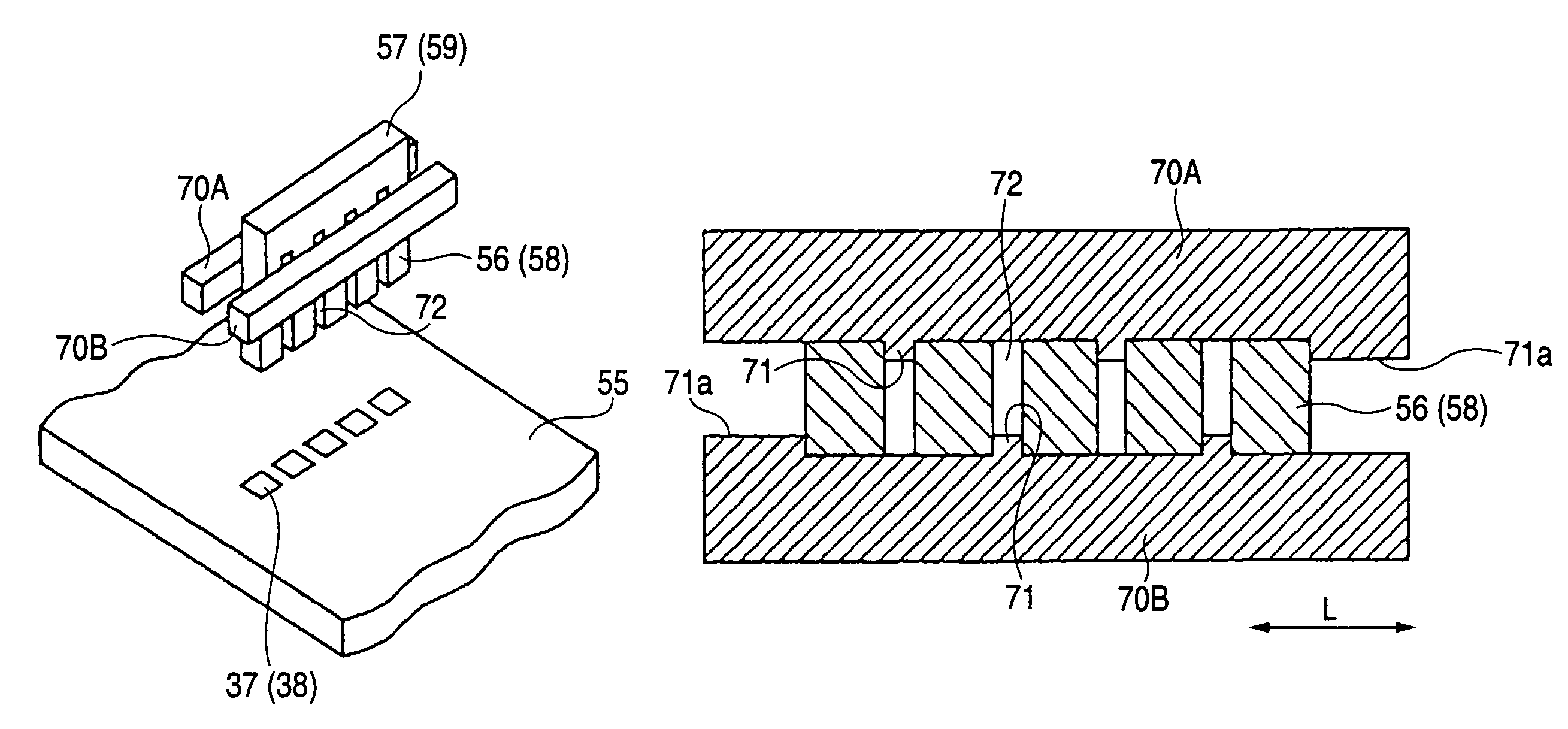

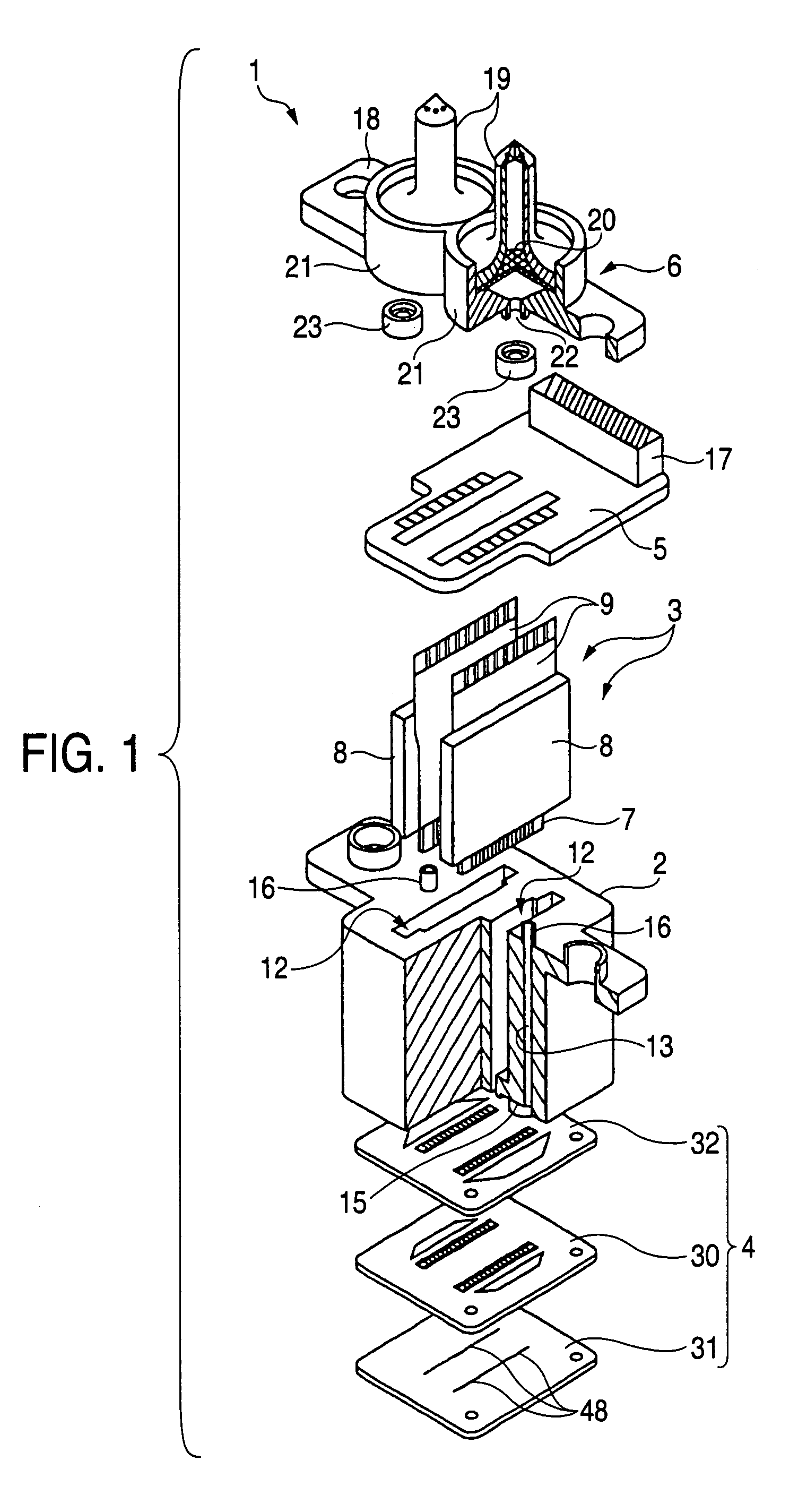

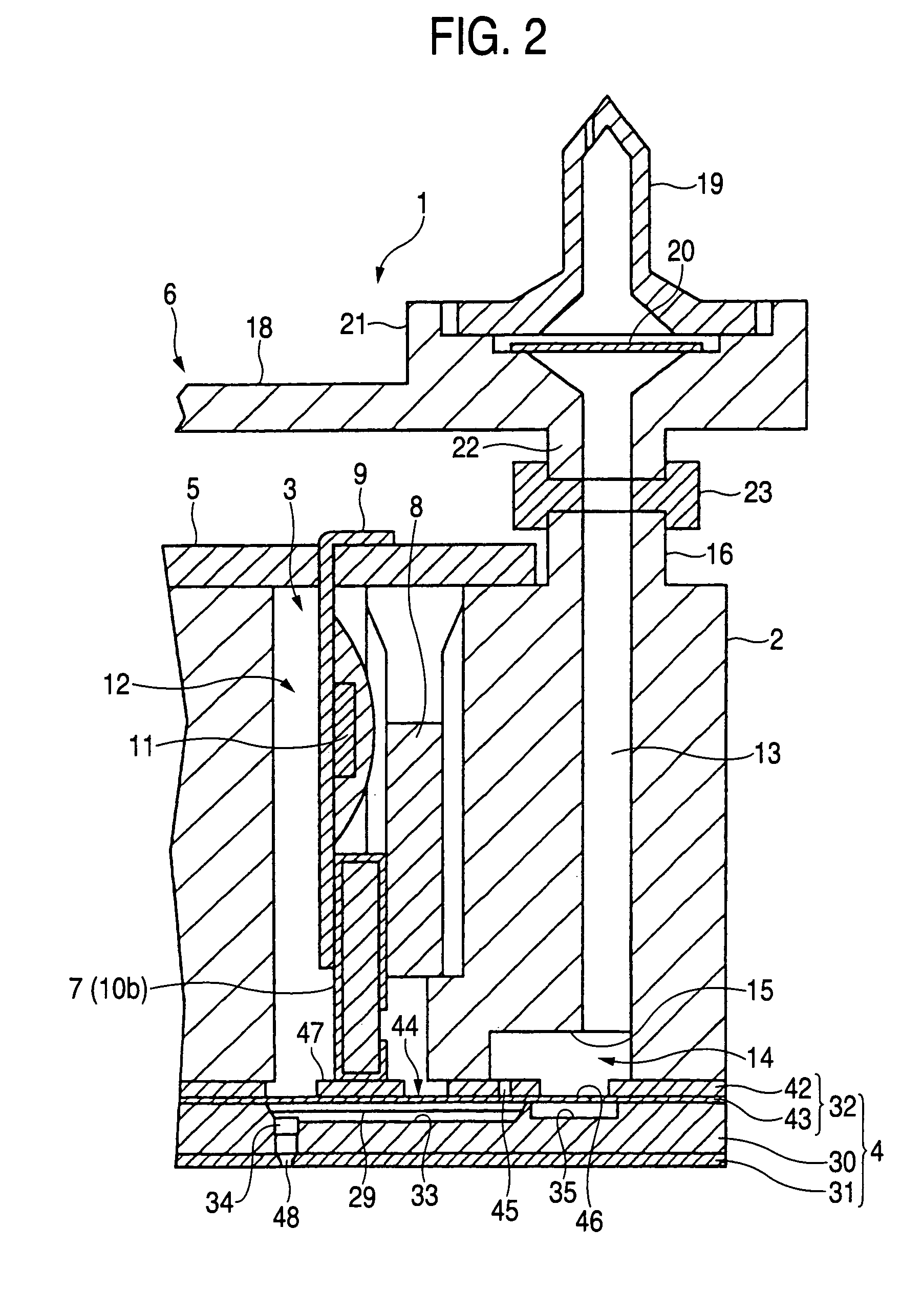

[0077]As shown in FIGS. 1 and 2, a recording head 1 is roughly constituted by a casing 2, a vibrator unit 3 contained at inside of the casing 2, a flow path unit 4 bonded to a front end face of the casing 2, a connection board 5 arranged onto a rear end face of the casing 2, a supply needle unit 6 attached to the rear end face of the casing 2.

[0078]As shown in FIGS. 3A and 3B, the vibrator unit 3 is roughly constituted by a piezoelectric vibrator group 7, a fixation plate 8 bonded with the piezoelectric vibrator group 7 and a flexible cable 9 for supplying a drive signal to the piezoelectric vibrato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com