Method and apparatus for producing container, cell culture vessel, method for culturing cells, method for producing cell culture vessel, and apparatus for producing cell culture vessel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

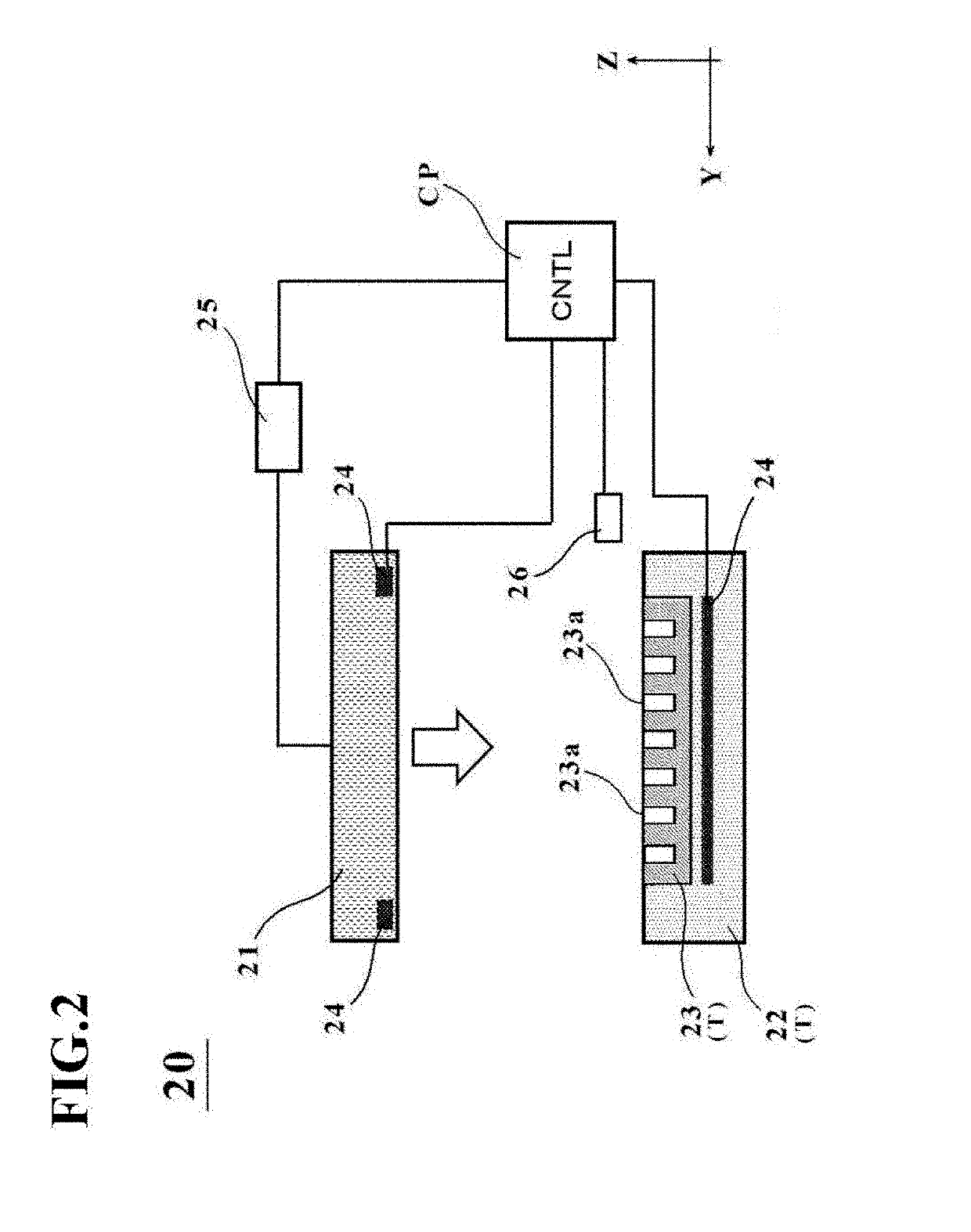

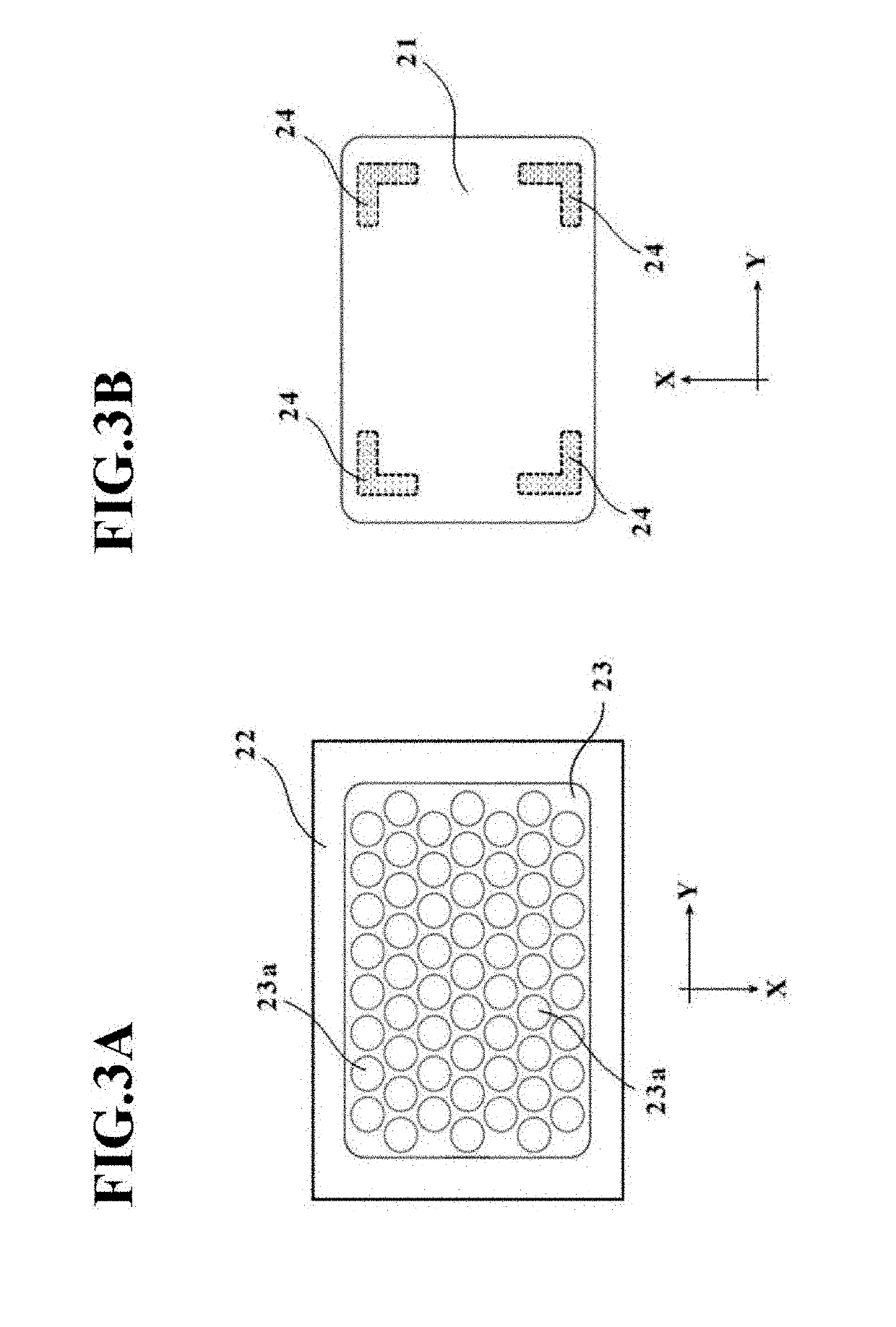

first embodiment

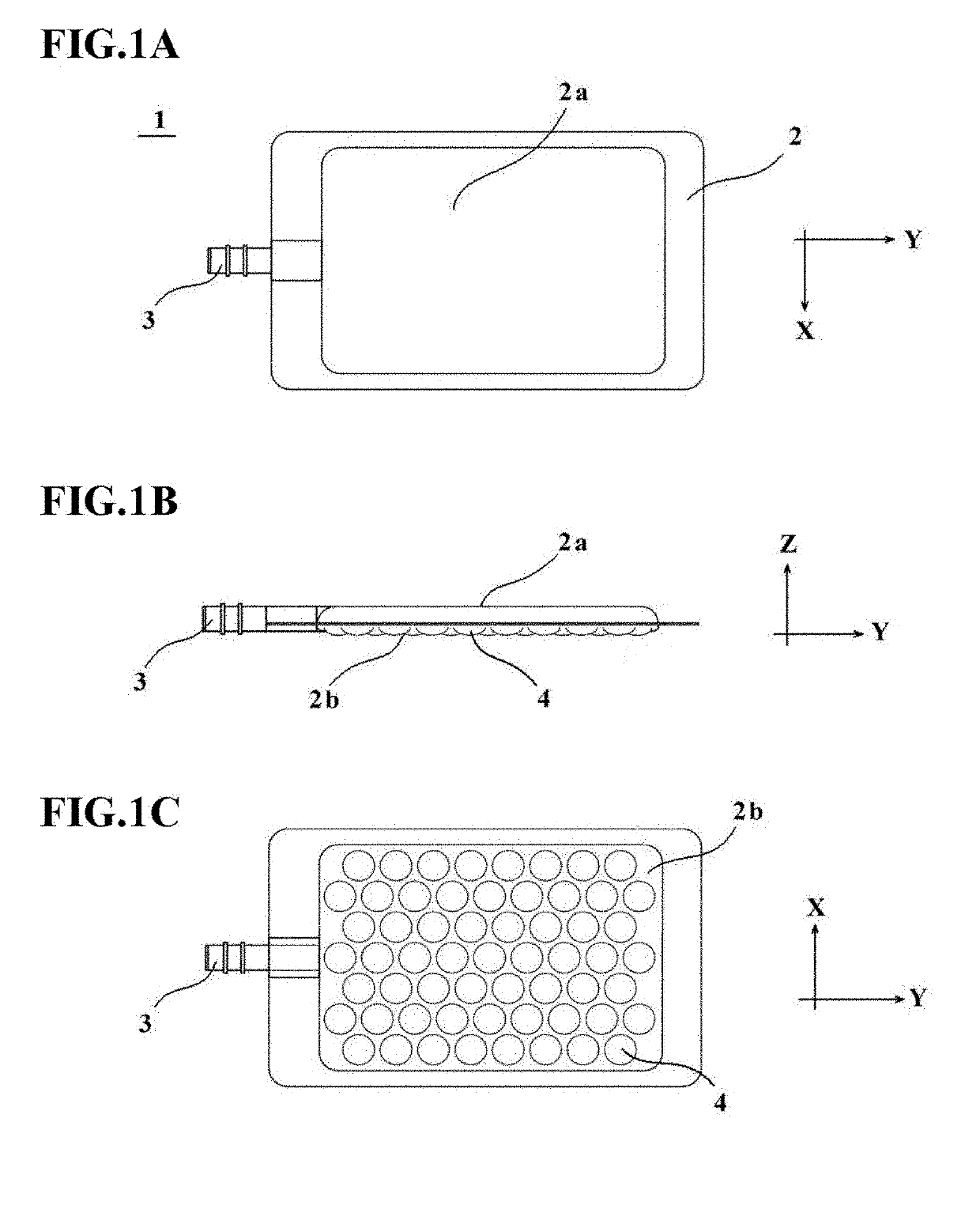

[Cell Culture Vessel 1]

[0062]A cell culture vessel 1 depicted in FIGS. 1A to 1C has a plurality of depressions in a bottom wall, and includes a vessel main body 2 and a charge / discharge port 3. The vessel main body 2 is formed of a known plastic film having gas permeability, and the charge / discharge port 3 is formed of a tubular member through which culture medium, cells, and the like can flow.

[0063]The vessel main body 2 is sealed at a peripheral edge portion thereof, has a bulge shape protruding in a plateau shape on the side of a top wall 2a thereof, and is formed such that the top wall 2a formed as a flat wall is inclined at an edge thereof to extend to the peripheral edge portion. In addition, the vessel main body 2 includes, in a bottom wall 2b thereof, depressions 4 to be used as cell culture portions. At least one depression is required although the plurality of depressions 4 is included in this embodiment. No particular limitation is imposed on the size of the vessel main b...

second embodiment

[0102]A second embodiment of the present invention will next be described with reference to FIGS. 6 to 8.

[0103]A manufacturing apparatus 30 for the cell culture vessel in the second embodiment is different from the manufacturing apparatus 20 in the first embodiment, for example, in that the vessel support member 23 includes a suction channel 23b, a suction device 27 is included, and temperature control devices 28 are also included.

[0104]Therefore, these differences from the first embodiment will hereinafter be described primarily, and components with the same configurations or functions as in the first embodiment will be identified by the same signs as in the first embodiment, and their description will be omitted as desired (this will equally apply to other embodiments and modifications to be described later).

[0105]The manufacturing apparatus 30 will be described as a configuration including both the suction device 27 and the temperature control devices 28 in this embodiment, but t...

third embodiment

[0127]A third embodiment of the present invention will next be described with reference to FIG. 9.

[0128]A manufacturing apparatus 40 for the cell culture vessel in the third embodiment is different from the manufacturing apparatus 20 in the first embodiment, for example, in that the placement stage main member 22 on which the vessel support member 23 is not mounted serves as a placement stage T and through-holes 22a are formed as substitutes for the concave portions 23a in the placement stage T. In this embodiment, the through-holes are not necessarily required and desired holes other than the through-holes may be formed in the placement stage T.

[0129]In other words, the manufacturing apparatus 40 for the cell culture vessel as depicted in FIG. 9 is configured including the placement stage main member 22 with the through-holes 22a formed therein. The through-holes 22a correspond to the concave portions 23a in the first embodiment, and have a shape extending through the placement sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gas permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com