Method and device for controlling and/or monitoring the function of a secondary air supply in an emission control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

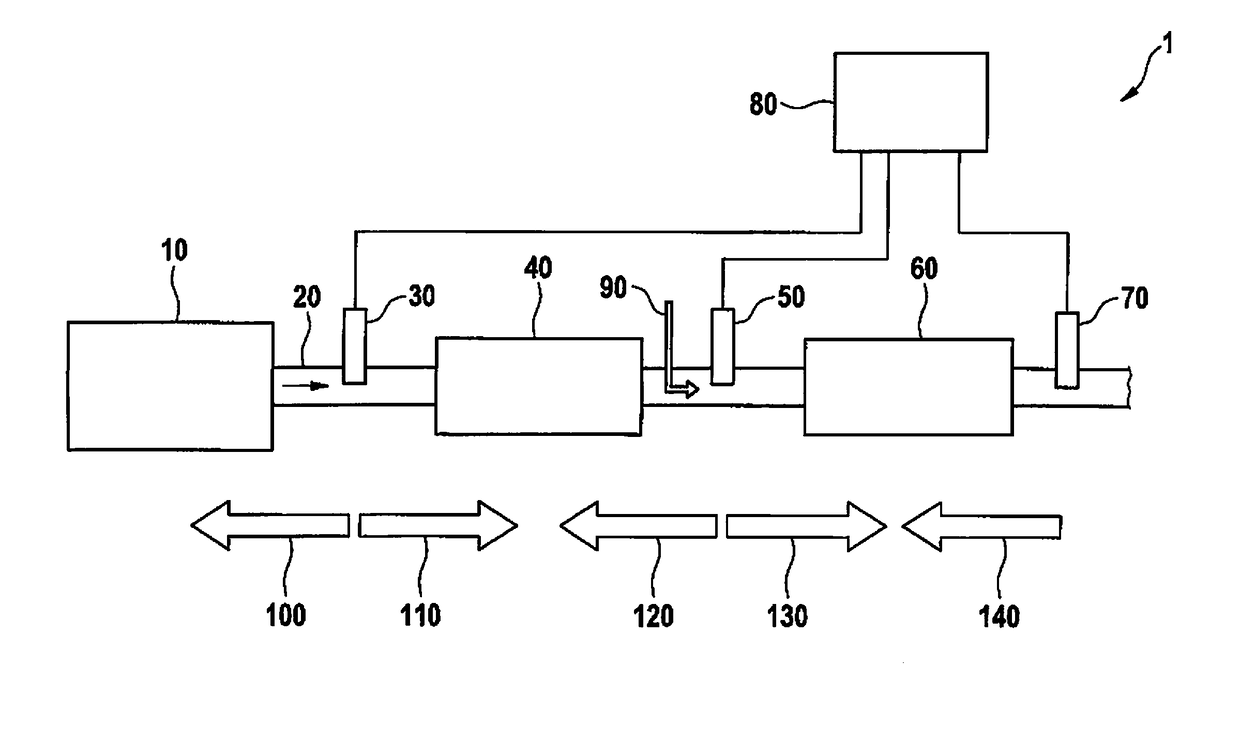

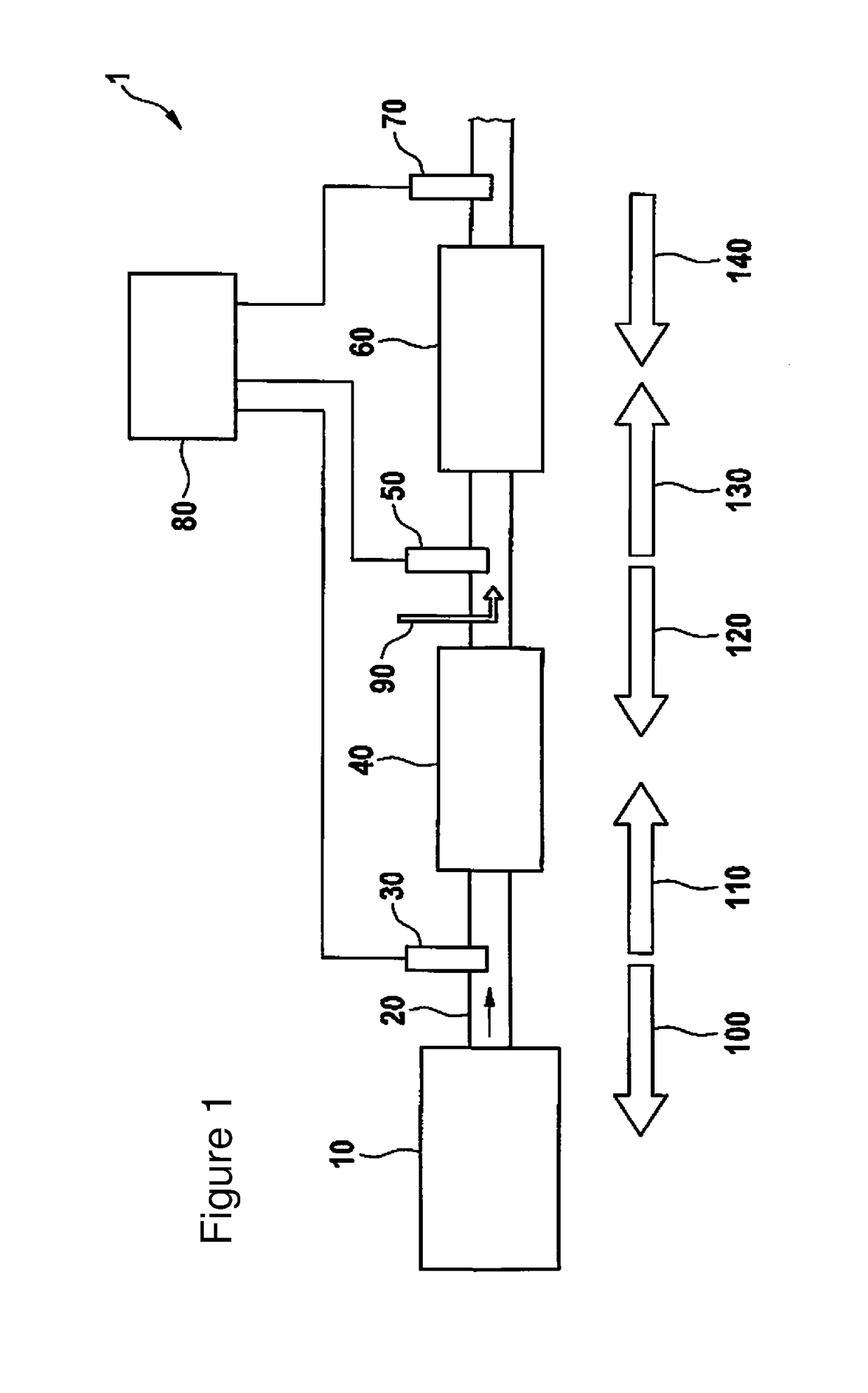

[0032]The FIGURE shows in a schematic representation an internal combustion engine 1 that includes an engine block 10, an exhaust duct 20, a lambda probe 30 that is, with respect to the direction of flow of exhaust gas, downstream of the engine block 10 and that is, in an example embodiment, implemented as a wide-band lambda probe, and a first catalytic converter 40 situated downstream of the lambda probe 30. Lambda probe 30 makes possible lambda control 100 and is used for a first balancing 110 for diagnosing the storage capacity of the first catalytic converter.

[0033]The internal combustion engine 1 further includes, downstream from first catalytic converter 40, a first two-point lambda probe 50 used for catalytic converter diagnosis-tracking control and for breakthrough detection for the diagnosis of first catalytic converter 40. The internal combustion engine 1 further includes a second catalytic converter 60 downstream of the first two-point lambda probe 50. The first two-point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com