Method of manufacturing press polymer-bonded explosive using polymer emulsion and press polymer-bonded explosive manufactured using the same

a technology of press polymer and polymer emulsion, which is applied in the direction of explosives, nitrated explosive compositions, weapons, etc., can solve the problems of reducing the efficiency of the process, and reducing the production time. , to achieve the effect of reducing costs, maximizing process efficiency, and shortening the manufacturing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

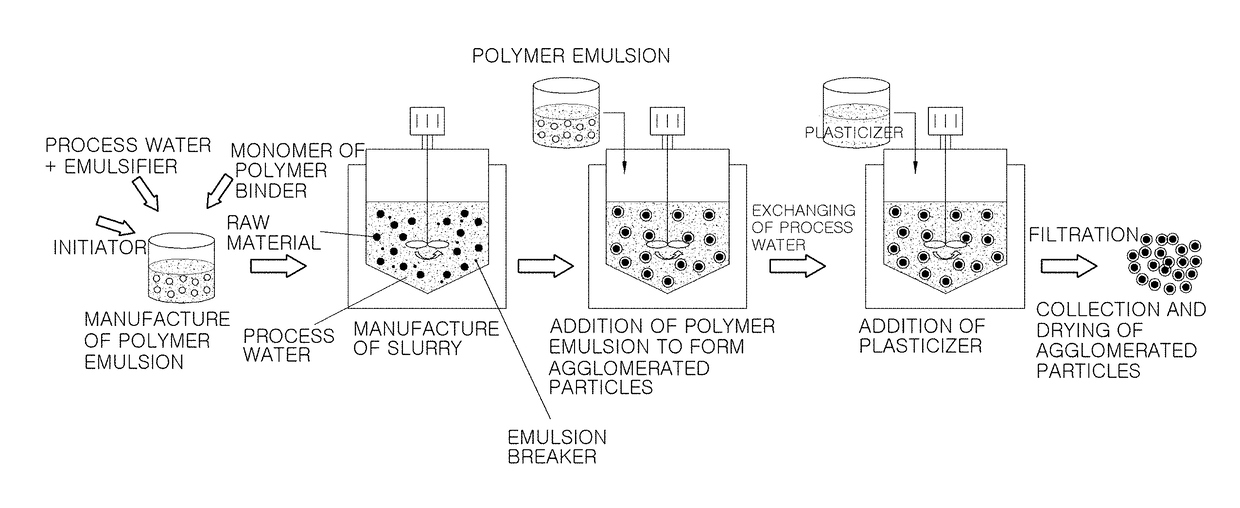

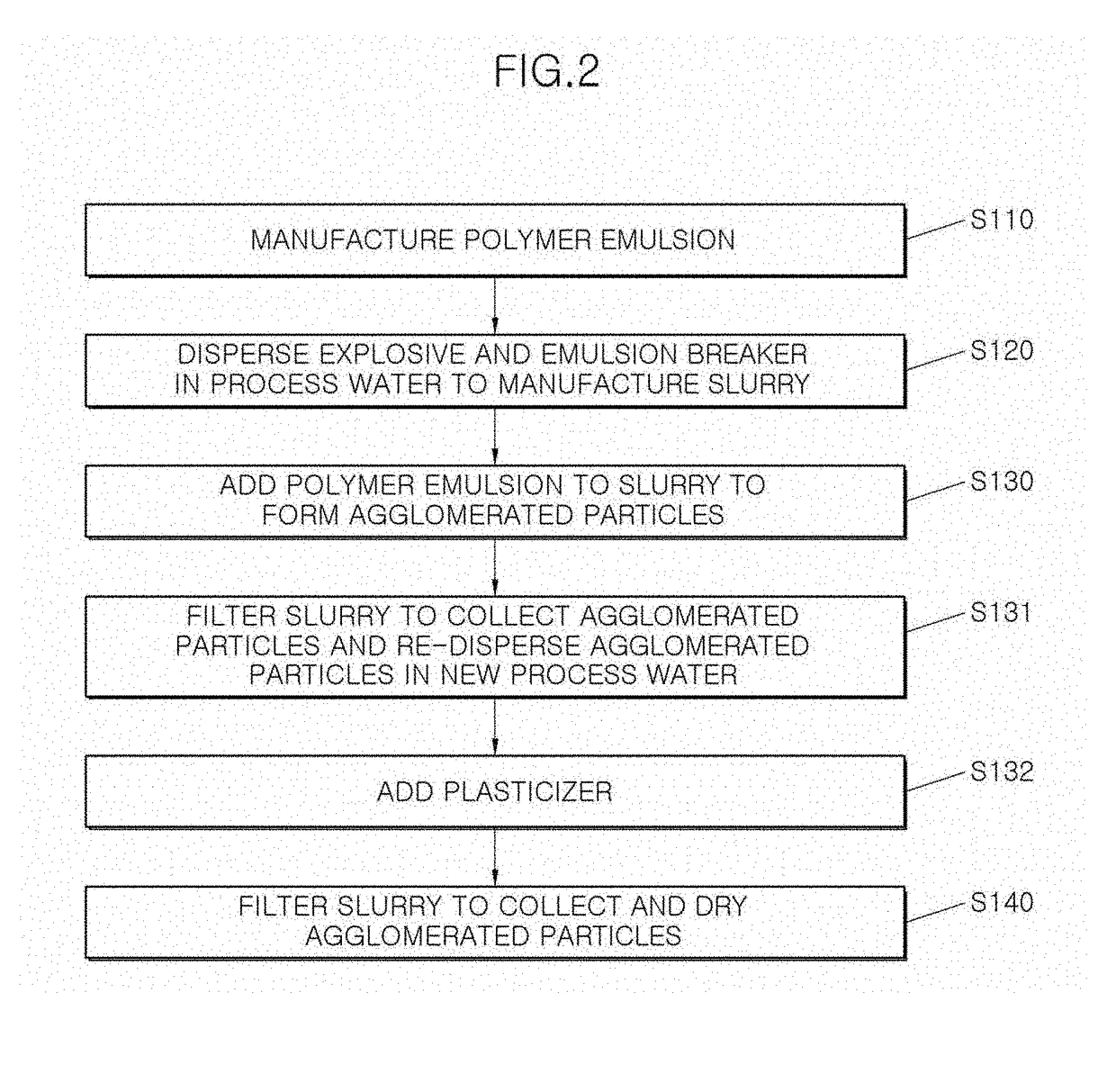

[0070]1.24 g (0.0043 mol) of sodium dodecyl sulfonate, which was an emulsifier, 156 g (1.217 mol) of butyl acrylate, which was a monomer of a polymer binder, and 52 g (0.52 mol) of ethyl acrylate were added to 800 g of a process water on the basis of a 25-liter batch, and were agitated for 1 hour. Thereafter, 0.52 g (0.0019 mol) of potassium persulfate, which was an initiator, was added at a temperature of about 80 to 90° C., and a polymerization reaction was then performed at a temperature of 75° C. for 5 to 10 hours, thus manufacturing a polymer emulsion (S110). Thereafter, 3600 g of RDX (Hanwha Co., Ltd.) and 80 g of calcium chloride (CaCl2), which was an emulsion breaker, were added to 20000 g of process water in a 25-liter reactor, and were agitated at a temperature of 25° C. for 10 minutes, thus manufacturing a slurry. Thereafter, 400 g of the manufactured polymer emulsion (the amount of the included polymer binder was 80 g) was added to the manufactured slurry to thus form ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com