Method for producing an automotive friction material with optimized multi dimensional construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

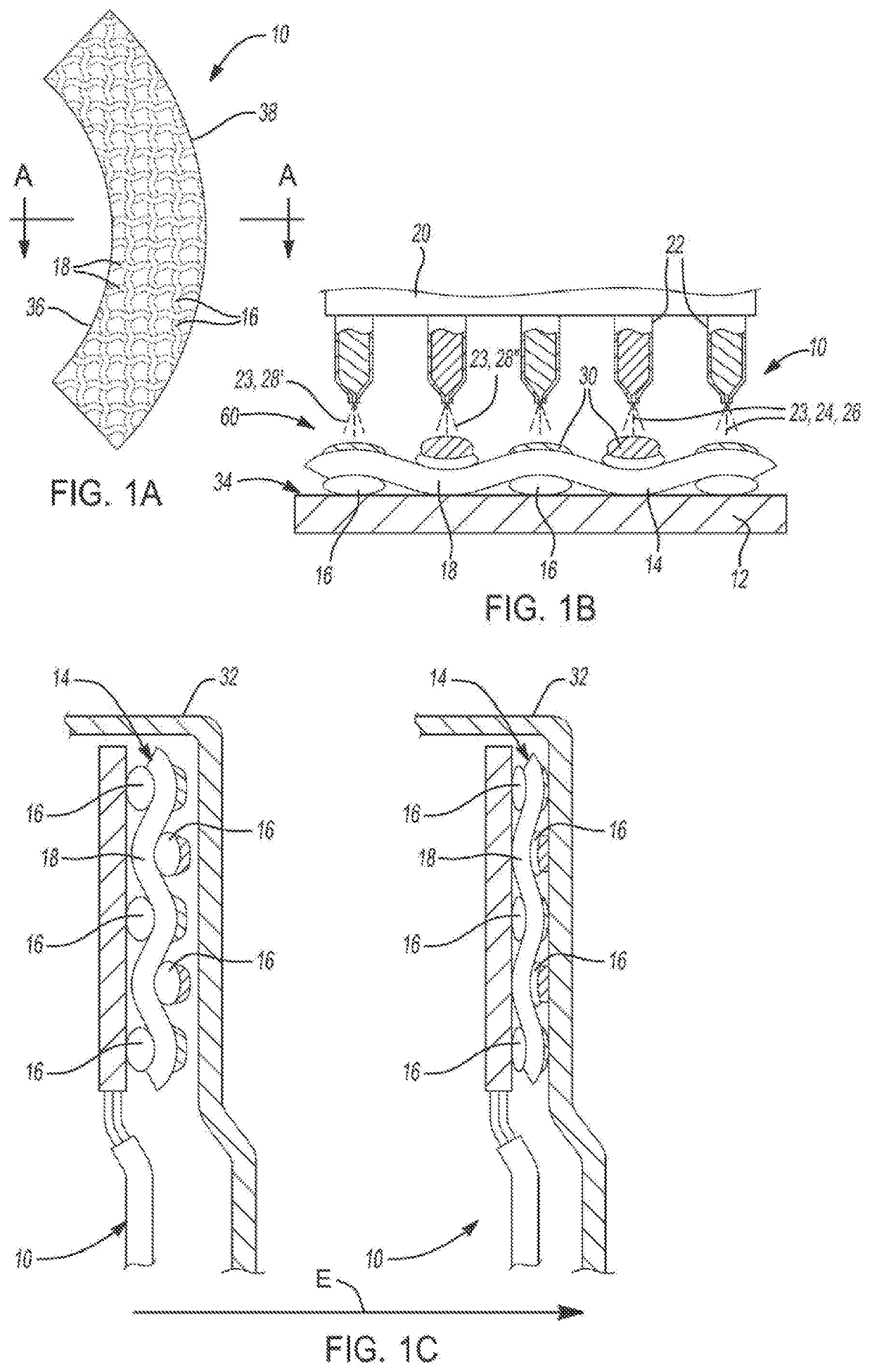

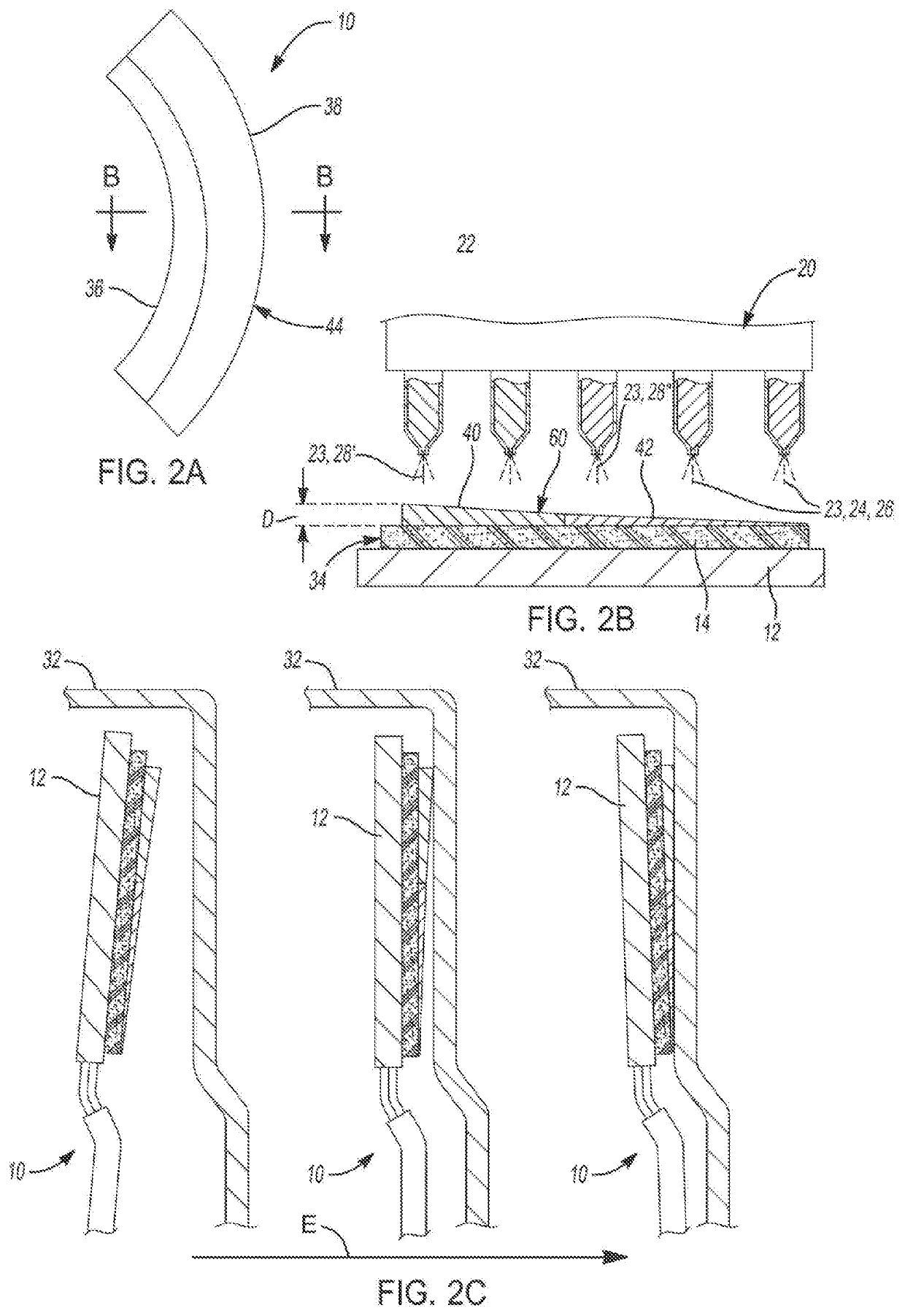

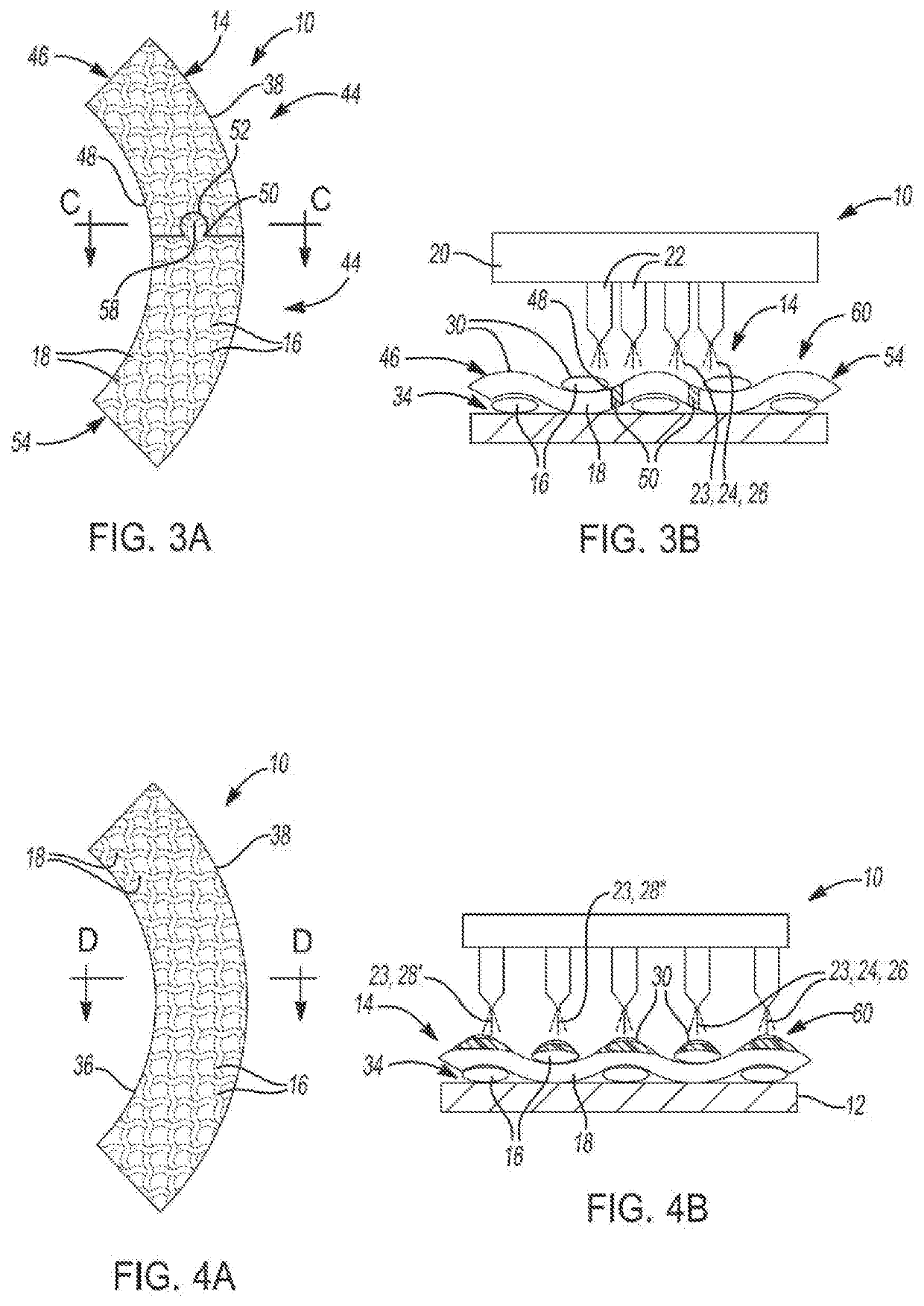

[0036]The following description is merely exemplary in nature and is not intended to limit the present disclosure, application, or uses.

[0037]Friction-disc clutch mechanisms are commonly used at a variety of locations throughout a motor vehicle's powertrain to transfer motive power between a driving shaft and a driven shaft. The operation of such clutch mechanisms generally includes pressing together a pair of opposed clutch plates in which one plate has a high-friction contact surface and the other plate has a relatively smooth contact surface. The forceful engagement between the high friction plate and the smooth plate interlocks the plates together and causes both plates to rotate in unison to achieve a desired power transfer. Under certain clutch operating conditions, however, the constant engagement and disengagement of the plates can be approximated by a stick-slip phenomenon in which the plates skid against one another as opposed to cleanly and crisply engaging and disengagin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com