Heat exchange apparatus for circulating fluidized bed boilers

a technology of fluidized bed boilers and heat exchange apparatuses, which is applied in the direction of fluidised bed apparatus, lighting and heating apparatus, combustion types, etc., can solve the problems of corroding, exhaust gas, abrasion of the tube, etc., and achieve the effect of improving the expandability of external heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]A heat exchange apparatus for circulating fluidized bed boilers according to one exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings. While the present invention is shown and described in connection with exemplary embodiments thereof, it will be apparent to those skilled in the art that various modifications can be made without departing from the scope of the invention.

[0032]Unless specifically stated otherwise, all the technical and scientific terms used in this specification have the same meanings as what are generally understood by a person skilled in the related art to which the present invention belongs. In general, the nomenclatures used in this specification and the experimental methods described below are widely known and generally used in the related art.

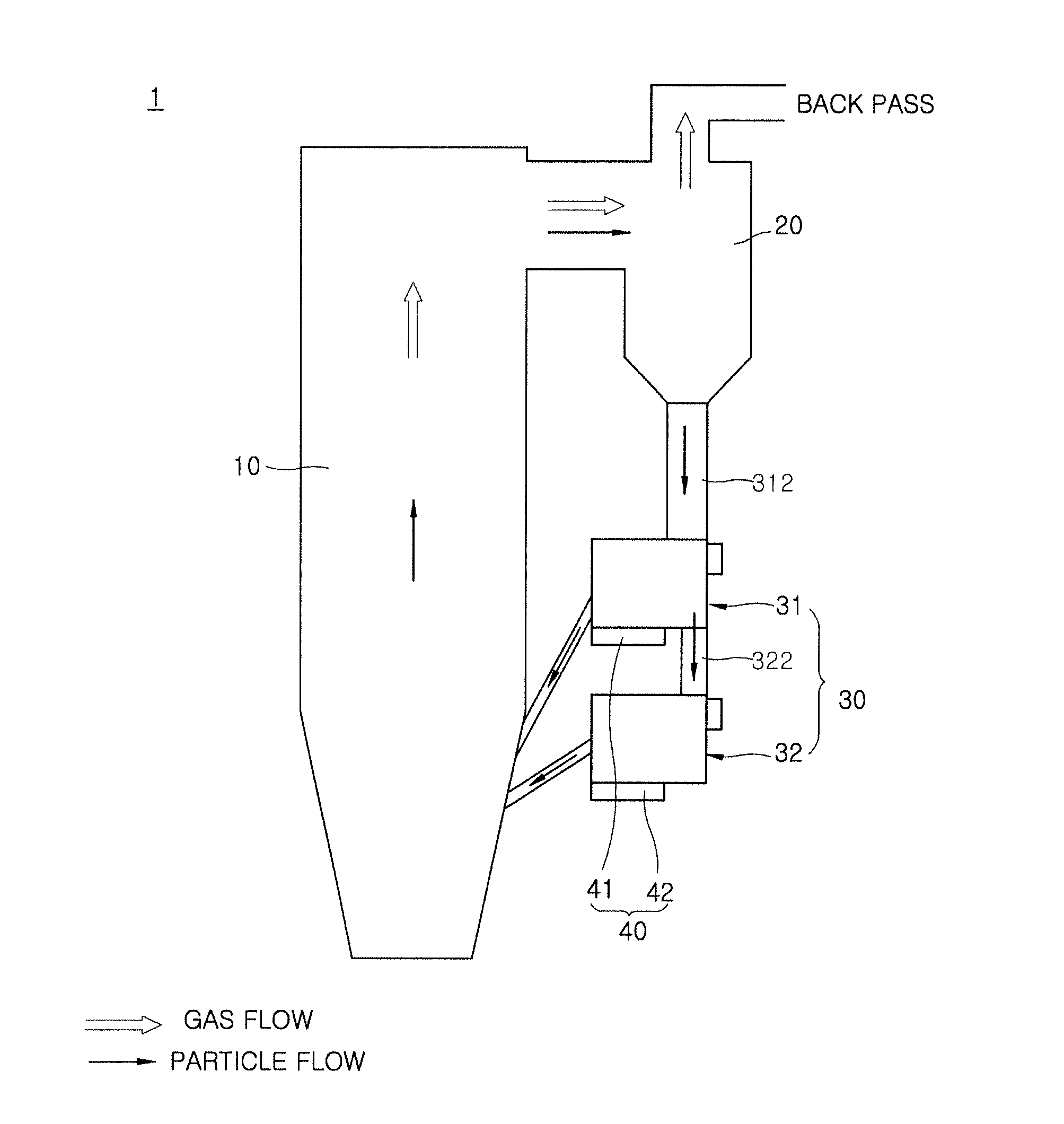

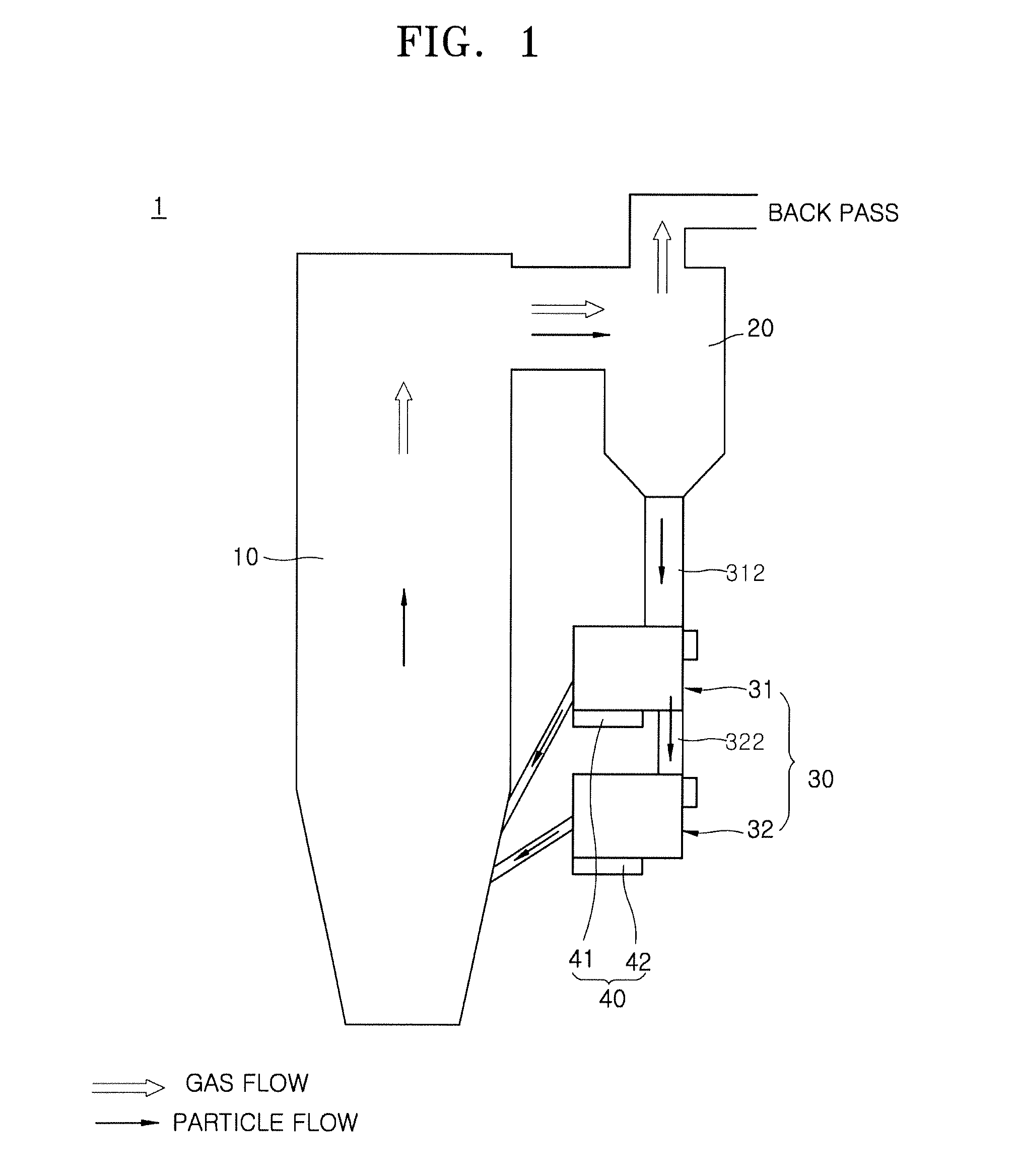

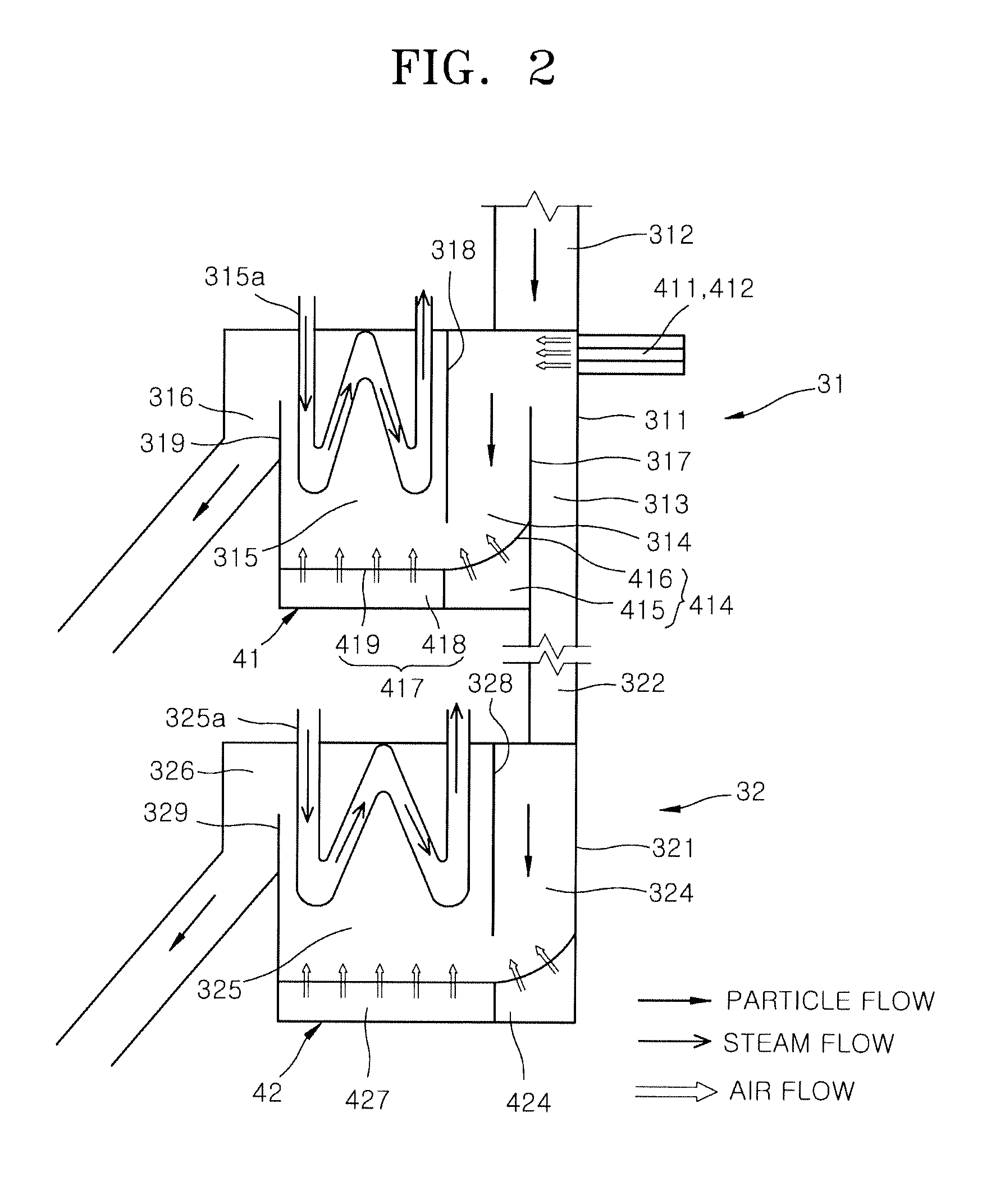

[0033]FIG. 1 is a concept diagram schematically showing a heat exchange apparatus for circulating fluidized bed boilers according to one exemplar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com