Extrusion nozzle

a technology of extrusion nozzle and extrusion nozzle, which is applied in the direction of bakery products, applications, manufacturing tools, etc., can solve the problems of void creation, difficult to have a complex outlet configuration, and relatively complex nozzle outlet configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

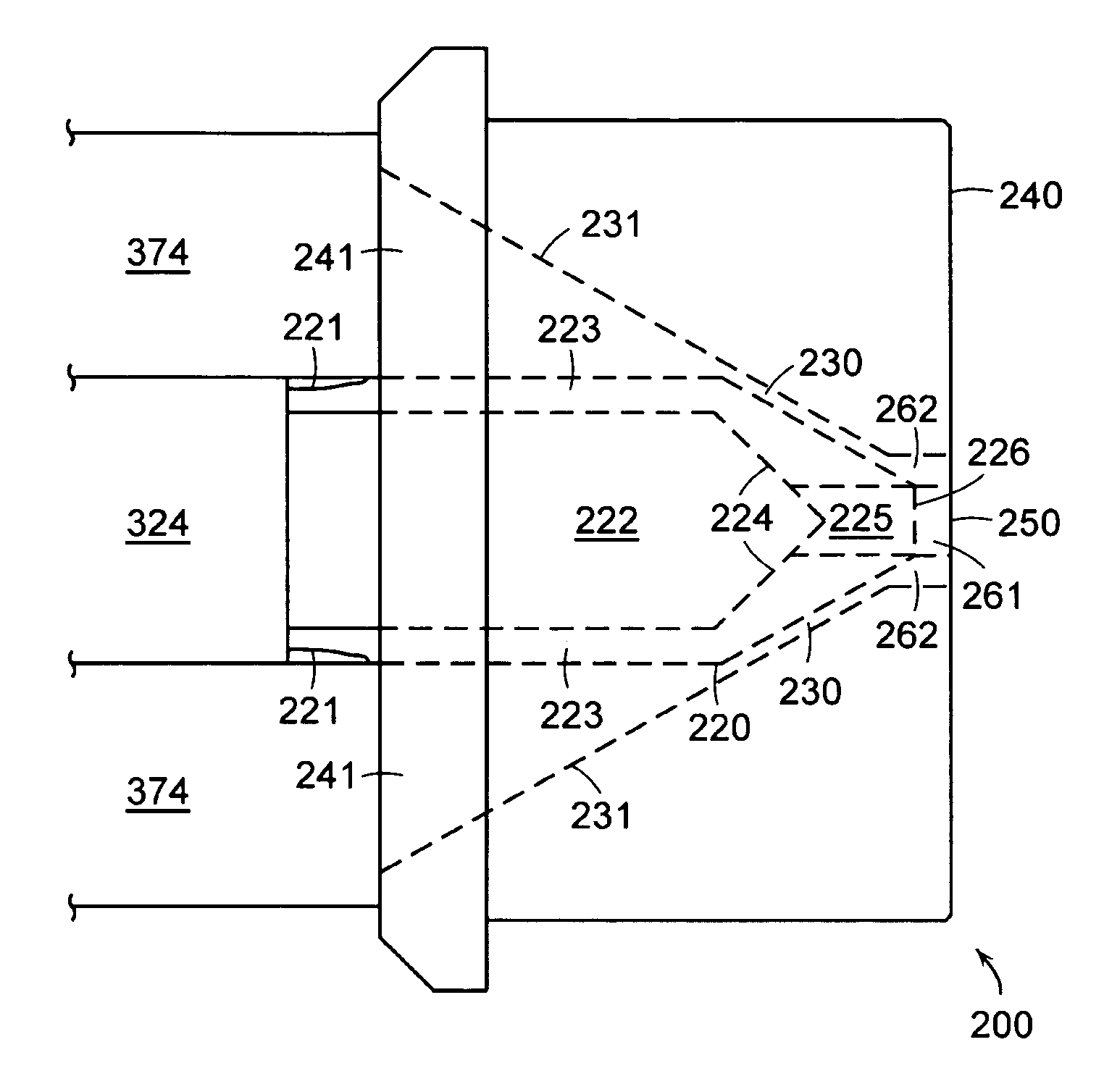

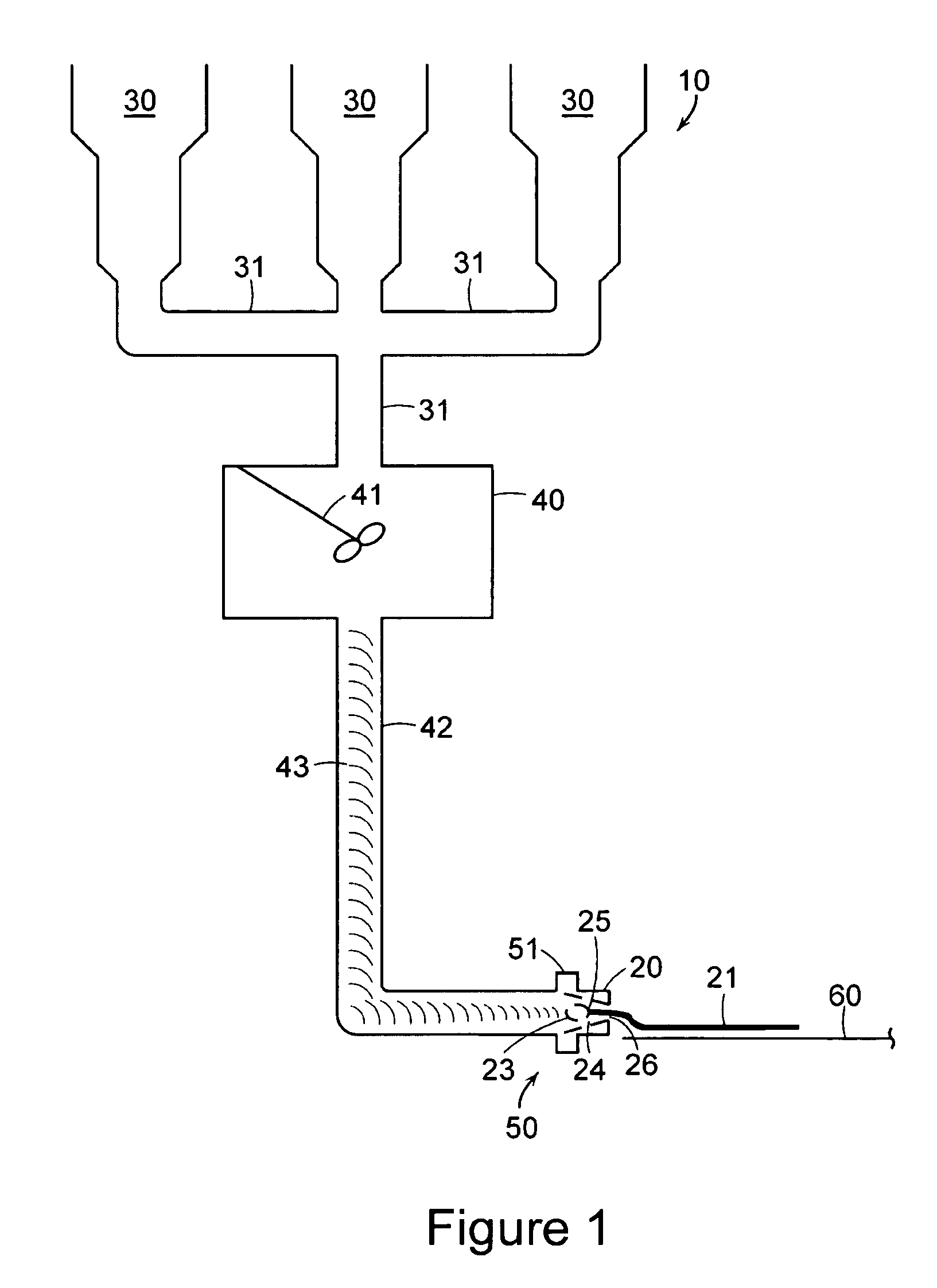

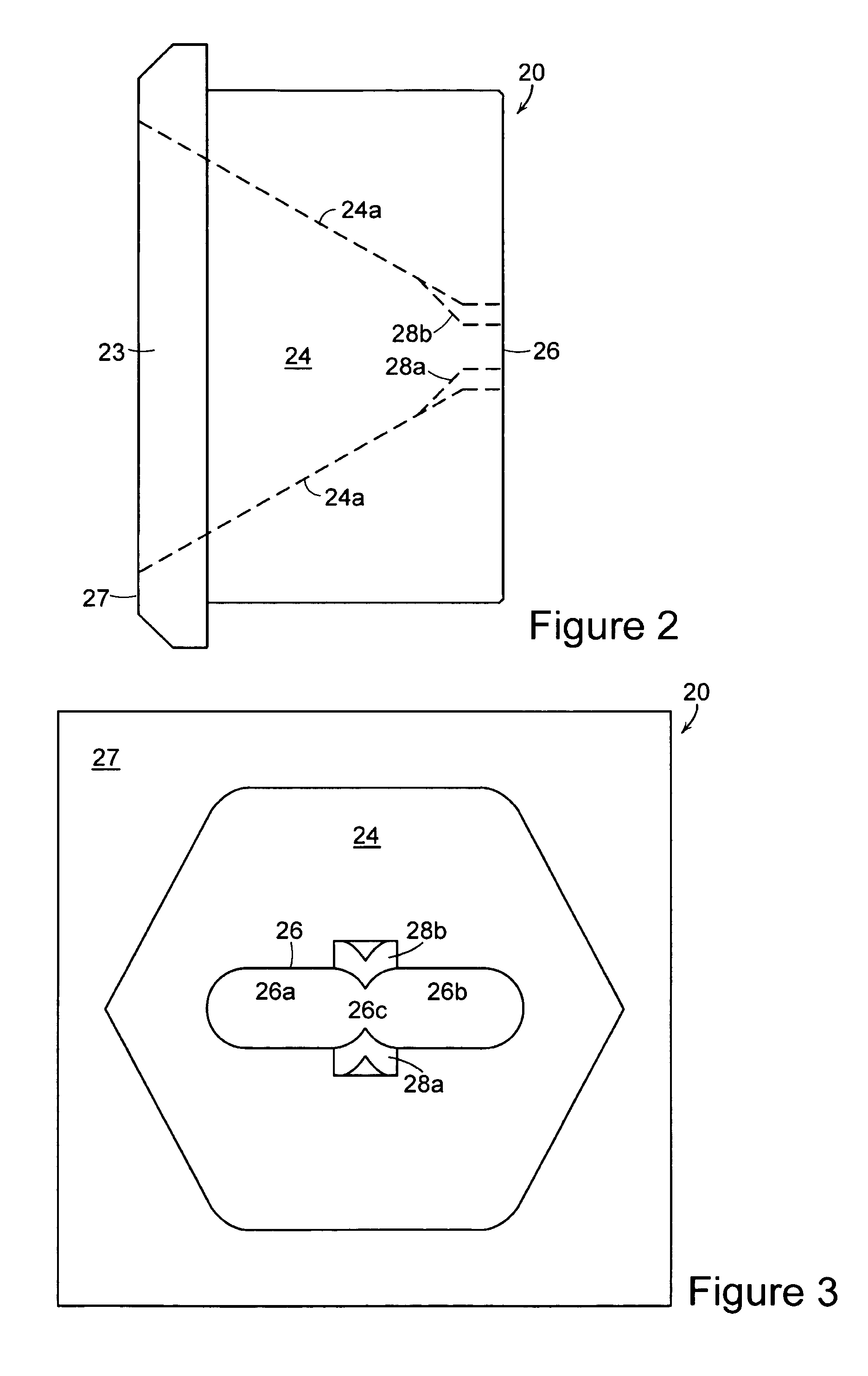

[0025]A material processing system 10 of the present invention is shown in FIG. 1. The system 10 includes an extrusion nozzle 20 designed to create an attached paired rope extrudate shown generically as extrudate 21. The extrusion nozzle 20 is the primary component of the present system 10; however, the system 10 also includes commonly used materials processing equipment including, but not limited to, one or more material component delivery hoppers 30, component delivery piping or ducts 31, a mixer unit 40 with mixer 41, and mixed material delivery piping 42. The delivery piping 42 acts to transfer mixed material 43 from the mixer 40 to an extrusion head 50 that includes the extrusion nozzle 20 and a coupling flange 51. The mixed material 43 may be directed through the delivery piping 42 to the extrusion head 50 by way of a pumping device associated with the mixer unit 40. It is to be understood that the mixed material 43 may be formed of one or more components and may be any form o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com