Semiconductor treatment composition

a technology of semiconductors and compositions, applied in the direction of lapping machines, other chemical processes, polishing compositions, etc., can solve the problems of affecting the performance of the polishing machine, the damage of the polishing surface, and the contaminated surface of the polishing waste, so as to improve the efficiency and reduce the damage applied, the effect of excellent filtration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

application example 2

[0011]The concentrated semiconductor treatment composition according to Application Example 1 may be used in a 1 to 500-fold diluted state.

application example 3

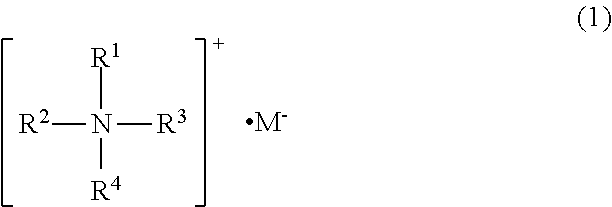

[0012]According to a second aspect of the invention, there is provided a semiconductor treatment composition including potassium, sodium and a compound A represented by the following general formula (1), and being used without being diluted,

[0013]the semiconductor treatment composition having a potassium content MK (ppm) and a sodium content MNa (ppm) that satisfy MK / MNa=1×10−1 to 1×104:

wherein each of R1 to R4 is a hydrogen atom or an organic group, independently, and M− is an anion.

application example 4

[0014]The semiconductor treatment composition according to any one of Application Examples 1 to 3 may have a viscosity less than 5 mPa·s at 25° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com