Polarizing electrode, manufacturing method thereof, and electric double-layer capacitor

a technology of double-layer capacitors and polarizing electrodes, applied in the direction of electrolytic capacitors, cell components, hybrid cases/housings/encapsulations, etc., can solve the problems of double-layer capacitors not being able to offer a sufficient performance, unable to carry out a function, and unable to meet the requirements of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiments

(Embodiments)

[0031]Hereinafter, the embodiments of a polarizing electrode according to the present invention, a manufacturing method thereof, and an electric double-layer capacitor using it will be described.

example 1

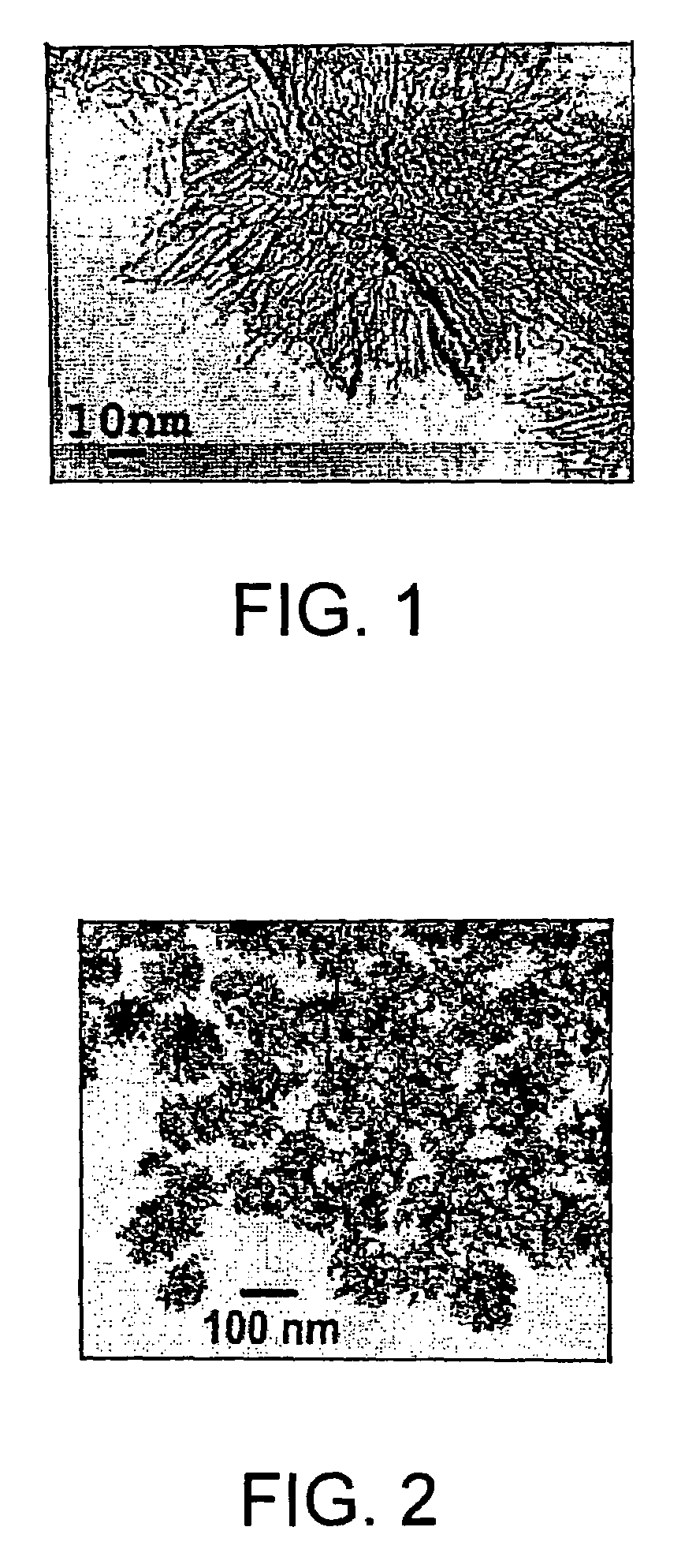

[0032]At first, a single-layer carbon nanohorn aggregate was manufactured by a laser ablation method targeting graphite in an inactive gas atmosphere of 760 Torr at a room temperature, and then, the manufactured carbon nanohorn aggregate was treated with a nitricacid solution. Consequently, mixing the single-layer carbon nanohorn aggregate treated with the nitricacid solution with a heat fusible and heat hardening phenol resin powder (a bellpearl S-type, made by Kanebo Corporation) at a weight ratio of 7:3, further, a dry blending was carried out by a ball mill. In the meantime, the single-layer carbon nanohorn aggregate used here is a single-layer carbon nanohorn aggregate composed of single-layer carbon nanohorns. Then, a specific surface area of this single-layer carbon nanohorn aggregate was 1,300 m2 / g.

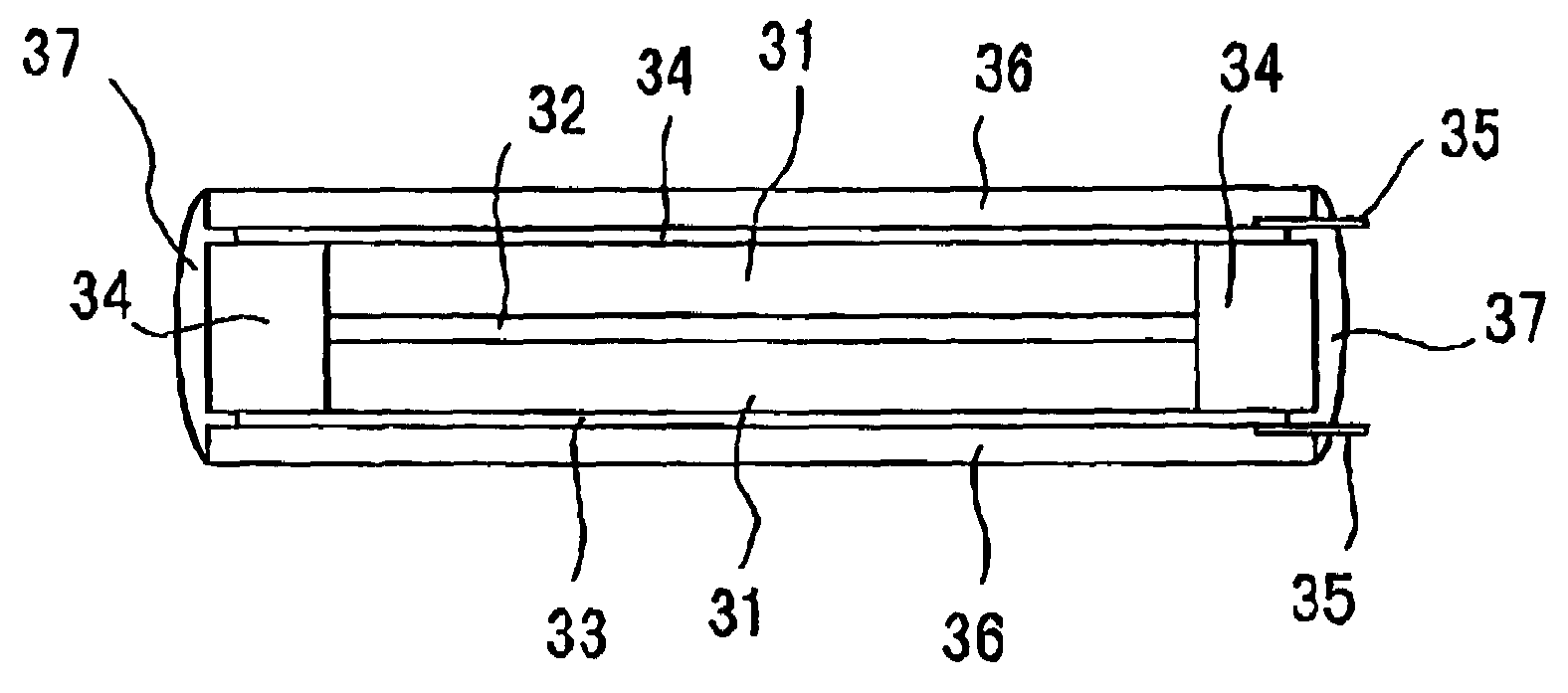

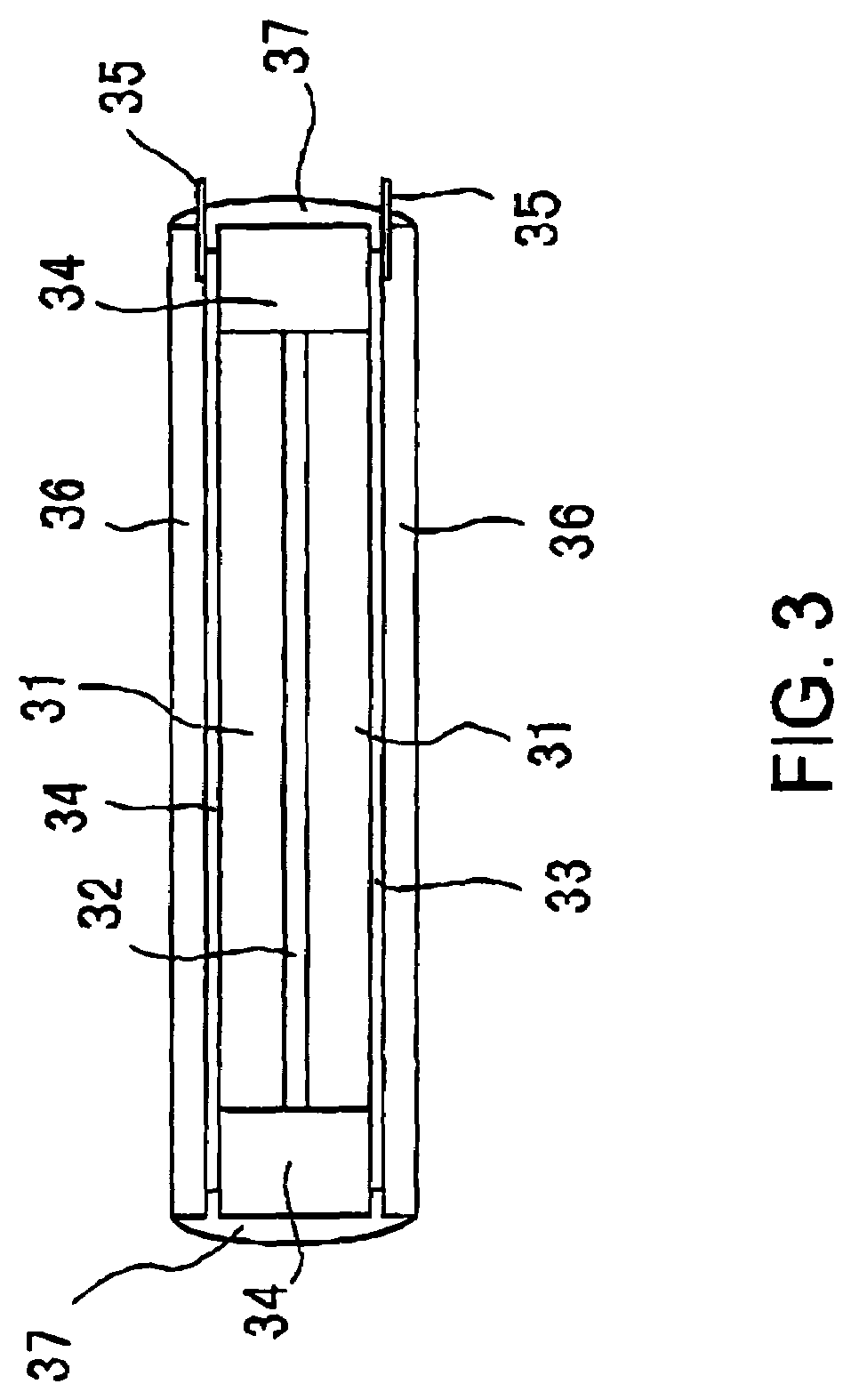

[0033]Dividing the mixture powders made as described above into 10 g each, and molding them at 150° C., at a pressure of 100 kg / cm2, for ten minutes, a plurality of single-layer c...

example 2

[0041]At first, in the same way as the example 1, the single-layer carbon nanohorn aggregate was made according to the laser ablation method, and it was treated with the nitricacid solution. Then, by placing the single-layer carbon nanohorn aggregate treated with the nitricacid solution in a vacuum of 1×10−3 Torr together with a carbon nanofiber, and providing a heat treatment to them, a front end of the single-layer carbon nanohorn aggregate was fused (supported) by the carbon nanofiber. The specific surface area of the material allowing this single-layer carbon nanohorn aggregate supported by the carbon nanofiber was 1,350 m2 / g.

[0042]As same as the example 1, after mixing the above-described material with the phenol resin powder at a weight ratio of 7:3, further, the dry blending was carried out by the ball mill. Then, dividing the mixture powders into 10 g each, and molding them at 150° C., at a pressure of 100 kg / cm2, for ten minutes, the single-layer carbon nanohorn aggregates / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com