Enzyme processing of soybeans into intact oil bodies, protein bodies, and hydrolyzed carbohydrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

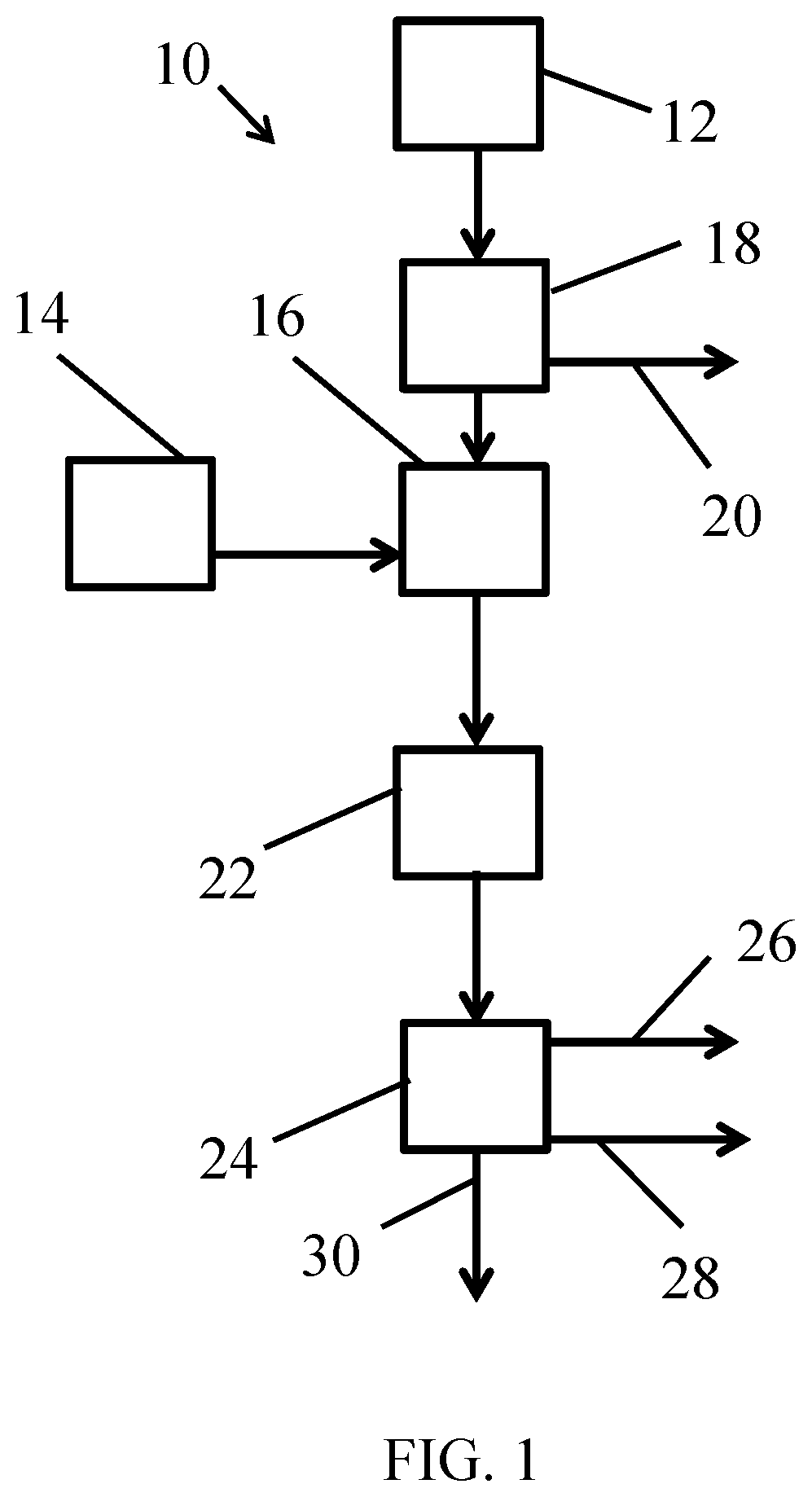

Method used

Image

Examples

examples

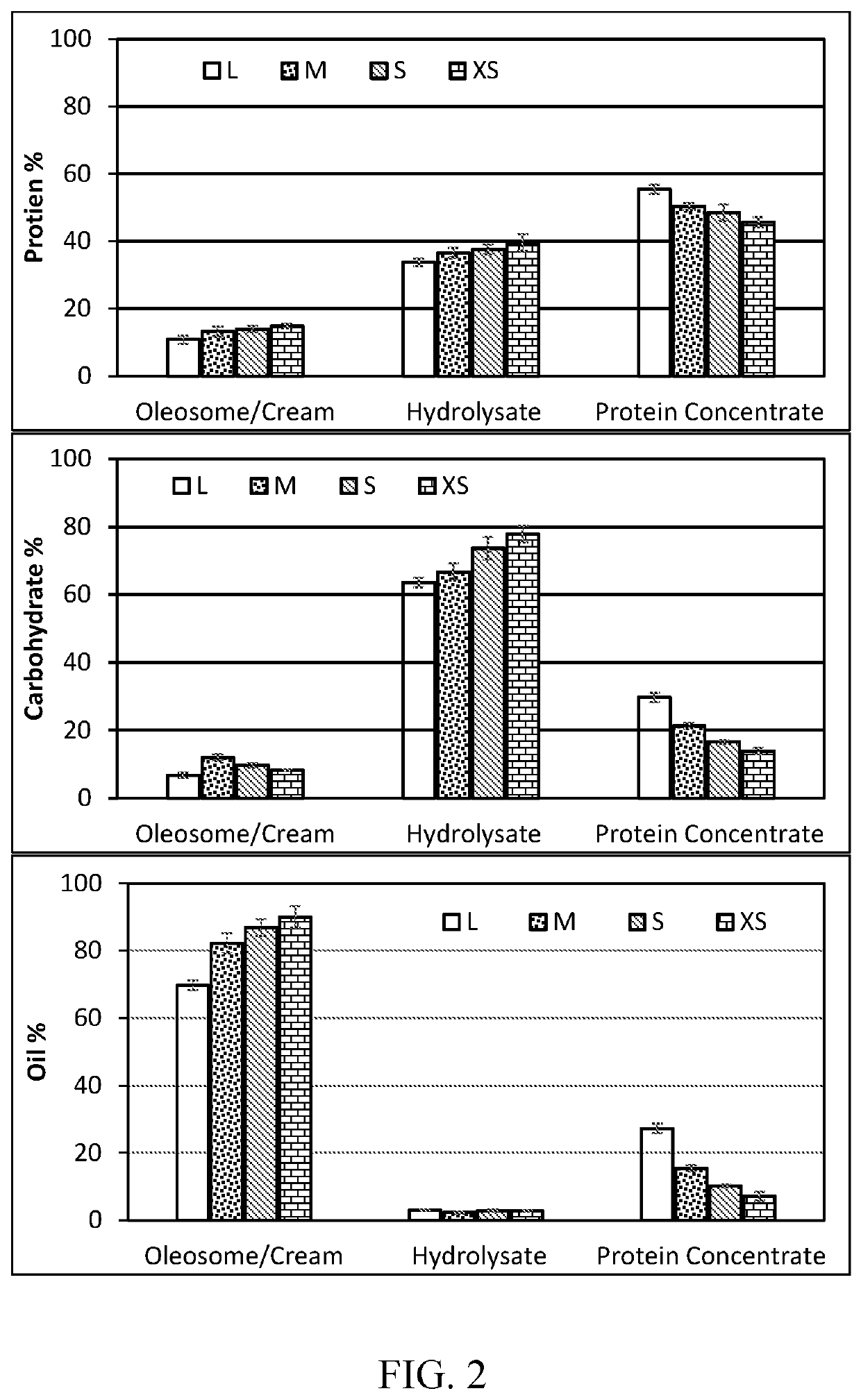

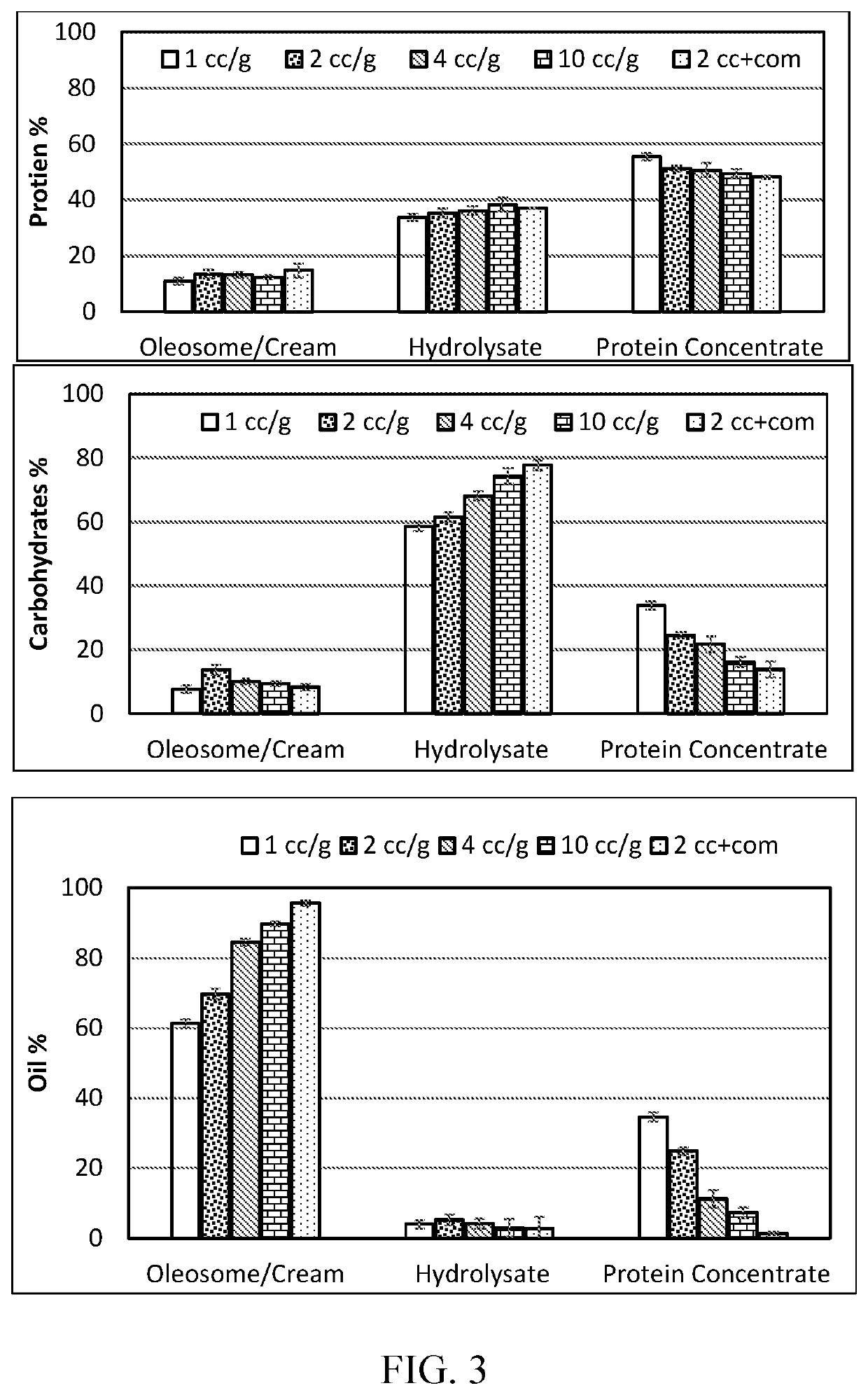

[0088]The following examples are offered to more fully illustrate the invention, but are not to be construed as limiting the scope thereof.

Materials & Equipment

[0089]Full-fatted, dehulled, cracked soybeans were provided by Archer Daniels Midland (Decatur, Ill.). (NH4)2SO4 (granular), KH2PO4 (99% purity), HCl (concentrated, 37.4%) and NaOH (98.8%) were purchased from Fisher Scientific (Waltham, Mass.). Proteose peptone (from meat, Type I, for microbiology), MgSO4.7H2O (99%), MnSO4.4H2O (99%), ZnSO4.7H2O (ACS reagent grade), CoCl2.6H2O, FeSO4.7H2O (reagent grade), CaCl2.2H2O (reagent grade), urea (98%), NaN3 (>99%) and dinitrosalicylic acid (DNS, 98%) were purchased from Sigma-Aldrich (St. Louis, Mo.). The Aspergillus niger (NRRL 341) seed culture was obtained from the United States Department of Agriculture (USDA) Agricultural Research Service (ARS) Culture Collection (Peoria, Ill.). Two 3-L Bioflo 110 fermentors (New Brunswick Scientific; Edison, N.J.) were used for enzyme productio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com