A drainage-dehydration control method of a multi-drum washing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

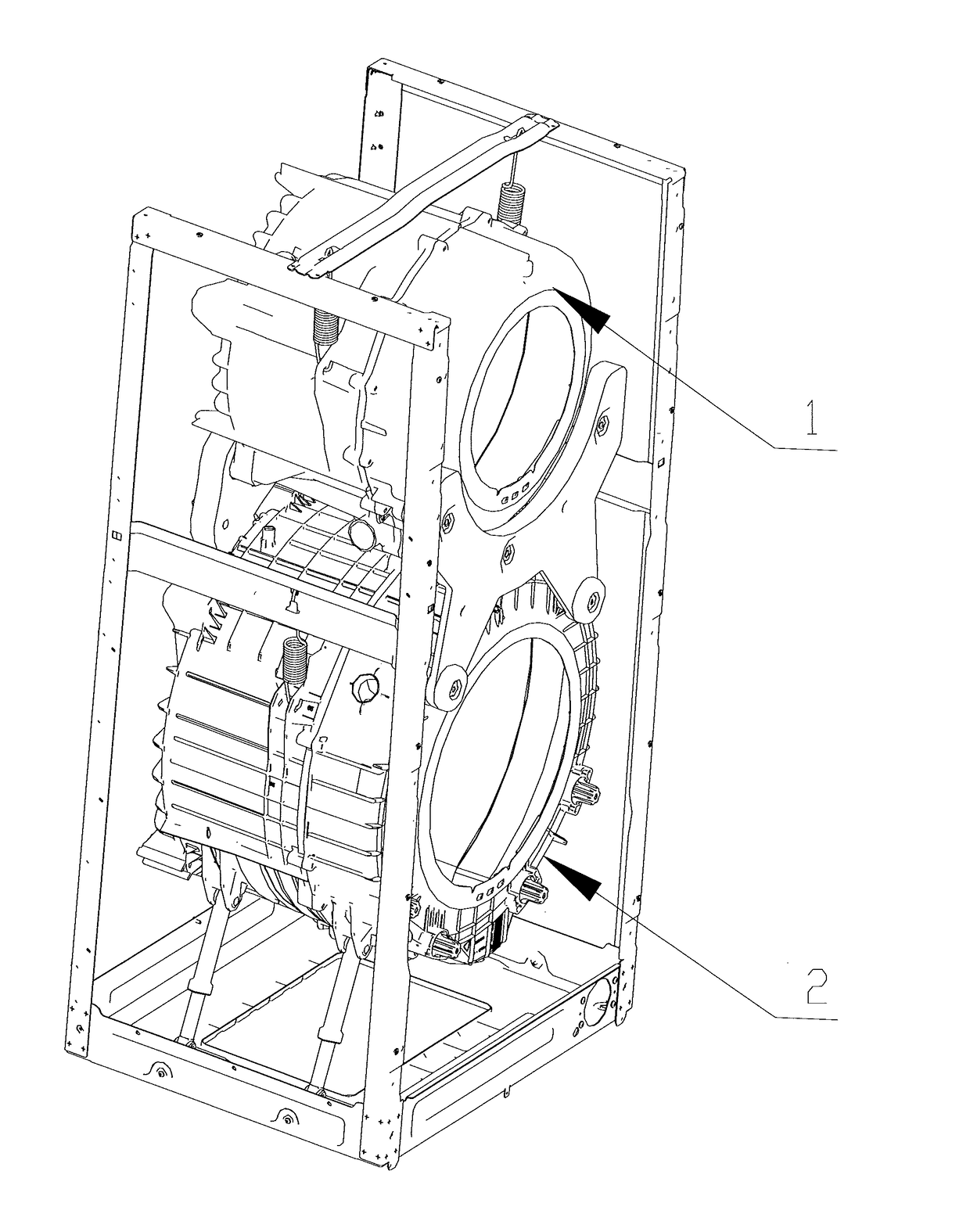

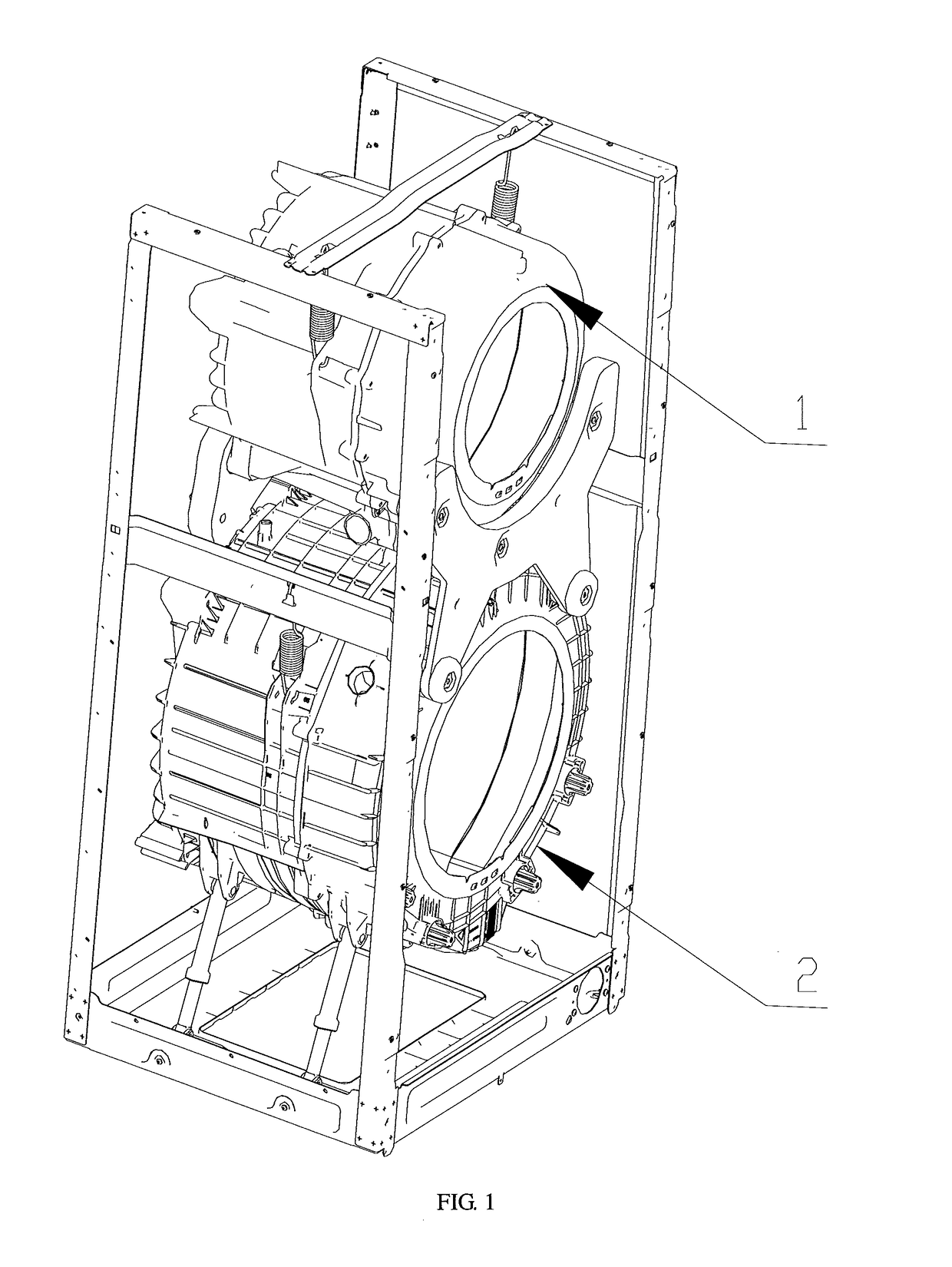

Image

Examples

embodiment 1

[0040]A drainage-dehydration control method of a multi-drum washing machine in the embodiment is introduced as follows:

[0041]Before the first washing drum executes a drainage procedure, it is judged whether the second washing drum is executing a drainage procedure or a dehydration procedure. If yes, the first washing drum continues to execute a washing procedure or a rinse procedure, or suspends executing drainage or dehydration procedure until the dehydration procedure of the second washing drum is completed. If no, the first washing drum starts the drainage procedure and the dehydration procedure.

[0042]In the embodiment, before the first washing drum starts the drainage procedure, the second washing drum is executing the drainage procedure, so the first washing drum continues to execute the washing-procedure or the rinse procedure, or suspends executing the draining procedure or dehydration procedure. The first washing drum restarts the drainage procedure and the dehydration proce...

embodiment 2

[0064]As shown in FIG. 3, a drainage control method of a multi-drum washing machine. When the first washing drum reaches the drainage procedure, it is determined whether or not the second washing drum is in a dehydration procedure. If the second washing drum is in the dehydration procedure, the first washing drum waits until the dehydration procedure of the second washing drum is completed, and then drains. The water in the first washing drum plays a role as a counterweight, thus it increases the overall weight of the washing machine to achieve the effect of vibration absorption.

[0065]If the second washing drum is not dehydrating at the moment, it is judged whether to wait until the dehydration is completed, and then to drain. It can avoid the scenario that the second washing drum starts to dehydrate as soon as the first washing drum finished draining water. Under that scenario the water in the first washing drum cannot achieve the effect of vibration absorption, resulting waste.

[00...

embodiment 3

[0085]In the present disclosure, the first washing drum 1 and the second washing drum 2 are communicated with the same inlet pipe through pipe path, and a control device for controlling the flow of water is provided on the pipes. Thus, before the washing process is performed, the washing water can be injected into first washing drum and / or the second washing drum through the water inlet pipe path.

[0086]However, since the inlet water flow rate of the household inlet pipe is constant, when the first washing drum and the second washing drum are supplied with water at the same time, it will cause the occurrence of smaller inlet flow rate and the first washing drum and the second washing drum not reaching the set water level. It also will cause the problem that inlet water flow rate is unstable and the water level of washing water in the first washing drum and the second washing drum cannot be accurately determined

[0087]In order to avoid the above-mentioned situation, the water quantity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com