Gable assembly for use with a modular watercraft lift cover

a technology for boat lifts and modular boats, which is applied in the field of modular boat lift cover systems, can solve the problems of difficult design, manufacture and installation of boat lift covers for tidal lifts, and the lifts are not perfectly square, and achieves the effect of wide adjustment range and convenient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

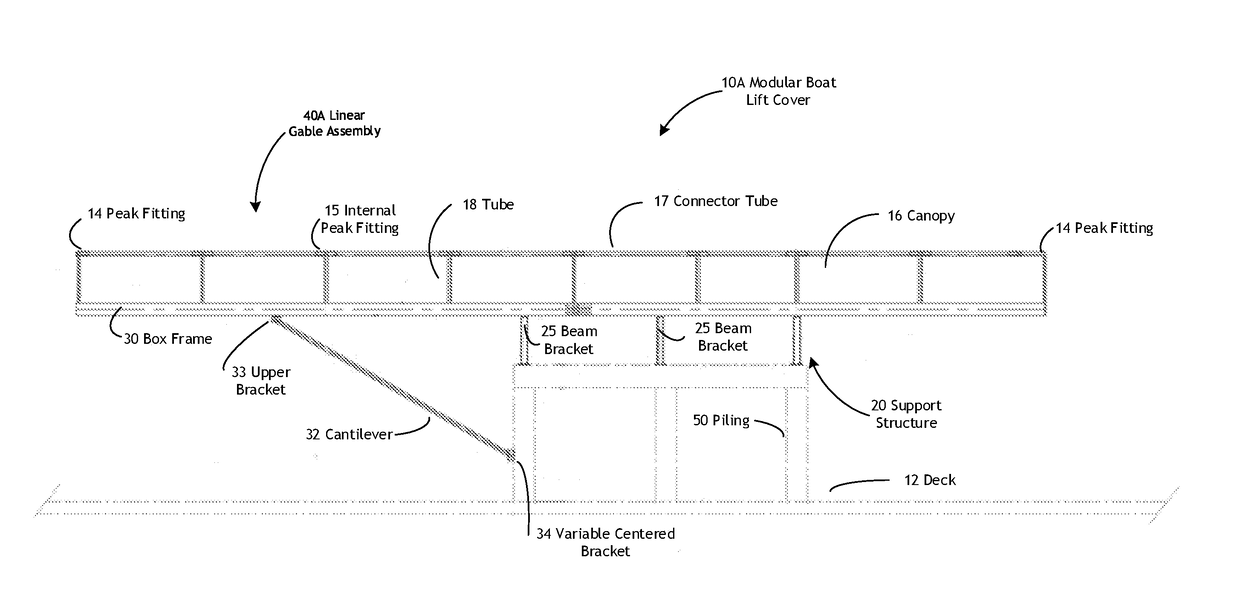

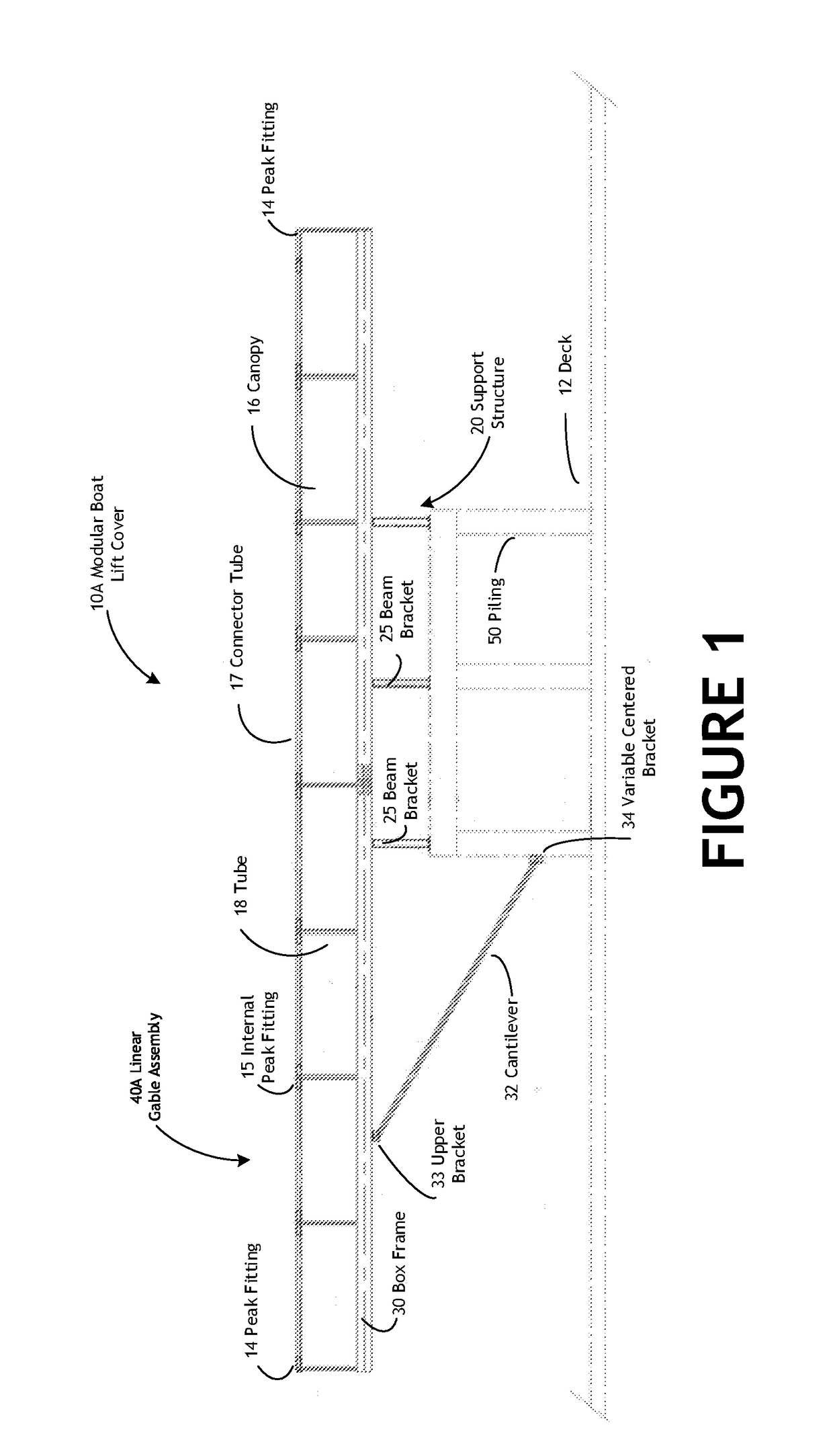

[0066]Referring now to the drawings, FIG. 1 depicts a preferred embodiment of an assembly side view of the modular boat lift cover of the present invention [10A]. The modular boat lift cover of the present invention [10A] comprises a gable assembly [13], a canopy [16], and an adjustable support structure [20] for a watercraft.

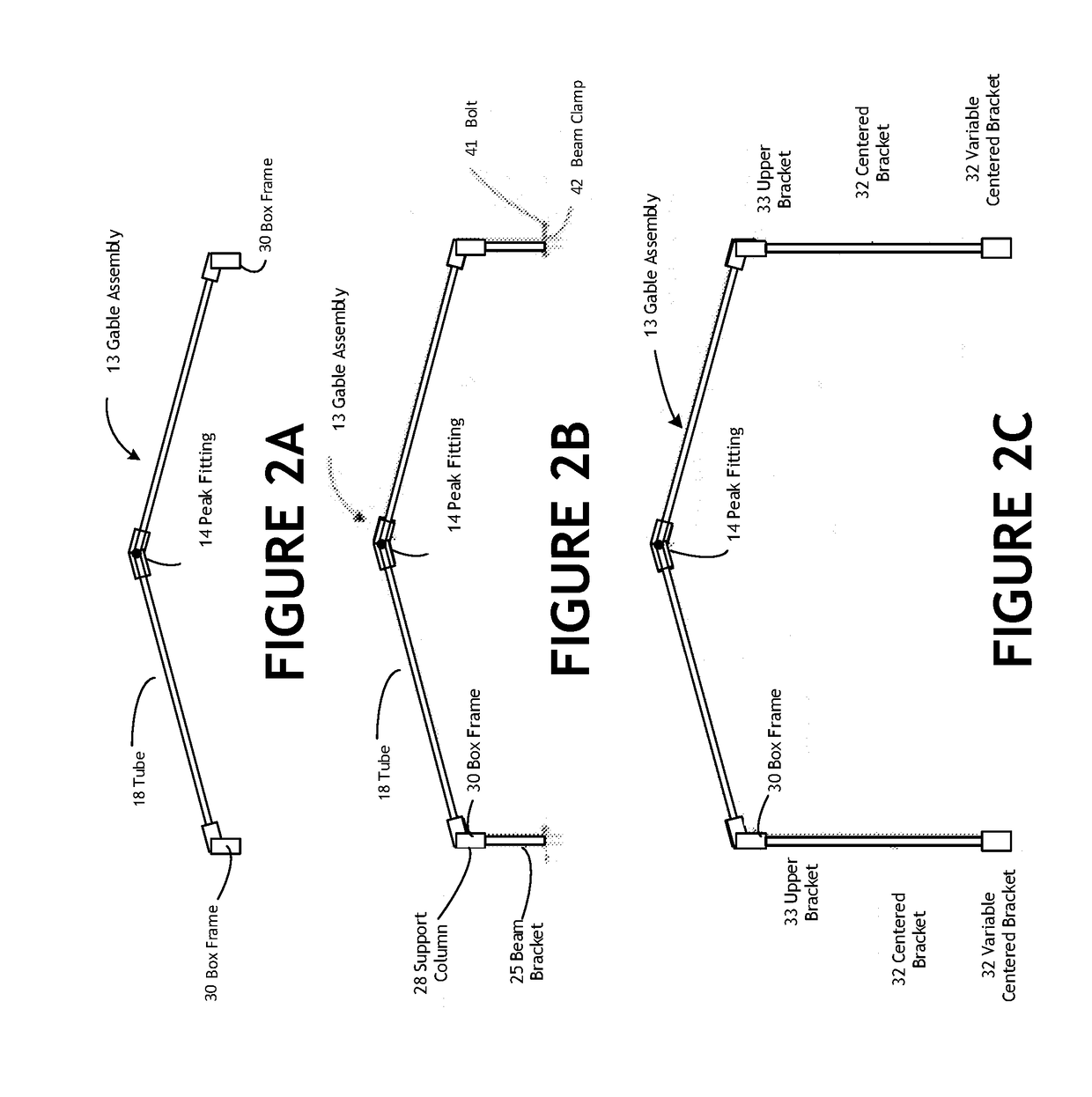

[0067]The gable assembly [13] includes a plurality of end peak fittings [14] and internal peak fittings [15], as further depicted in FIGS. 5A, 5B, 5C, 5D, a plurality of box frame support members [30], and a plurality of tubes [18] securely attaching the end peak fittings [14] and the internal peak fittings [15] to the box frame support members [30]. The box frame support members [30] are preferably horizontally mounted in the gable assembly [13] and cantilevered out from the piling [50] upon which the beam brackets [25] are attached if necessary for applications in which the piling [50] is not arrayed as desired for a given size boat or watercraft. In the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com