Puncture proof material with capture devices

a technology of puncture proof material and capture device, which is applied in the field of protective puncture proof material, can solve the problems of high risk of infection from needlesticks and other sharp instruments, harmful effects of needlesticks and scalpels on inability to accept risk factors for surgeons and other medical personnel, so as to achieve flexibility and elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

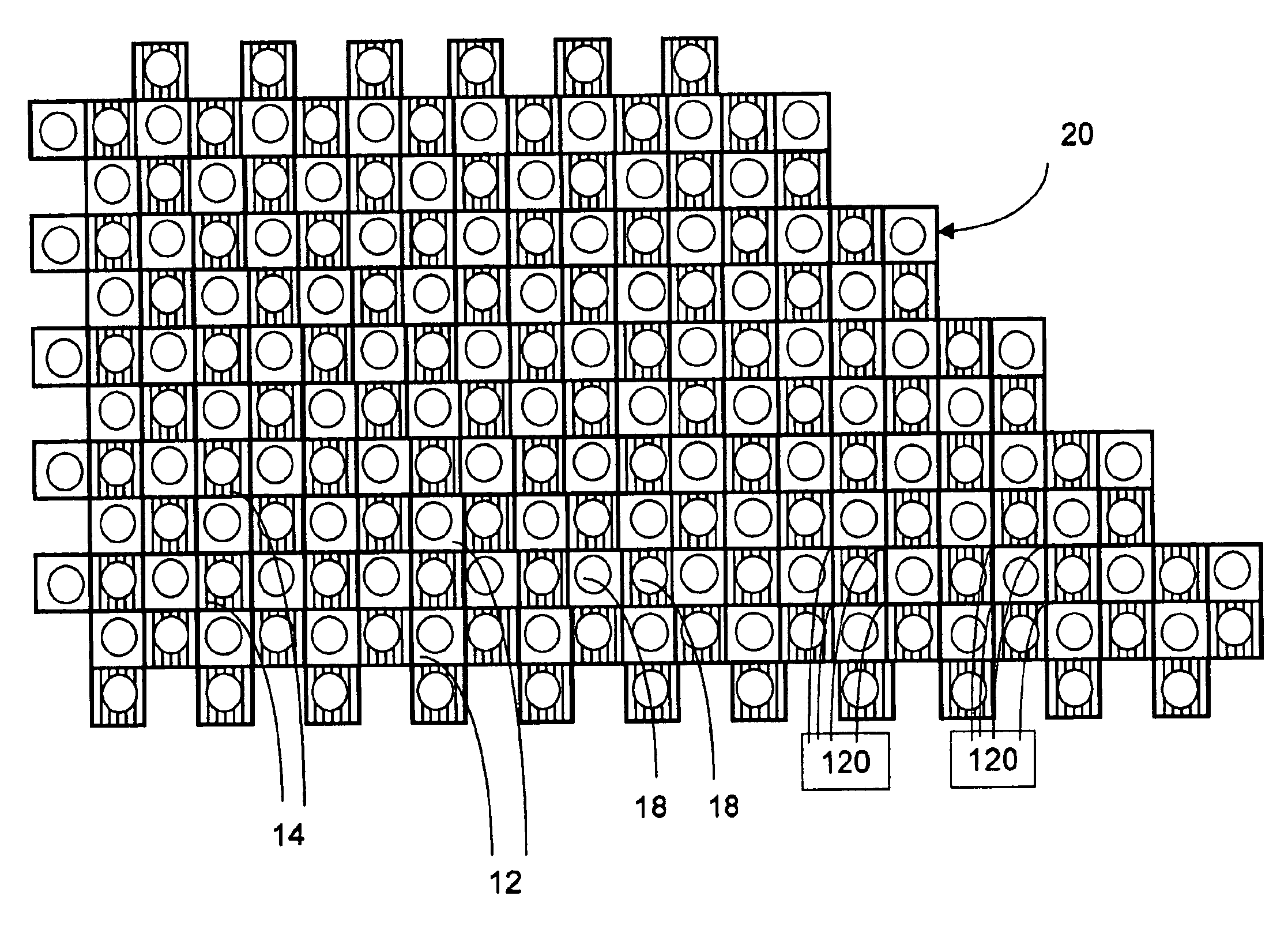

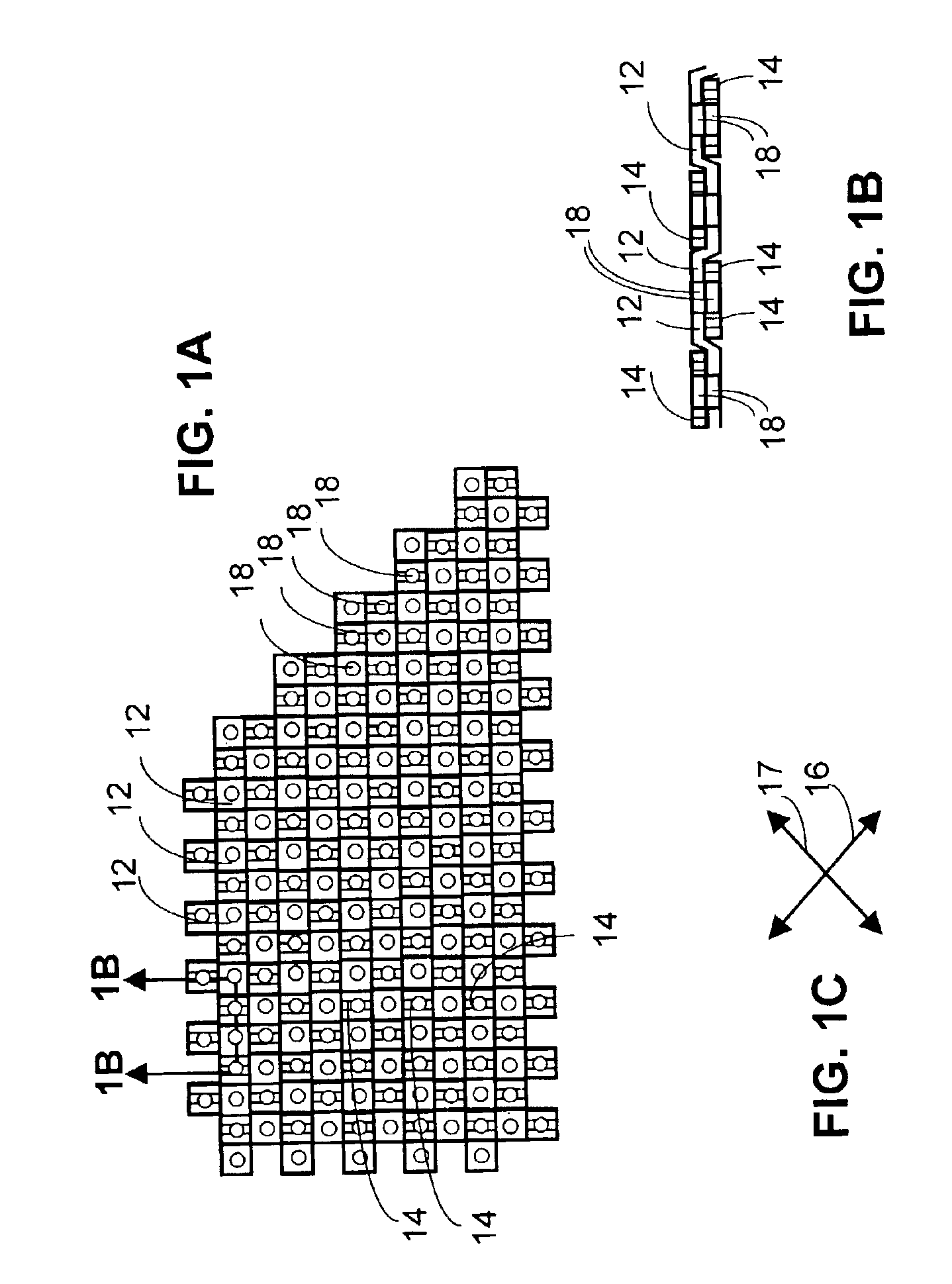

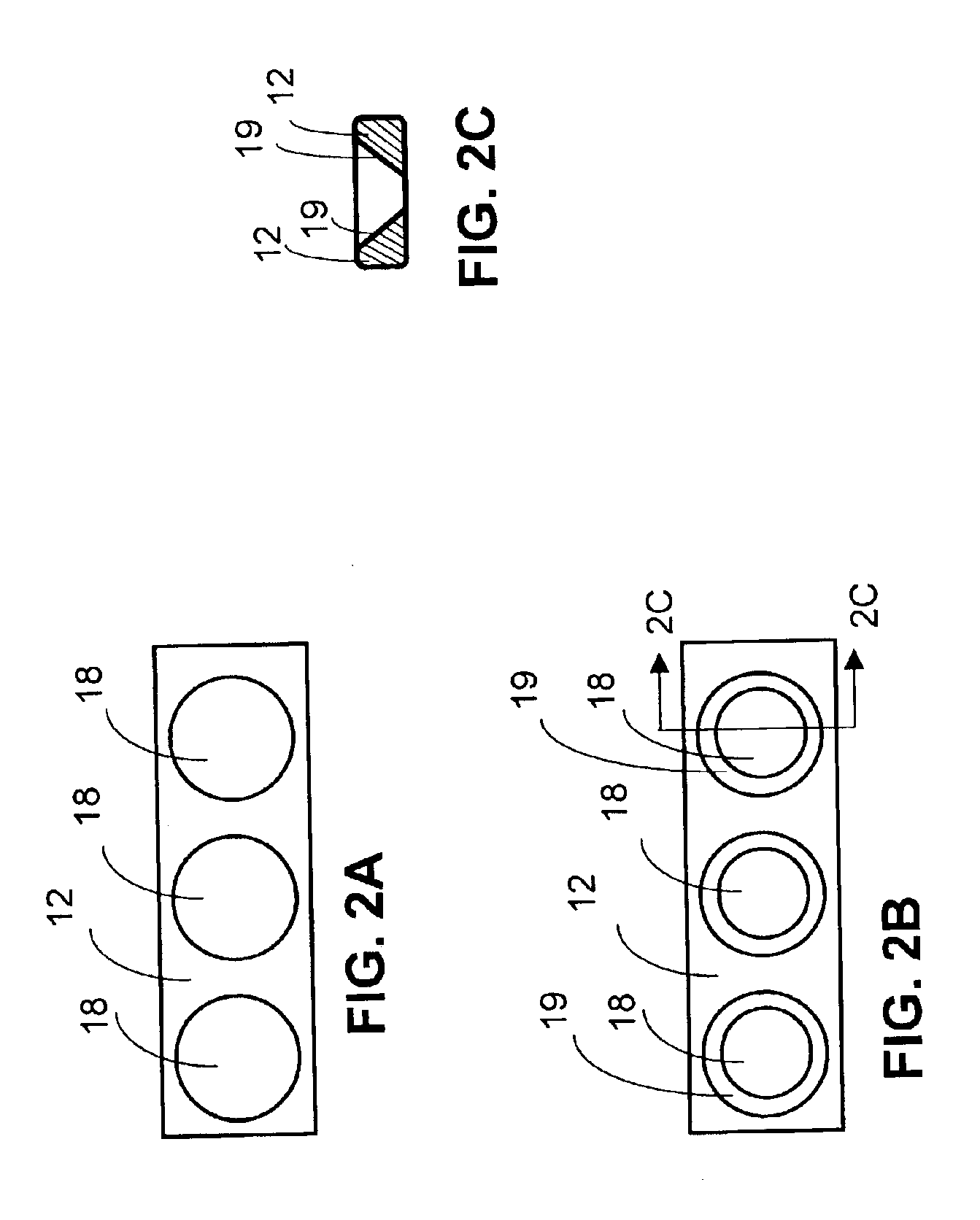

The requirements for a material suitable for a puncture resistant surgical underglove are extreme and demand flexibility, elasticity, conformity to a compound curve of very small radius (1 to 2 millimeters), maximal tactile transmission of touch, and puncture resistance in the range of 1,800 grams. The use of woven strips of material provides stability against rotation of the strips in their own axis. If the woven strips have a “capture element”, then a needle point encountering the material will not simply slide past successive layers of the material seeking an opening. In particular the specific requirements for such a material include the following. The woven material should provide a “capture element” to arrest the progress of a needle or other sharp instrument point in contact with the material. The strips of the woven material should be thin with as narrow as possible width to enhance flexibility, and elasticity at 45 degrees to an x-y axis of the woven material. The material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com