Condenser for a steam power plant

a steam power plant and condenser technology, which is applied in steam engine plants, corrosion prevention, lighting and heating apparatus, etc., can solve the problems of steam present in steam turbine condensing, unplanned shutdown states of unforeseeable duration, and power plant operators having to put their power plants into more frequent shutdown states, etc., to reduce evaporation in the hotwell, simple and inexpensive manner, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

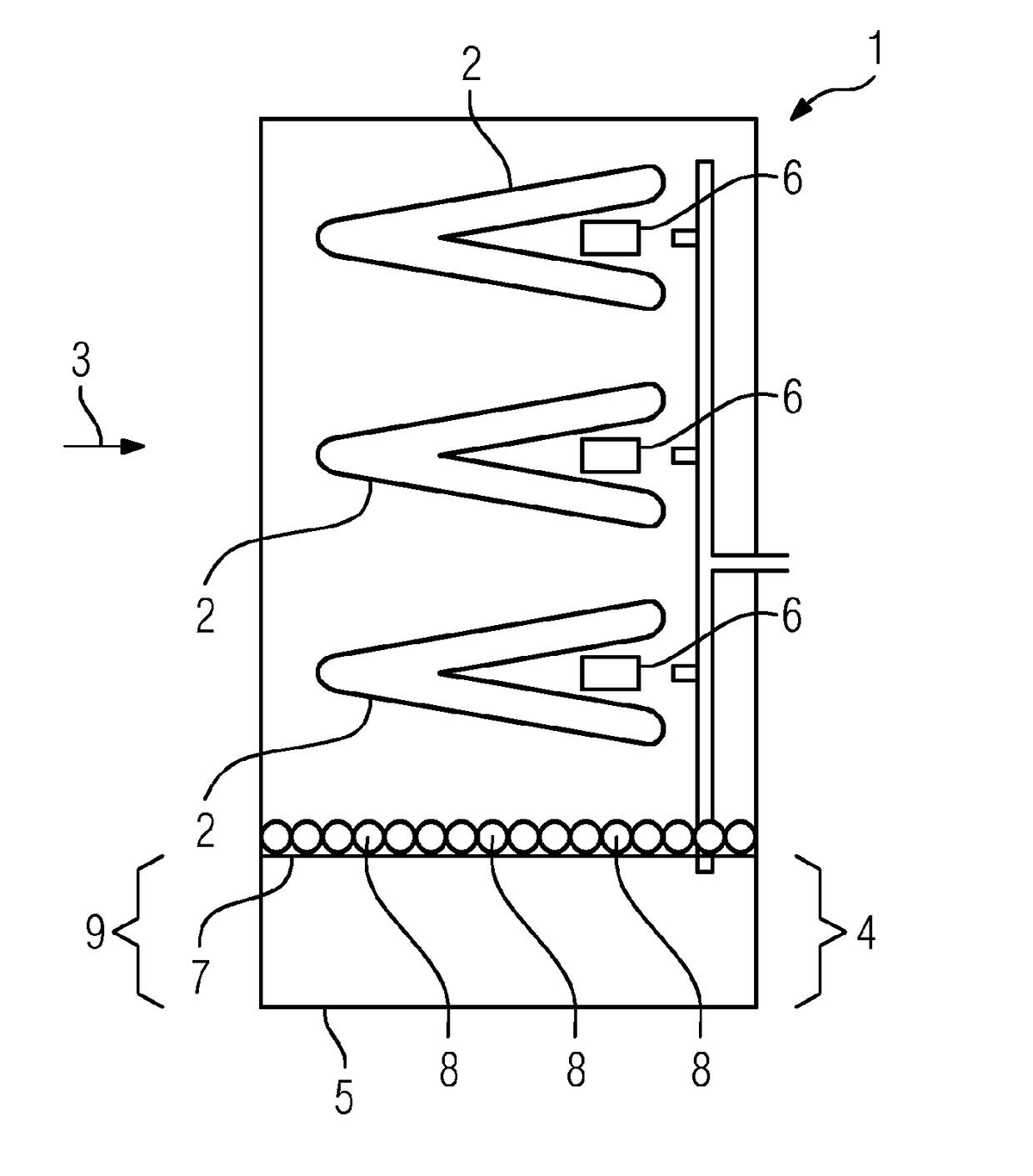

[0030]FIG. 1 shows a cross-sectional view of a condenser 1 for a steam power plant, which is not shown in more detail. The condenser 1 comprises a plurality of tube bundles 2 which are arranged in a steam flow 3. Cooled water flows through the tube bundles 2, which leads to the water vapor from the steam flow 3 condensing on the surfaces of the tube bundles 2 and, as water, coming into a region 4 in which the water collects to form a condensate 5. The steam flow 3 is fluidically connected to a low-pressure turbine section. Furthermore, the condenser 1 comprises air coolers 6 which are arranged in the region of the tube bundles 2.

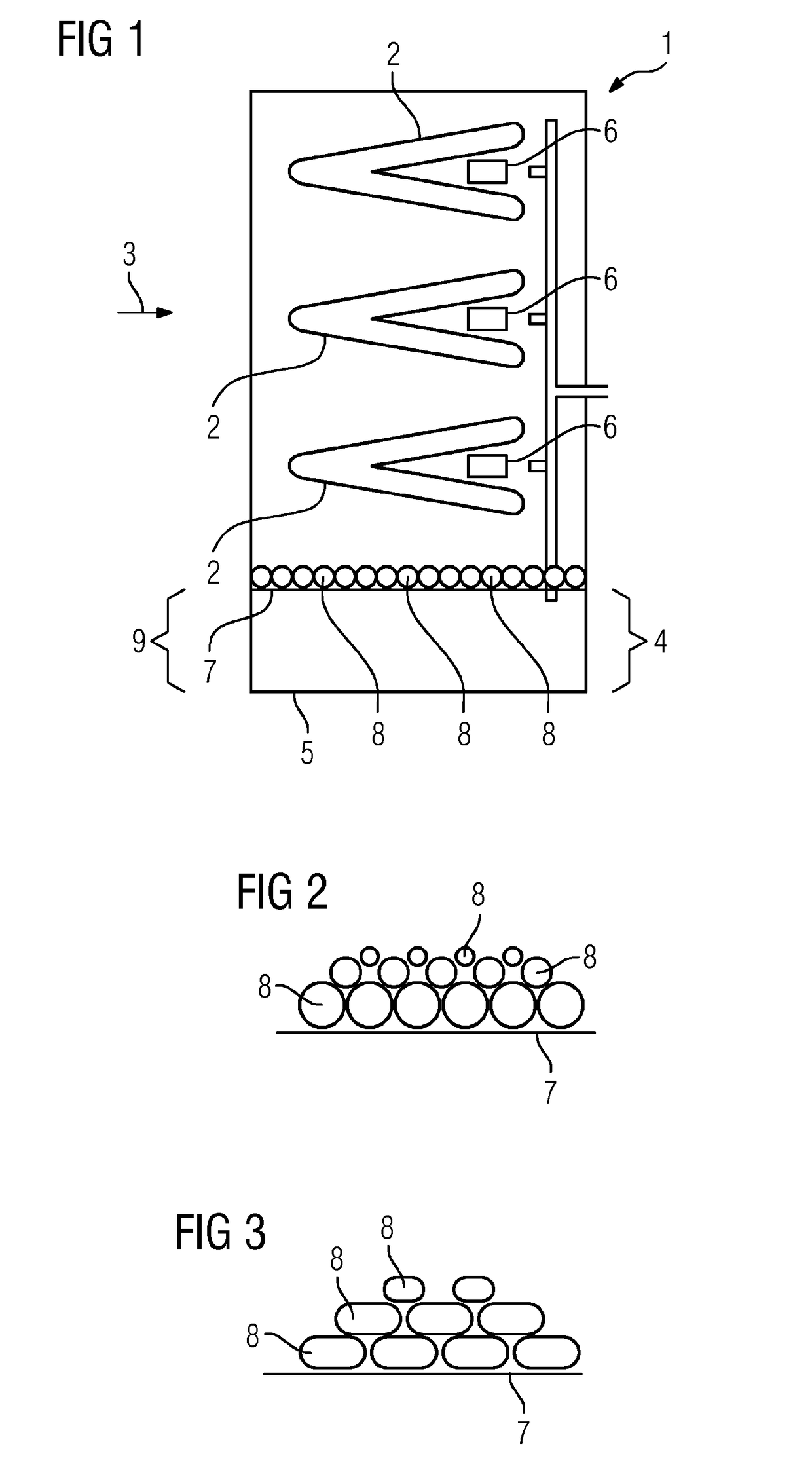

[0031]The condensate 5 forms a condensate surface 7.

[0032]According to the invention, floating bodies 8 are arranged on this condensate surface 7. In FIG. 1, for reasons of clarity, only three floating bodies 8 are provided with the designation 8. These floating bodies 8 wet the condensate surface 7 and consequently reduce the contact area of the condensate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com