Nanoemulsion synthetic red blood cells having sequentially formed calcium phosphate coating and preparation method thereof

a technology of calcium phosphate coating and synthetic red blood cells, which is applied in the direction of coating, capsule delivery, microcapsules, etc., can solve the problems of increasing production costs, complex preparation process, and purified hemoglobin isolated from red blood cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

Phosphate-Coated Nanoemulsion

[0060]Soy lecithin and perfluorooctyl bromide (PFOB) were respectively purchased from Avanti Polar Lipids, Inc. (Alabaster, Ala.), and Oakwood Chemical, Inc. (Alabaster, Ala.). Packed red blood cells (RBCs) were obtained from the University Hospital Blood Bank at the University of Utah. The RBCs were washed three times with normal saline before being hemolyzed with a hypotonic phosphate buffer. After centrifugation, a supernatant of hemoglobin solution was obtained.

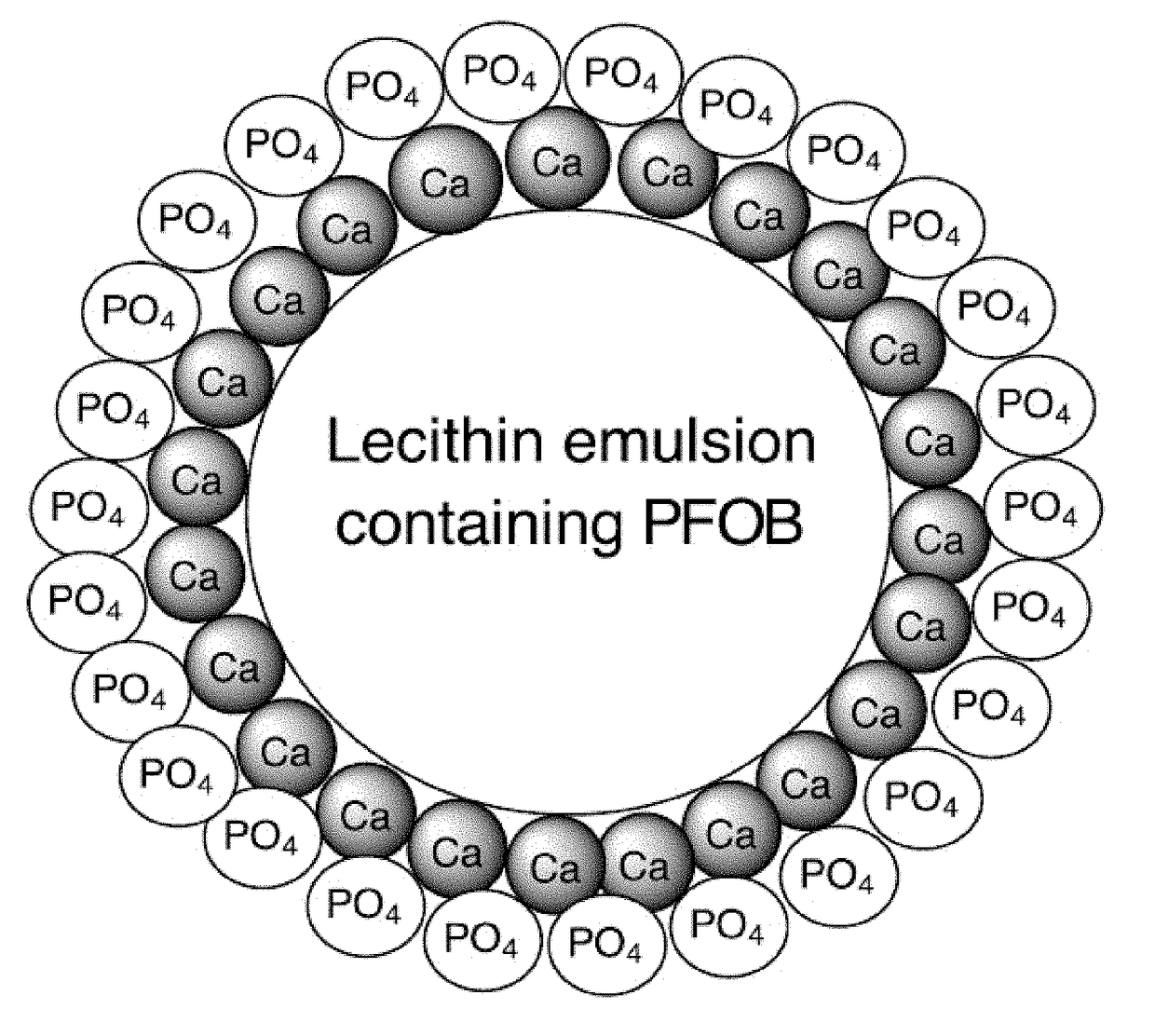

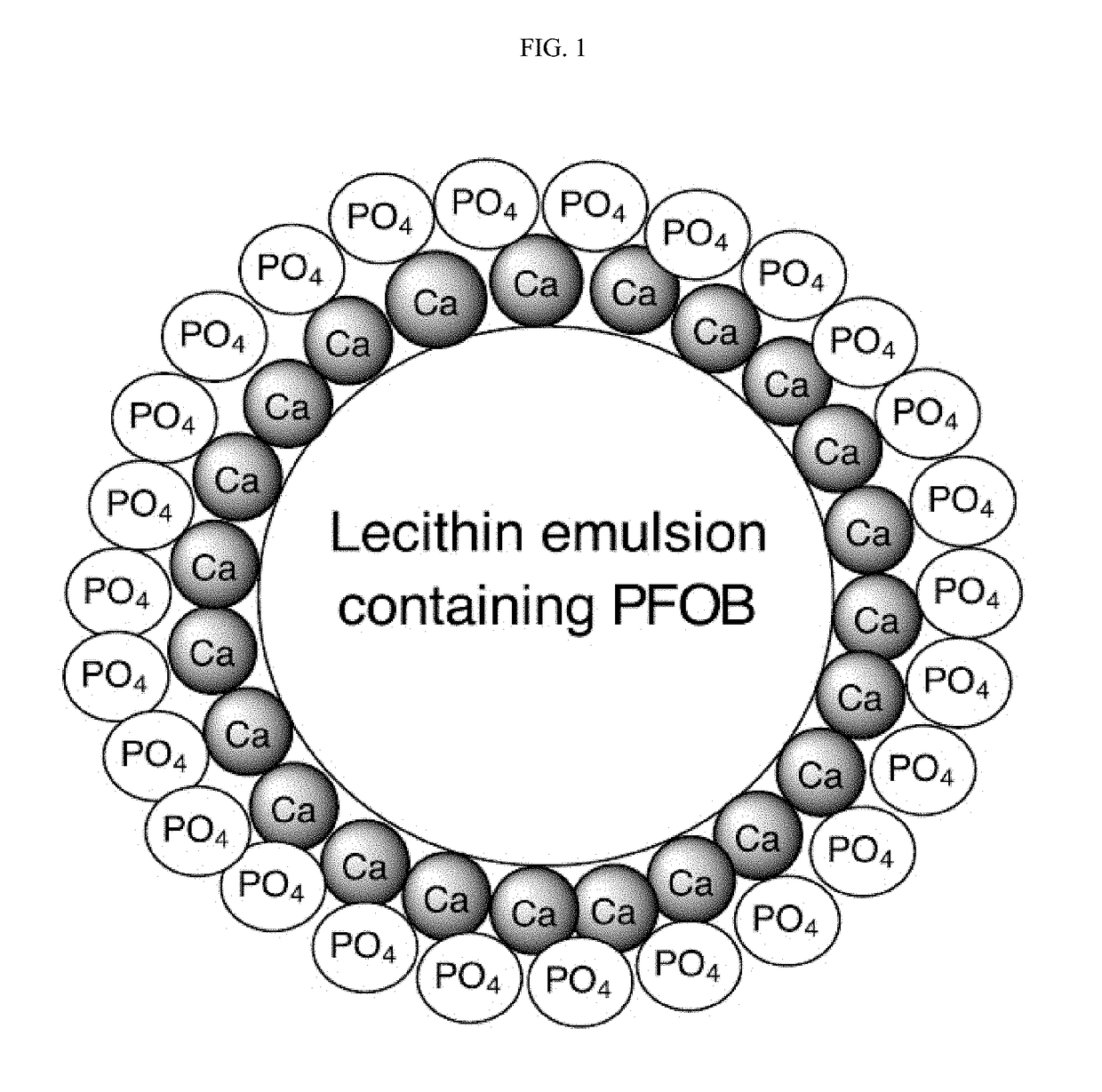

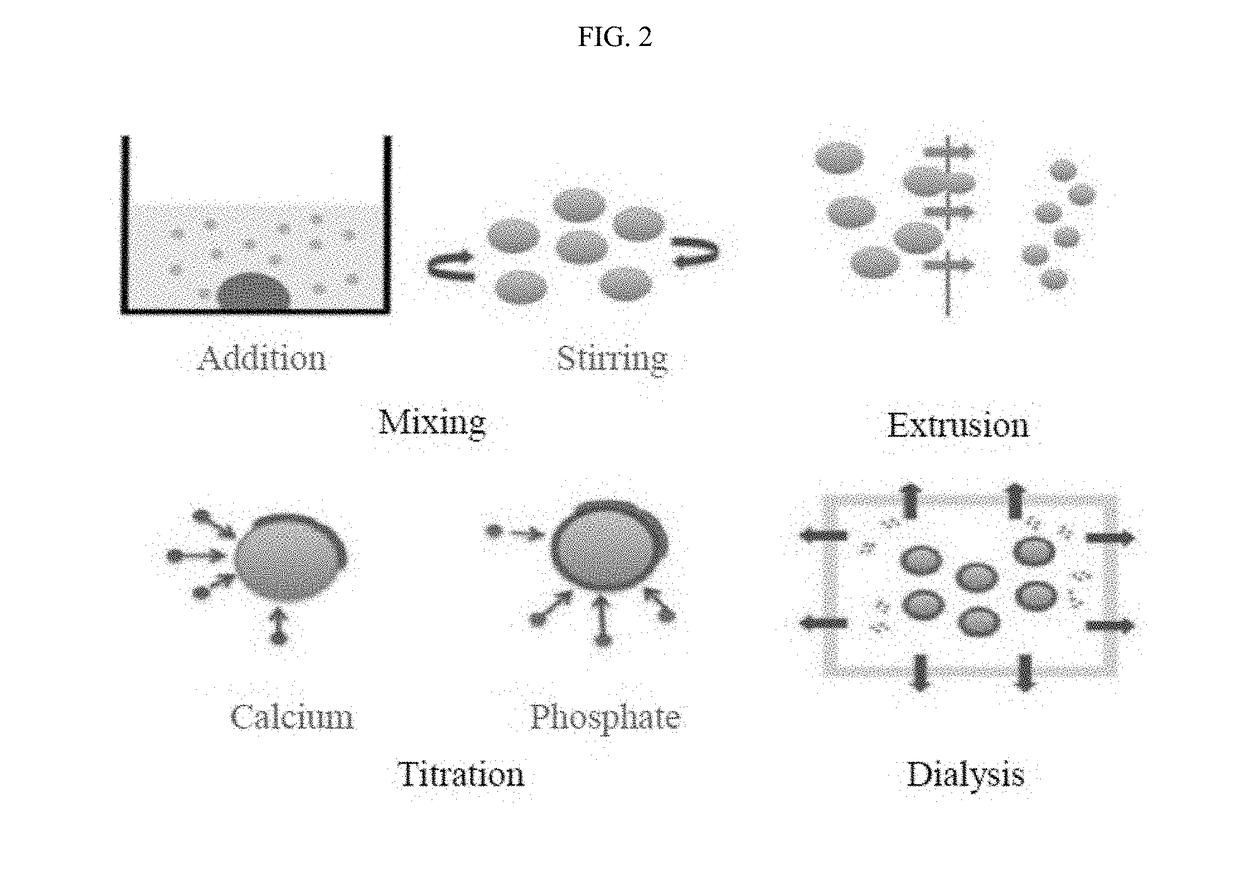

[0061]To synthesize an oil-in-water nanoemulsion, soy lecithin (1.1 mg / g) was added to PFOB (2 vol %) and deionized water. The sample was stirred at 1200 rpm for 30 minutes at room temperature and extruded through a 200-nm pore size membrane, seven times, at 150 psi. A titration method was utilized to optimize the surface charge of the emulsion with hydrochloric acid (HCl, 0.1 M) and to observe the ionic affinity between calcium and phosphate ions; calcium chloride (CaCl2, 3.0 mM, pH 9) and ph...

example 1

on of the Characteristics and Stability of Nanoemulsion

[0062]The particle size and zeta-potential were characterized by Zetasizer Nano ZS (Malvern, UK). Transmission electron microscope (FEI Tecnai™ TEM) was utilized for morphology observations, where the emulsion was prepared with a negative stain, uranyl acetate (47 mM, 10 μL). The coated and uncoated emulsions (with and without CaP) were observed at 80 keV.

[0063]The pH titration test clearly supported the notion that the phosphate group in soy lecithin was the main site of ion interaction. Since the amine group in soy lecithin is a quaternary amine group having three methyl groups and one R group, it is not pH active. The phosphate in the head group of soy lecithin was the only group that was expected to react with a proton. The zeta-potential is a good indicator of the dispersion stability. Near zero mV results in minimal electrostatic repulsion between particles, so the greater absolute value of zeta-potential, the better the s...

example 2

on of the Rate and Amount of Oxygen Release

[0072]Packed red blood cells (RBCs) were hemolyzed with a hypotonic phosphate buffer (5 mM, pH 7.4) to obtain a hemoglobin solution whose concentration was measured by UV-Vis spectroscopy. After determining its raw concentration, the solution was adjusted to 120 μM and pH 7.2. Deoxygenated hemoglobin (Hb) was formed by purging the solution with nitrogen gas until the dissolved oxygen probe was reading zero. In order to measure the rate of oxygen release, Hb and a stopped-flow apparatus (American Instrument Co, Inc, Silver Spring, MY) with a spectrophotometer (Beckman, National Technical Laboratories) were utilized. Four different samples were produced, each with a different number of calcium and phosphate layers. The apparatus was a light-beam path of 4 mm and the slit (0.82 mm). The transmittance of the mixture was recorded using LabView software. By monitoring the change of transmittance at 550 nm, it was shown that Hb was changed to oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com