Device for compensating for a test temperature deviation in a semiconductor device handler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

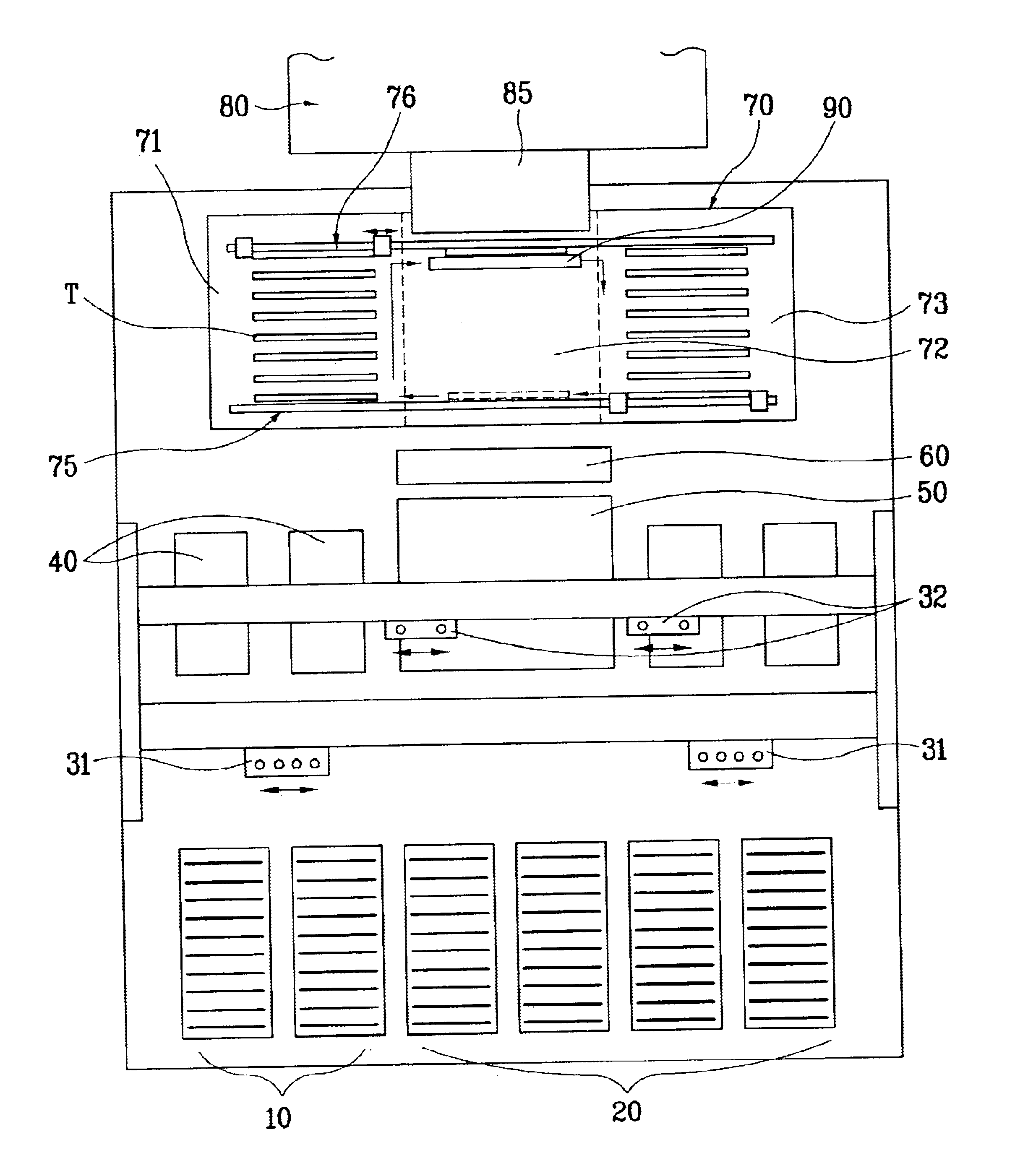

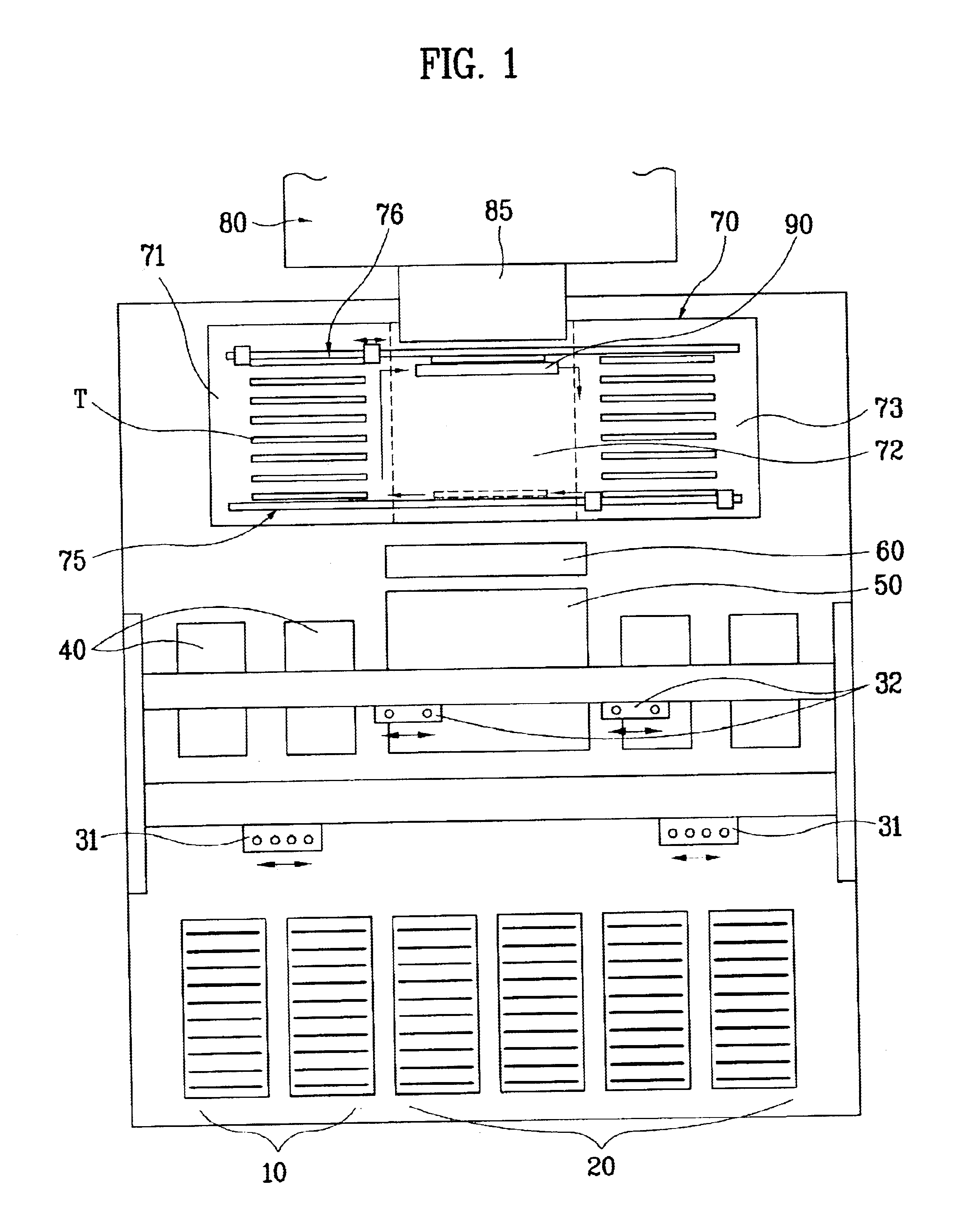

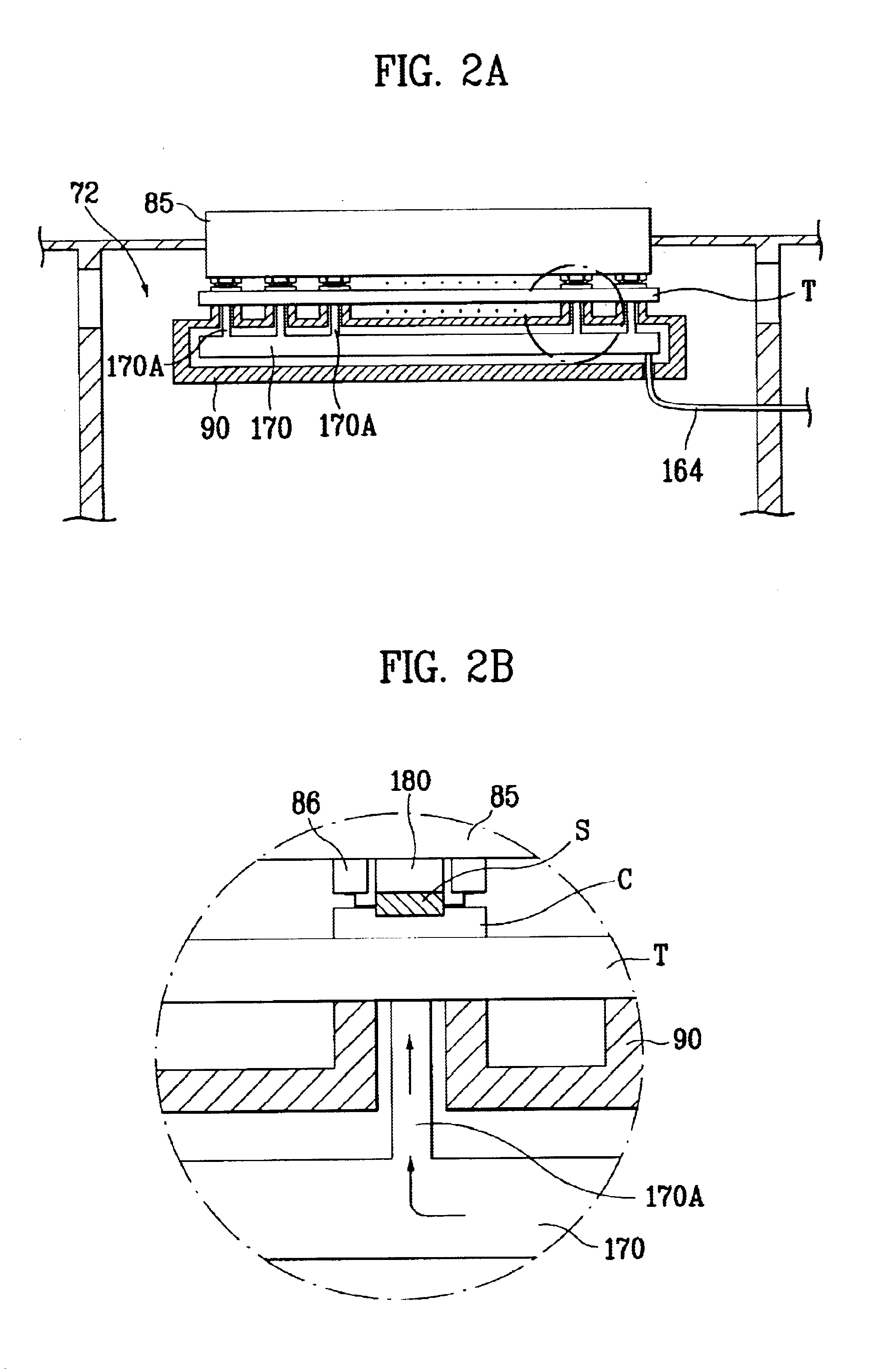

Reference will now be made in detail to the embodiments of the present invention, examples of which are illustrated in the accompanying drawings. FIG. 1 is a schematic plan view of a handler having a device for compensating a test temperature deviation in accordance with the invention. FIGS. 2A and 2B are schematic side sectional views of a test site of the handler of FIG. 1.

The handler and its operation will be explained as follows.

The handler shown in FIG. 1 includes a loading unit 10 in a front portion of the handler 1, in which user trays may be loaded, and an unloading unit 20 to one side of the loading unit 10, in which tested semiconductor devices may be loaded on the user trays, with the tested semiconductor devices classified according to a result of the test(s).

Buffer units 40 are provided on both sides of a middle position of the handler 1. The buffer units 40 temporarily retain the semiconductor devices transported from the loading unit 10. An exchange unit 50 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com