Microplate liquid handling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

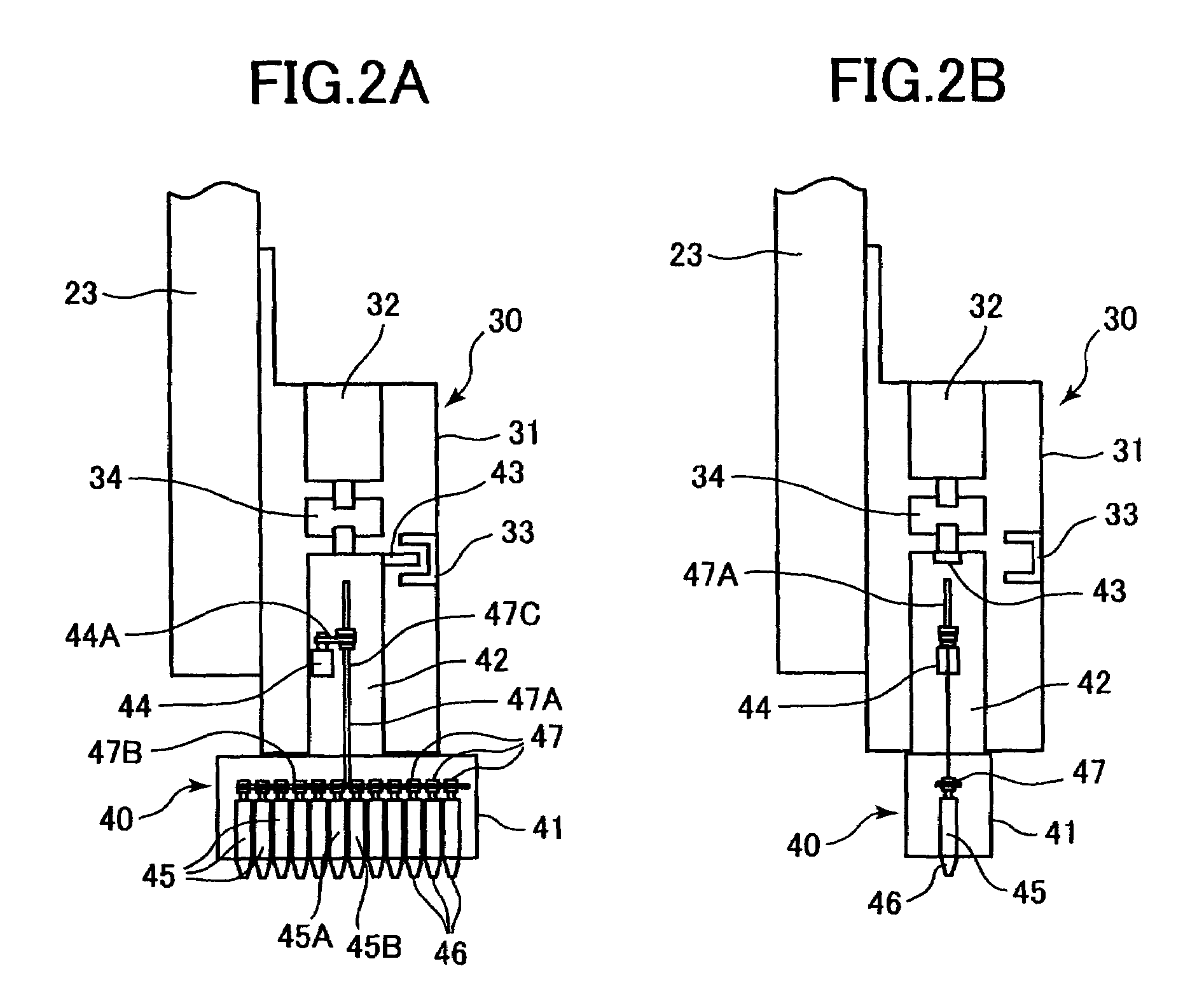

[0023]A microplate liquid handling system according to the present invention will now be described with reference to FIGS. 1 through 5. A microplate liquid handling system 1 has a main body 10, which is equipped with a moving mechanism 20, a rotating mechanism 30, a dispensing mechanism 40, and a stage 50. The main body 10 has a substantially rectangular box-like outward configuration, and defines therein a substantially rectangular chamber 10a which is substantially geometrically similar to the outward configuration of the main body 10. Partially formed in an upper surface 10A and a front surface 10B of the main body 10 are openings 10b and 10c outwardly open from within the chamber 10a. The openings 10b and 10c have rectangular configurations which are respectively substantially geometrically similar to those of the upper surface 10A and the front surface 10B. The stage 50 is provided on an inner peripheral surface defining the chamber 10a, on a bottom surface 10C of the main body...

second embodiment

[0071]Further, in the second embodiment the abutment member 12 is provided on the inner peripheral surface defining the chamber 10a inside the main body 10 and extending in parallel to the X-axis member 21A. However, the abutment member can be provided on another inner peripheral surface extending in parallel to the Y-axis member 22.

[0072]Further, in order to provide constant pressure between the pulley 48 and the abutment member 12, as shown in FIG. 7, a support stand 13 can extend from the main body 10, and the abutment member 12 is supported on the support stand 13. Further, a spring 14 is interposed between the abutment member 12 and the inner peripheral surface of the main body 10, for urging the abutment member 12 toward the pulley 48.

[0073]Further, in order to prevent the pulley 48 from slipping with respect to the abutment member 15 during rotation of the dispensing mechanism 40, as shown in FIG. 7, a resilient member 15 formed of a rubber or the like can be laid on the enti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com