Composite Metal Product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

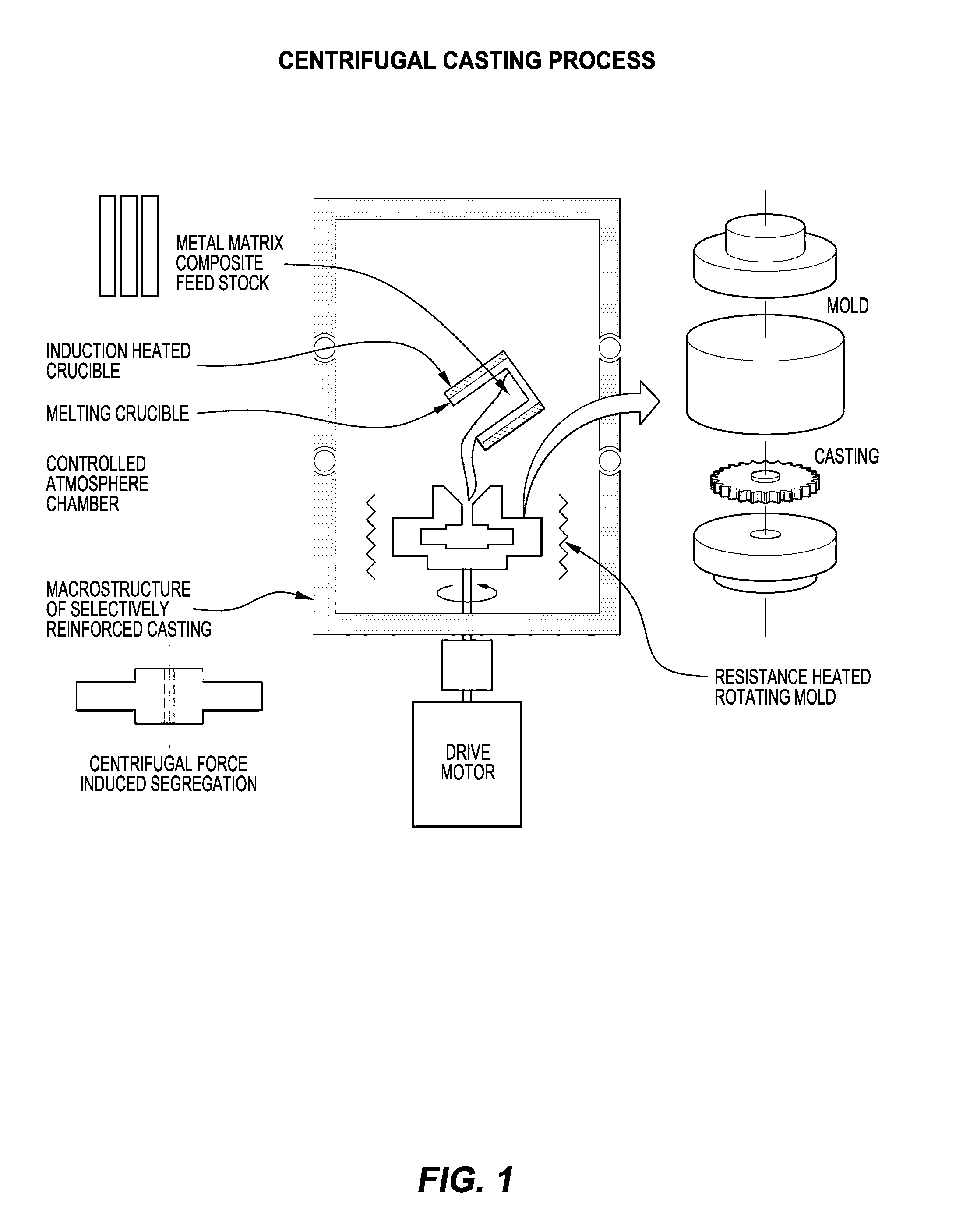

[0120]FIG. 1 was sourced from the internet and illustrates in diagrammatic form the basic steps in a centrifugal casting method.

[0121]These centrifugal casting steps include forming a molten melt and pouring the melt into a suitable mould and rotating the mould about a vertical axis (in the case of the arrangement shown in the Figure) at a required rate of rotation to form a cast product.

[0122]In alternative arrangements, such as the arrangement used to carry out the experimental work described below, the casting mould is positioned horizontally and the mould is rotated about a horizontal axis.

[0123]In the context of the present disclosure, typically the molten melt comprises a slurry of hard, insoluble solid refractory particles in a host metal and the cast product is a composite metal product, typically ranging in mass from 5 kg to 5,000 kg, having a ferrous metal matrix (the host metal) and comprises a non-uniform distribution of hard, insoluble refractory particles in the ferrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com