Gas Turbine Combustor

a technology of gas turbine combustor and combustor body, which is applied in the direction of machines/engines, burner control devices, lighting and heating apparatus, etc., can solve the problems of deterioration of explosion, etc., to secure the reliability and suppress the excessive temperature rise of the structure of the gas turbine combustor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0021](Configuration)

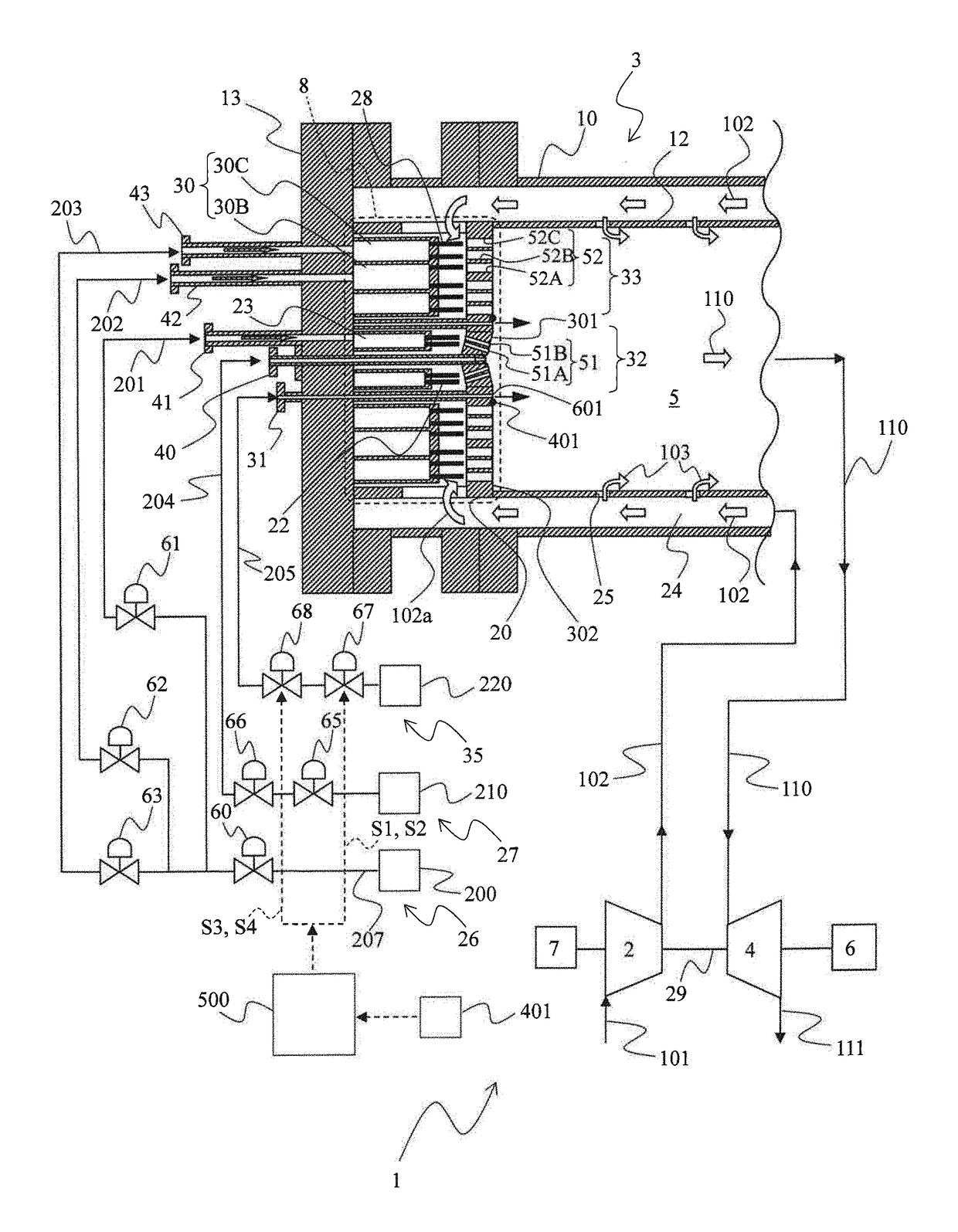

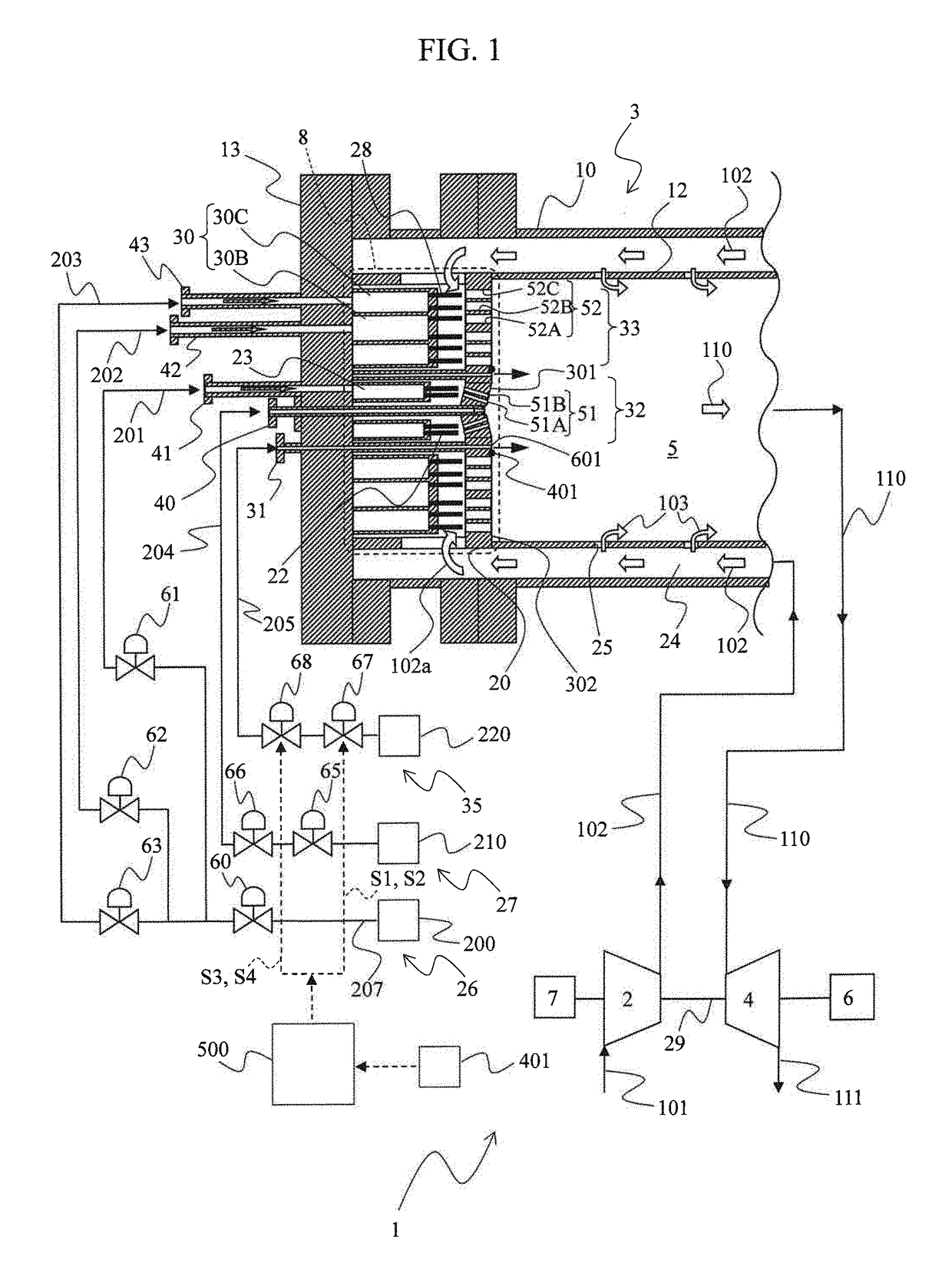

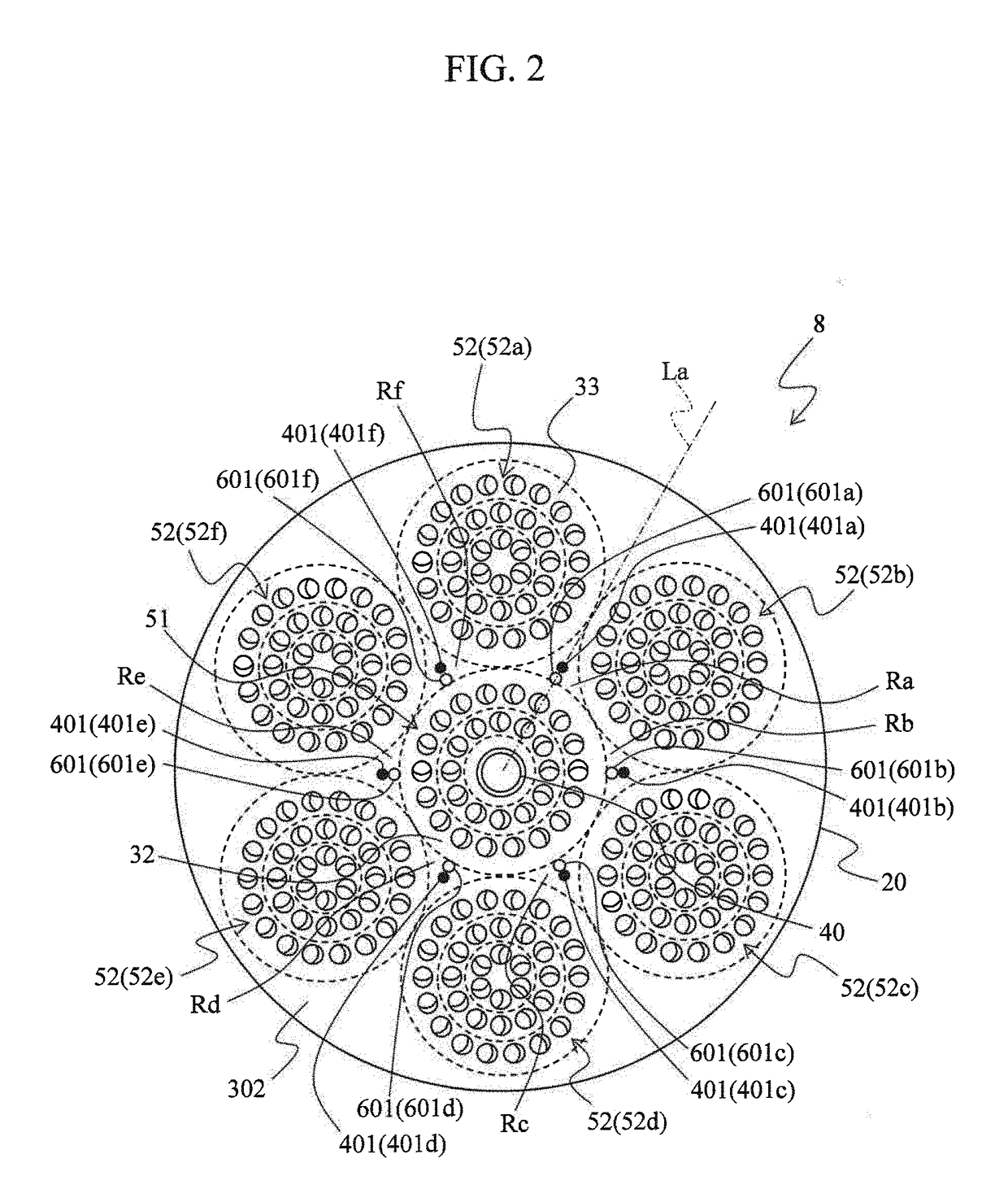

[0023]FIG. 1 is a diagram representing a configuration example of a gas turbine plant applied with a gas turbine combustor (hereinafter, combustor) according to this embodiment. As shown in FIG. 1, a gas turbine plant 1 includes a compressor (an air compressor) 2, a combustor 3, a turbine 4, a power generator 6, and a startup motor 7.

[0024]The compressor 2 is started up by the startup motor 7, compresses air 101 sucked from the atmosphere via an inlet (not shown in the figure) to generate high-pressure compressed air 102, and supplies the compressed air 102 to the combustor 3. The combustor 3 mixes the compressed air 102 supplied from the compressor 2 with fuel supplied from a fuel supplying system 26 (explained below) and burns the compressed air 102 and the fuel, generates high-temperature combustion gas 110, and supplies the combustion gas 110 to the turbine 4. The combustion gas 110 supplied from the combustor 3 expands, whereby the...

second embodiment

[0078](Configuration)

[0079]FIG. 9 is a diagram representing a configuration example of a gas turbine plant applied with a combustor according to this embodiment. In FIG. 9, portions equivalent to the portions in the first embodiment are denoted by the same reference numerals and signs and explanation of the portions is omitted as appropriate.

[0080]This embodiment is different from the first embodiment in that the cooling system 35 further includes a cooling pipeline 206, a cooling nozzle 34, a thermocouple 402, and a cooling hole 602. Otherwise, this embodiment is the same as the first embodiment.

[0081]As shown in FIG. 9, the cooling pipeline 206 branches from the cooling pipeline 205 and connects the coolant supply source 220 and the cooling nozzle 34. The cooling nozzle 34 is connected to the cooling hole 602. Coolant guided from the coolant supply source 220 to the cooling nozzle 34 through the cooling pipeline 206 is injected into the combustion chamber 5 via the cooling hole 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com